-

Posts

550 -

Joined

-

Last visited

Reputation

453 SpectacularPersonal Information

-

Occupation

I make real fake things.

-

Homepage

www.evanalexander.com

-

Location

United States

Recent Profile Visitors

5,783 profile views

-

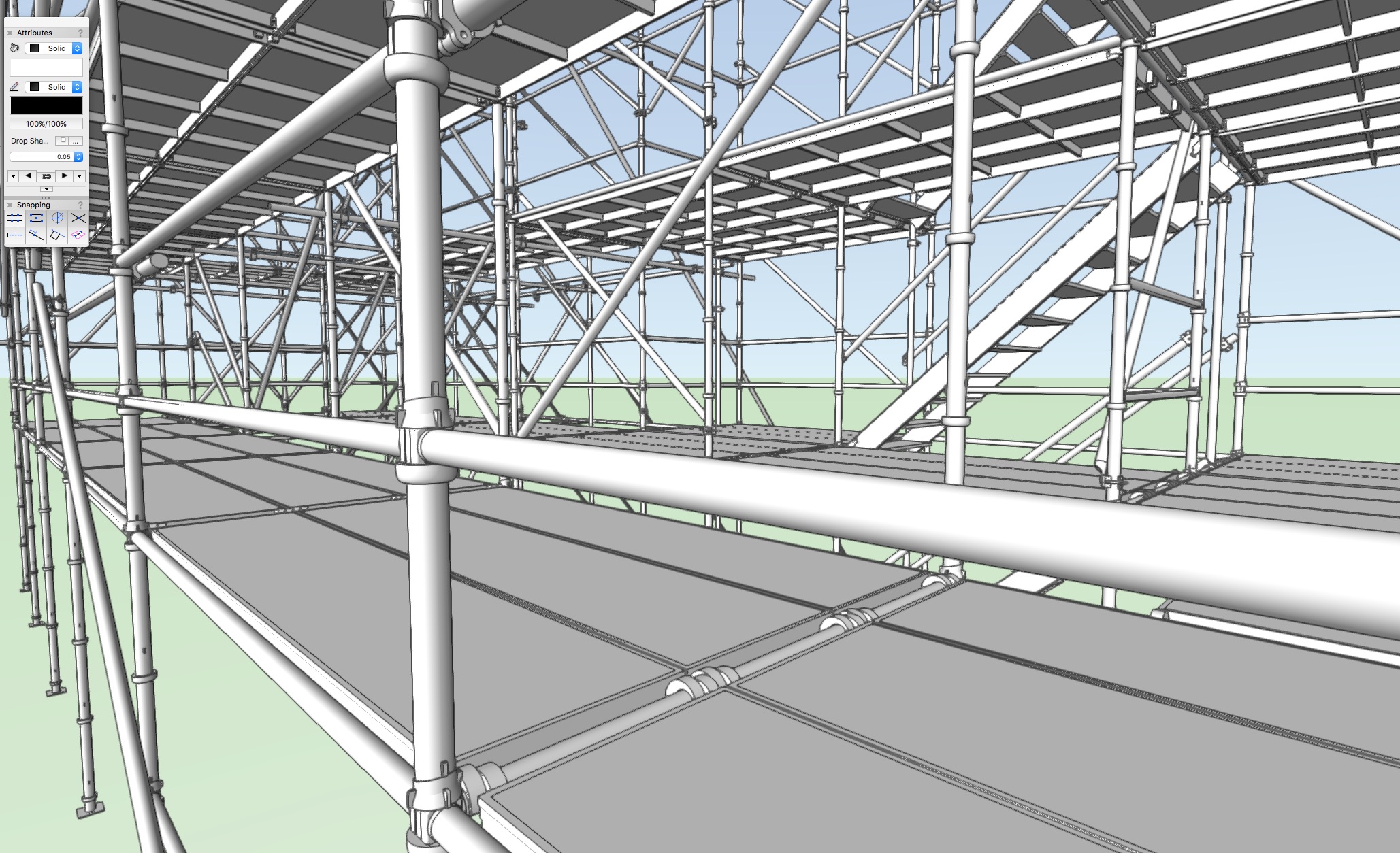

My go to for things like this is Background set to with Final quality renderworks or Shaded (but with edges turned off) and then Hidden line for the Foreground render. Gives the best of both worlds.

-

I haven't looked at it in a while, but I think Fusion 360 has capabilites that might suit your needs?

-

Hi! I realize this is a Vectorworks Forum, but I imagine a lot of members also work with Cinema4D for entertainment visuals. I have just released the ML Light Kit. https://www.evanalexander.com/ml-lightkit The ML Light Kit for Cinema 4D and Redshift are tools designed to render and animate moving lights easier, faster and more realistically. Built for illustrators and concept artists, these tools are great for developing visuals for concerts, events, theater or any project requiring precise visual lighting. The ML Lights are non-brand specific instruments that look great at any viewing angle, and keep the polygon count low. Custom user controls make focusing, coloring and adding gobos right at your fingertips. The system is designed with simplicity in mind to speed up your workflow. Overview video here: https://youtu.be/_Cp-g5Kefi0

-

Fill not Appearing on 2D Linework imported from Sketchup

EAlexander replied to Micaela Edwards's question in Troubleshooting

Is it a polygon or 16 lines? If it's 16 lines, go to Modify>Compose to join them and then add fill. If it's a polygon, post the file so others can take a look. -

Round top and extended round base model for 3D printing or milling

EAlexander replied to WhoCanDo's topic in Solids Modeling

This whole thread makes me happy. You're all nerds and I am here for it! Great info being shared. -

This actually sounds like more of a snapping issue - have you checked your snapping palette to see that you have the correct modes turned on?

-

Just to be clear: A 2024 file will never open in 2022 without being exported as a backsaved version from 2024.

-

Do you have a slab object in the file? VW doesn't like name sharing with any kind of object or organizational label, not just other classes. Can you use: Slab_ Slab01 SlabClass etc. ?

-

Expand the use of the 3D Dragger

EAlexander replied to MGuilfoile's question in Wishlist - Feature and Content Requests

I made a wish list about the functionality of this tool - please review and upvote. -

Did not know this. Excellent. I usually set up the first sheet and then all other sheets are a duplicate of the first sheet, so this isn't an issue for me, but good to know!

-

Are you rendering to a viewport on a sheet layer? By default - sheet layers have an DPI of 72 (low). Right click on the name of your sheet in the Navigation palette and choose edit - from here, up the resolution of the sheet and see if that helps. Each sheet is independent, so if you have multiple sheets, you'll have to do this to each one. And, obviously, the higher the DPI, the more time it will take to render. If this isn't the cause of your issue, can you post a file for us to look at?

-

A Master 2d Detail Library & 3d Model

EAlexander replied to digitalcarbon's topic in General Discussion

I just make a dedicated layer and drop all my details on there as symbols. They appear around the drawing as needed, but I viewport them from a sperate independent layer where things never move. Since they are symbols, I can update them anywhere and they will globally update. Also - you need to make a Wishlist request thread for this and let people vote on it if you want the devs to seriously look at it. -

Hi, Looking at your screen grab - at the top center it says "symbols/Plug-in Objects" with two blue arrows. Click that and Set it to ALL RESOURCES. Right now you are filtering your project resources to only show symbols or Plug in objects. e.

- 1 reply

-

- 2

-