-

Posts

12,703 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Pat Stanford

-

how to covert hollow object into solid object

Pat Stanford replied to Lenarp's question in Troubleshooting

After you import the object into VW, what kind of object does it say it is in the OIP? You may be able to just go to the Modify menu, Convert: Convert to Generic Solids and get what you need. Sorry, but I am not willing to give cgtrader my contact information to try and help with this problem. -

Viewport Update taking ages to update

Pat Stanford replied to rafaelmartins.95's topic in Architecture

In Hidden Line they are taking much longer. All of the curved surfaces definitely impact the performance. Interesting that your version is only watermarked. The students I have dealt with recently have sent files that were not openable in the commercial version. -

Viewport Update taking ages to update

Pat Stanford replied to rafaelmartins.95's topic in Architecture

I just downloaded your file and opened it on an i9 MacBook Pro. None of the section viewports took more than about 30 seconds to update. I don't see anything in the file that should be especially difficult to handle. There are lots of curves, but they seem to have a reasonable number of vertices. Restart Computer and VW? Also, the file shows as being watermarked. Did you expect that? -

@Christiaan I think you use a Magic Mouse. Can you help Ricky?

-

Metal Parapet Flashing (Extrude along path) Visibility Question

Pat Stanford replied to MaltbyDesign's topic in Architecture

3D only objects (like extrusions) are only rendered as wireframe in Top/Plan view. You will either need to use Top view where they will render, or convert the objects to Hybrid (either make a symbol or and AutoHybrid Object using the command in the AEC menu) and give the object a "screen plane" equivalent that can display as a filled object in Top/Plan. -

I don't think there is a way to get the components using the Data Stamp. Hopefully someone will point out that I am wrong.

-

How do you wrap an extrusion around a curved shape?

Pat Stanford replied to Ami's question in Troubleshooting

Mark's idea will work only for a single direction of curvature. If you are trying to make panels that are part of the hemisphere and therefore have to bend in multiple directions that idea won't work. I don't think there is a way in VW other than to possibly model a flat panel and then use the Deform tool to bend it in multiple directions.- 7 replies

-

- interiordesigner

- 3dmodelling

-

(and 1 more)

Tagged with:

-

Your quotes and parentheses are also different in the different cases. Some have the quotes on the outside, others have the parens on the outside. Since searchcriteria must be a string, are you possibly not getting the criteria you think in some cases?

-

Trouble subtracting columns in worksheet

Pat Stanford replied to Kennedyme's question in Troubleshooting

Let's try this again. -

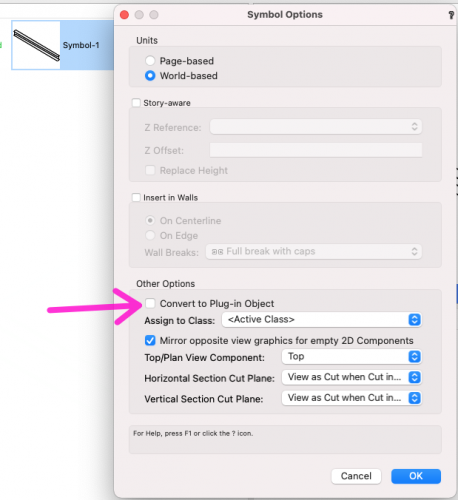

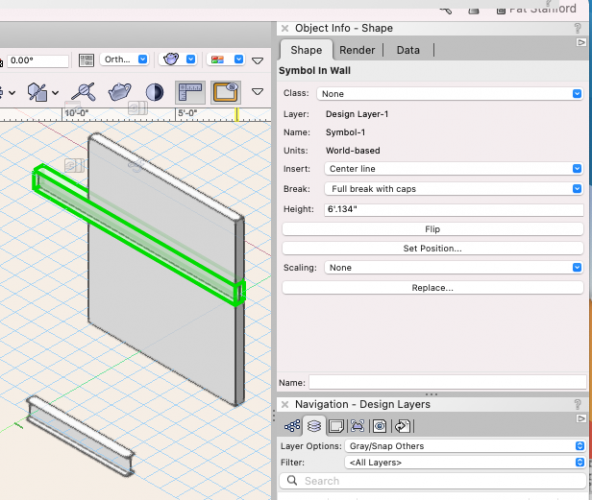

Do you have the Symbol Options set to Convert to PIO? And to Insert in Wall? I was able to insert a beam made into a symbol into a wall.

-

Trouble subtracting columns in worksheet

Pat Stanford replied to Kennedyme's question in Troubleshooting

Here is the thread about this back at the end of 2016. The basic issue is that you can't do math on SUMmarized values. See the note about it being working as designed. I will try and find some time this afternoon to see if I can figure out a work around. -

No selection options in Object Info>Render

Pat Stanford replied to DR.'s question in Troubleshooting

Renderworks was bundled into VW back in 2017 or 2018 (or maybe earlier), so if you are running a semi-current version it should say "Designer, Renderworks". Three steps: 1. Try and Delete you License and reenter it and see if that works. 2. Try and uninstall and reinstall VW. I would also delete your User Preferences file at the same time to make sure you have to reenter the serial number. 3. Contact Tech Support / Customer Service at Vectorworks to see what is wrong with your license. Good luck. Vectorworks will help you with this. -

Trouble subtracting columns in worksheet

Pat Stanford replied to Kennedyme's question in Troubleshooting

I have to go back through my notes, but the idea of SUMmarized subrows calculating independently and not being able to be used for mathematical calculations is Working as Designed (WAD). I think there was some kind of work around but I can't remember what. I will find that thread later today and respond again. -

It is likely that the next generation of Apple Silicon will be out by summer. I say you should wait. If you needed a machine today (e.g. your machine burned up in a fire) I would suggest M1. But if you have a machine that is close to the M1, why spend the time to switch when you will just regret not waiting a couple more months.

-

No selection options in Object Info>Render

Pat Stanford replied to DR.'s question in Troubleshooting

Does this happen in every file and with all object types? If so, it sounds like Renderworks has somehow gotten turned off. If you go to About Vectorworks, what does it say under Licensed Products? -

Trouble subtracting columns in worksheet

Pat Stanford replied to Kennedyme's question in Troubleshooting

What is the formula in Column C? -

Same Record Formats in all presentation sheets

Pat Stanford replied to Verve's topic in General Discussion

Short answer is No. Once a Record is attached to an object, it is independent of the Record defaults and the data attached to any other record. The longer answer is there may be work arounds. 1. Take a look at the Title Block Border object. This can be placed as just the Title Block so you don't get the border. Any it offers both Project and Sheet specific fields. If you change a Project field it is updated on all of the TBB objects. 2. You could create a master Worksheet to edit the data in. You would still need to copy/paste to each row of the database, but at least all the information would be in one place and you could easily see if something does not match. 3. You could use Custom Modification to edit all of the objects at the same time. But if someone forgets and only edits a single instance you would not see it without comparing the different sheets. 4. You could write a script that would let you enter the data and then store it to each instance of the record. Ask again if you need more help. -

Check in the Organization Palette that the Sheet Layer DPI is set to something greater than the default 72 DPI. I personally find 150 sufficient, but there are others here who prefer 300 or even 600. Just remember the higher the DPI the longer renders will take. 300 takes 4 times longer than 150. 600 takes 16 times longer than 150. If you are doing test renders you are often better off setting the DPI down to something low so you can adjust and get the lighting to cast the shadows where you want and then turn up the DPI for final renders.

-

No selection options in Object Info>Render

Pat Stanford replied to DR.'s question in Troubleshooting

Have you tried restarting VW? -

Team workspaces - save to workgroup folder

Pat Stanford replied to Ross McLee's question in Wishlist - Feature and Content Requests

I don't think you want people using the same workspace from a Workgroup folder. Things like palette positions are saved to the workspace file when you quit VW. If you save first, your preferences will be overwritten when the next person quits VW. So you will never know what settings you will get when you restart VW. -

If you are using a Custom Workspace you will need to edit it. Or for a quick trial, just switch to one of the default workspaces.

-

Importing McMaster Carr drawings

Pat Stanford replied to DWrightLocal80's topic in General Discussion

I have not downloaded a lot of file from McMaster, but I have imported a few and a lot of parts form other vendors. I personally have liked the STEP and IGES imports best. With McMaster, I think you will probably need to try different imports for different parts. I am relatively certain that McMaster is only packaging the models provided by each component manufacturer, not generating their own. So different components are likely to import differently. Suggestions: 1. Always import into a blank file until you are certain that the import works OK. You don't want to have something come in with multiple classes you will have to clean up in your main file later. 2. Think about what is important to your future use. If you only need the geometry then a model that comes in as a single Generic Solid might be OK. But if you want to be able to apply different colors/textures on different parts, then you need a different level of detail. 3. Consider "cleaning" up the models. Depending on how the models were created and what you eventual use is, it might be worth the time to "de-detail" the models. If these are parts of a relatively large assembly, then you might not need each of the 1/16" filets on every edge (for example) and you might get far better rendering performance on something with straight edges. -

Speak for yourself Michael. ;-) On your mark, get set, GO!

-

"harvested" = "borrowed" = "stole". Which Rule of Acquisition is that? OK Klaars, you win this round, but watch your back. ;-)

-

Printing and Publishing

Pat Stanford replied to hollister design Studio's question in Wishlist - Feature and Content Requests

It actually sounds like at least partially a printer driver problem. When I print to my Canon 2525 laser printer (11x17), it all spools at once. If you are having to submit each job individually it is not a VW problem, but rather an Epson problem.