-

Posts

1,331 -

Joined

-

Last visited

Reputation

893 SpectacularPersonal Information

-

Occupation

Product Planner

-

Location

United Kingdom

Contact Info

-

Skype

Leftklick

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Short answer: yes. We did not forget about this. We have this firmly in our gunsights but there are some dependencies which we will need to resolve first. Thanks for your patience and sorry for the long wait!

-

I don't think we're doing anything here. It's entirely a macOS system thing.

- 99 replies

-

- 2

-

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with:

-

VW 24 menu and pallete font change

Stephan Moenninghoff replied to LeeElston's question in Troubleshooting

Hi @LeeElston text has indeed decreased in size somewhat. Sorry about the inconvenience this is causing you! I am sure you probably know this already but for what it's worth: you can incease text size in the Windows system setings, in case that is an option for you. -

Hmm, that's interesting. I just tried on Windows and I am seeing the snaps. Are you able to file a bug for this?

- 99 replies

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with:

-

Did you mean the scaling?

- 99 replies

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with:

-

Amanda McDermott started following Stephan Moenninghoff

-

Reports able to span 2 pages

Stephan Moenninghoff replied to Joe Golden ENT's question in Wishlist - Feature and Content Requests

I would love to understand your dream world a little better 🙂 . Could you post/DM with an example? -

Reports able to span 2 pages

Stephan Moenninghoff replied to Joe Golden ENT's question in Wishlist - Feature and Content Requests

I tried to reproduce this but I was not successful. In a Vectorworks worksheet, adjacent cells seem to share borders. You can turn the border on and off between any two cells from either of the two neighbouring cells. This is not the same as, for example, html, where each cell has its own border (and that comes with other quirks, like border-collapse properties etc.). If this does not work for you reliably, that sounds like an edge case or a bug. Do you have a sample file that demonstrates this? Could you share this file? Thanks! -

Reports able to span 2 pages

Stephan Moenninghoff replied to Joe Golden ENT's question in Wishlist - Feature and Content Requests

anything in particular you need? -

bjoerka started following Stephan Moenninghoff

-

That's a bug. Thanks for letting us know! Could you share your screen resolution and UI scale preferences from your Windows settings as a screenshot here? I will try and reproduce it on my end to get it fixed.

- 99 replies

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with:

-

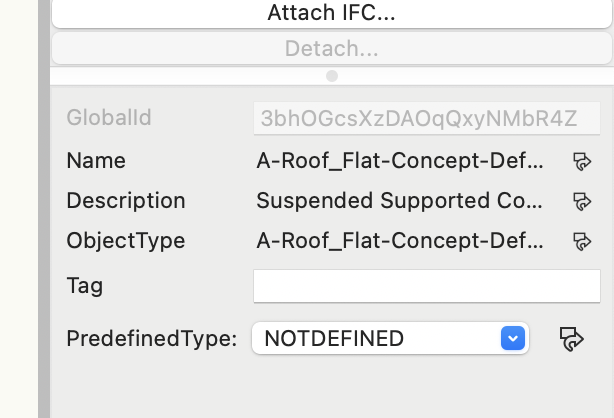

@Christiaan I have changed the wording of the alert for an upcoming task anyway because I found the same thing. Here is the proposed new alert. If this can be improved even more, I am sure we will be happy to do so.

-

3D dragger oversight is killing me

Stephan Moenninghoff replied to Kaare Baekgaard's question in Wishlist - Feature and Content Requests

Hey @Kaare Baekgaard I just tried and I cannot quite reproduce this. It seems to snap where it should. Can you attach your test file? -

Display the layer scale in text in View Bar compact mode?

Stephan Moenninghoff replied to GVMaEGjs's question in Troubleshooting

This is a Windows bug which we have logged to be fixed. Thanks for reporting!- 1 reply

-

- 1

-