-

Posts

5,153 -

Joined

-

Last visited

-

-

Yes they can. But not in this case. If a metal cap is what you want, this particular EAP is an easy-peasy no brainer.😜

-

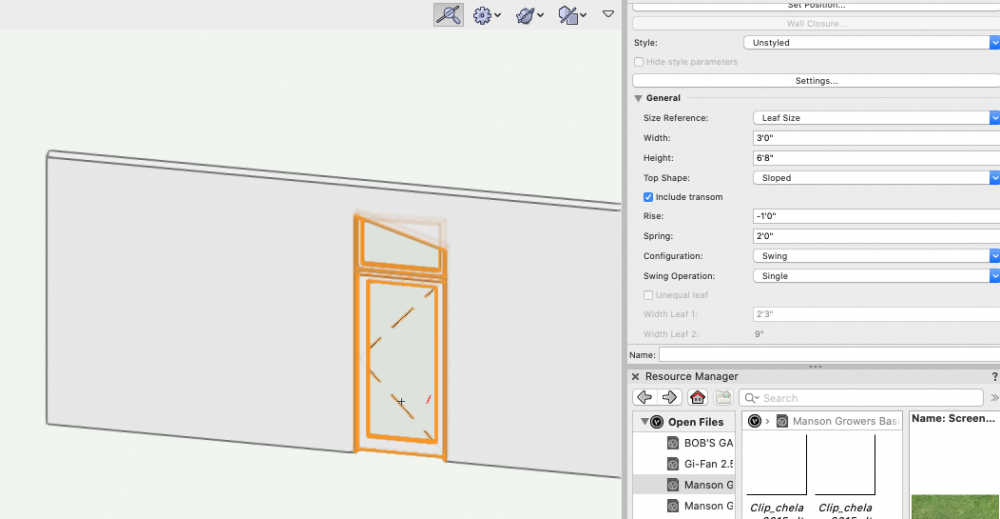

See attached. To make an EAP (extrude along path) first draw the profile, then draw the path, then select both objects and select the command Model>Extrude Along Path. You then select the path object and voila. One note, you almost always need to Edit the Profile after creation in order to get it aligned as desired. In the attached image, the cap is an EAP. This took me less time to create and adjust than it took to write this reply 😉 I always advise that you create a discreet Class for the Cap, then way you can easily choose to have it show or not in various views and viewports.

-

The Extrude Along Path command would be a good fit for this task. It's pretty easy to do and will give you what you need for model (visual) and for details (sections).

-

Change Texture of Floor in different styles

CipesDesign replied to JochenDerAllvater's topic in Architecture

Generally I use the method that most closely resembles real life, just like Tom says. (US/Imperial units): cover the entire area with 3/4" thick Floor Object for the structural floor sheathing and then create various additional 3/4" thick Floor Objects for each room or series of rooms with same floor finish. -

There are two types of Objects that I always insert into Walls: Doors and Windows. All other Objects I do not insert: Plumbing Fixtures, Cabinets, Appliances...

-

It was waaaaay back, at one of Janis Kent's (anyone remember her?) MiniCad Training Seminars, that's when I "got it". That was the best three days (of classes) that I ever spent in my life. And most of what she taught us is still relevant today. Even though VW's has changed (and not always for the better - today I'm very upset about the "new" orbit animation tool eg) the basic bones are still the same.

-

I would agree (but maybe reduce it to 7-8 times, once one is really proficient). But there is another important point here: what about the time saved at the other end, in producing Elevations and Sections? And the amazing visual presentations possible without the need of hiring a watercolorist?

-

How do I model a Saltbox Roof (Asymmetric gable)?

CipesDesign replied to MaltbyDesign's topic in Architecture

A note regarding Stories... I never use them! IMO they only made the whole user experience more confusing. That said, I *think* (someone could correct me or verify) that Stories were added to facilitate BIM/ICF capabilities. As a small one-person operation specializing in one-off residential design I don't need those capabilities. Also, IMO all the "automated" drawing/file setup tools are dangerous as they prevent the user from learning the basics of Layers and Classes and how to set up a file manually, which is really easy in most cases. Again speaking from my experience and needs. Large projects with multiple users are a different story (pun??). -

How do I model a Saltbox Roof (Asymmetric gable)?

CipesDesign replied to MaltbyDesign's topic in Architecture

Old School: Start with Create Roof(s) then Ungroup which will produce various Roof Faces. These can be easily Clipped/Added... -

Create a Section Viewport. Measure there...

-

Well, in the old days when I was building a lot, the very nice and knowledgeable people at the lumber yard did takes-offs from plans, for free... Additionally, for old-style 16" O.C. Wall Framing, we used to use 1 stud per foot, which was always a remarkably close estimate and accounted for kings and trimmers at openings and corner studs, etc. The length of the plates is easy, it's the perimeter times 3, etc. etc. Maybe you should make a bit of effort with math?? It's really not that hard. But in my mind it really comes down to a fundamental dichotomy: some people understand ALGEBRAIC type math, while others hate algebra and understand GEOMETRIC type math better. I am of the latter school, being quite a visual thinker. But you can use either one to solve the same problem(s), and even cooler, you can use one to prove the other 😉 For me the teachers I had, with one notably exception, could never get me to understand. So there's that as well...

- 9 replies

-

- worksheets

- slabs

-

(and 3 more)

Tagged with:

-

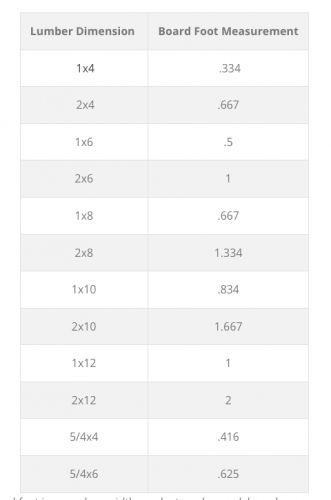

You could probably do this in a fairly simple spread sheet. The math is pretty simple. Using the attached table, all you would need to know is the total lineal footage of each size of lumber...

- 9 replies

-

- worksheets

- slabs

-

(and 3 more)

Tagged with:

-

I have complained and filed bugs regarding these issues... No joy yet. Maybe someday?

-

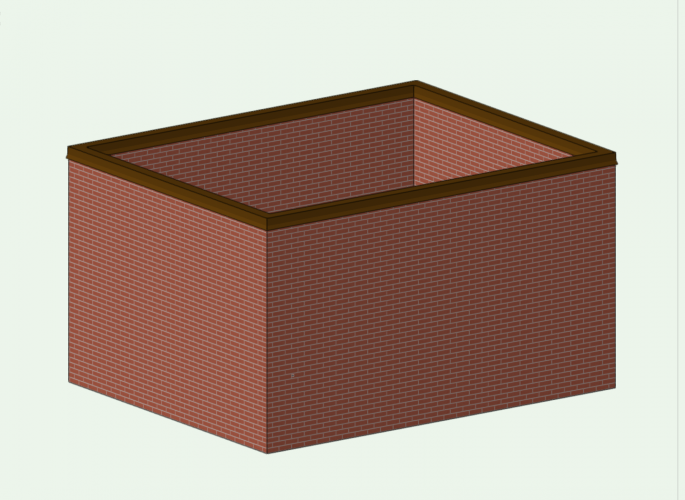

How would I create detailed brickwork for the facade of a building?

CipesDesign replied to Ami's topic in General Discussion

One way I have cheated/fudged the Wall Features won't-go-to-corner flaw is to let them go as far as they can and then create a 3d Object for the corner(s)... Not perfect, but mostly workable.- 11 replies

-

- architecture

- walls

-

(and 3 more)

Tagged with: