-

Posts

27 -

Joined

-

Last visited

Reputation

39 GreatPersonal Information

-

Occupation

Architect

-

Homepage

www.Kwaske.com

-

Location

United States

Recent Profile Visitors

1,212 profile views

-

Architect's Sign Seal on Sheets - Easiest Method?

Ron Kwaske replied to Shortnort's topic in Architecture

I would manually class all the stamps separately: eg: Stamps-Arch, Stamps-SE, Stamps-PE, Stamps-CE. And then have only the respective stamp class turned on, on its coordinating title block. To make life easier, you could then create a script to turn them on or off as needed. -

Architect's Sign Seal on Sheets - Easiest Method?

Ron Kwaske replied to Shortnort's topic in Architecture

You would need to class the stamps and signatures separately by discipline. I do the same depending on the state I am working in. You can then either manually turn the classes on or off; or, create a script to do it for you. As mentioned in my previous post, I created a script to turn my stamp(s) and signature(s) off and then turn a 'not for construction' label on in its place. -

Schedule of Values (Contractor Budget)

Ron Kwaske replied to Scott Schwartz, AIA's topic in Architecture

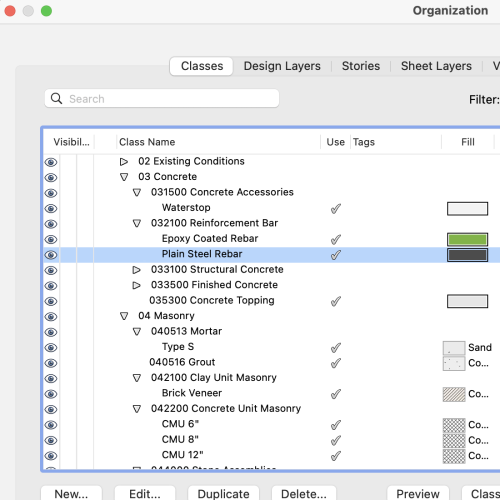

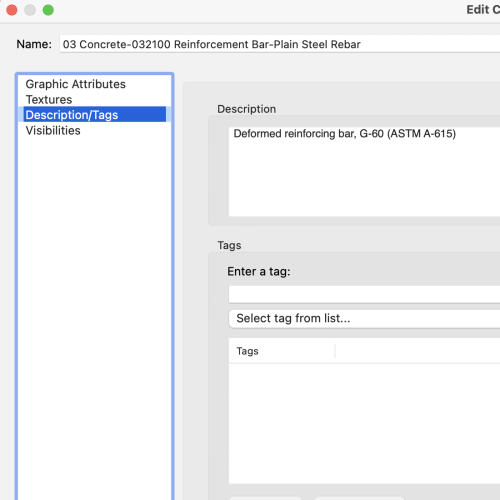

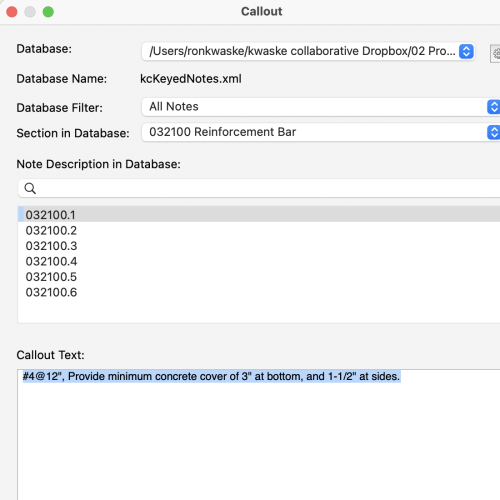

I don't link my specs to my callouts- I use them for different purposes. - I use the description in the classes (organized by csi) for general material notes and call it out via a custom data tag - I use keynotes organized by csi to provide detailed instruction usually in details and section views. - Finally, I have my specs just as text in a library that I group by section. I manually place and modify them as necessary. I have modified my spec format, still using a 3-part system, but streamlined attempting to make it easier to read. Note that I do not do government work and I am very aware that on small, non-institutional projects, few actually read the specs cover to cover, so I do my best to keep it 'friendly.' -

I manually enter the finish on the 'room finishes' tab in the space object. I don't know of any way to get a slab object 'talk to' a space object.

-

If I have a floor with many different finishes; I configure my slab so that the top finish is the subfloor. Then, I create extrusions for the floor finish and class them accordingly. This method is really advantageous to detail thresholds if you are careful about the actual thickness of the floor finish.

-

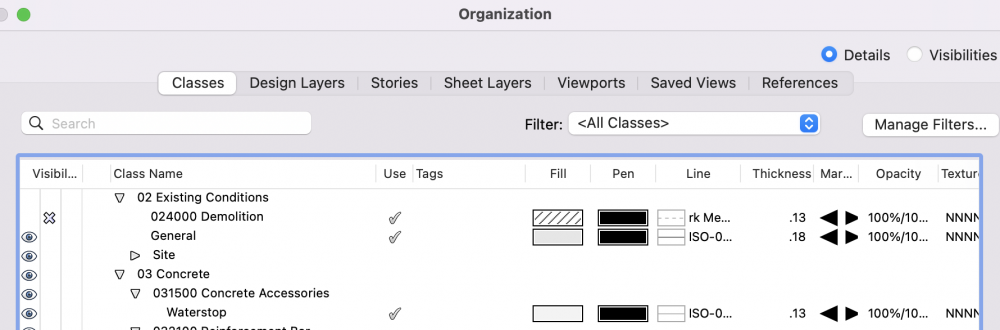

Schedule of Values (Contractor Budget)

Ron Kwaske replied to Scott Schwartz, AIA's topic in Architecture

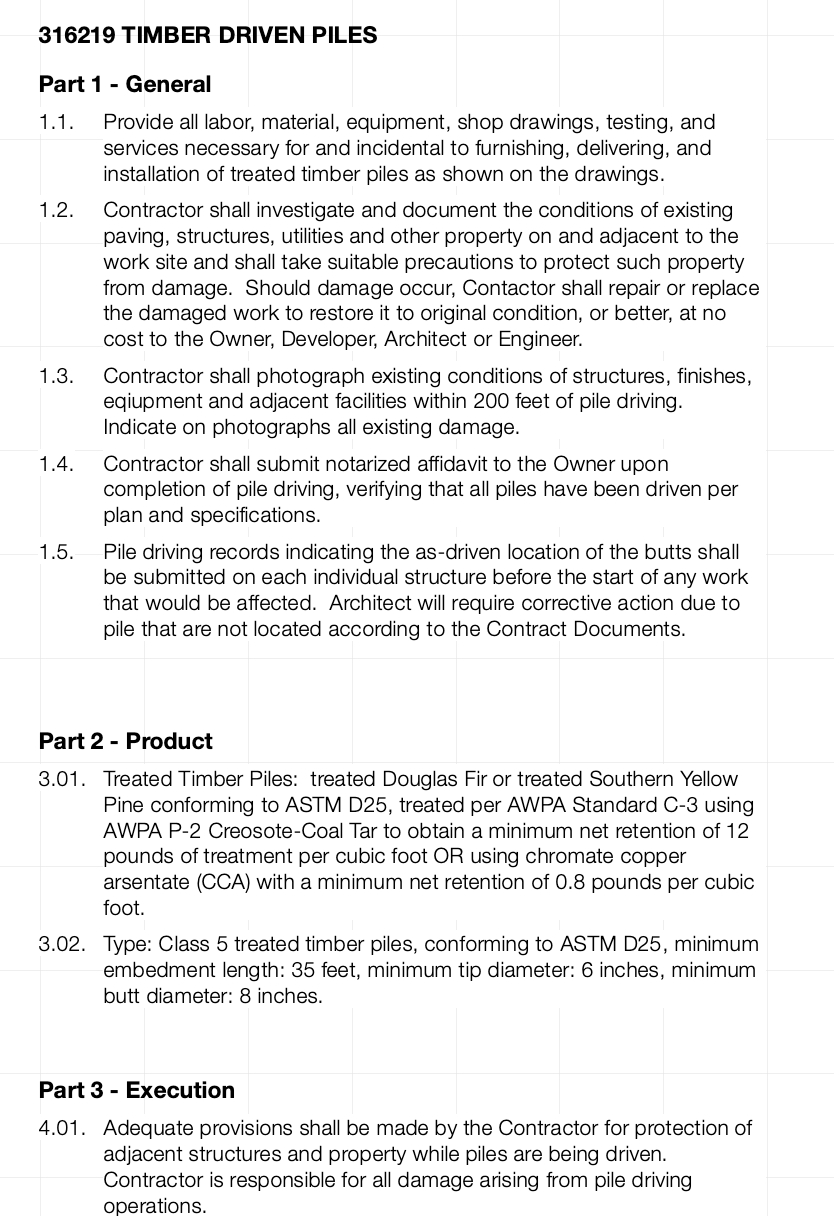

To keep things nice and tidy, and in an attempt to make it easier on the construction end; All of my classes are organized by CSI Masterformat. Within the class, I add a very general description that I can call out via a custom data tag (usually for calling out a material type). Likewise, all of my keynotes are organized by CSI, and I use these for very specific notes to call attention to (usually for calling out a supplier/or equal, or some other minimum criteria, or standard of quality or performance ). -

I think it easier to just model the stair system. This way, you have complete control, and, you will have very little detailing to do on the back end.

-

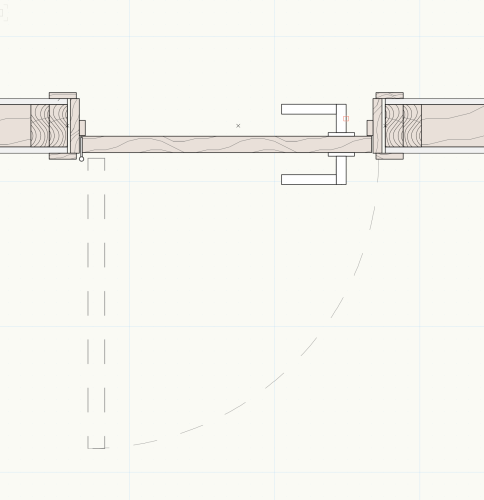

Offsetting the rim from the jamb to make room for hinge in BIM.

Ron Kwaske replied to Meret's topic in Architecture

From my experience; 3d symbols are often best modeled in VWorks instead of importing from other sources (I have found restaurant equipment notoriously bad to import). A properly modeled symbol using 3d solids and, taking advantage of the correct 'show detail' levels will dramatically decrease processing / rendering time. -

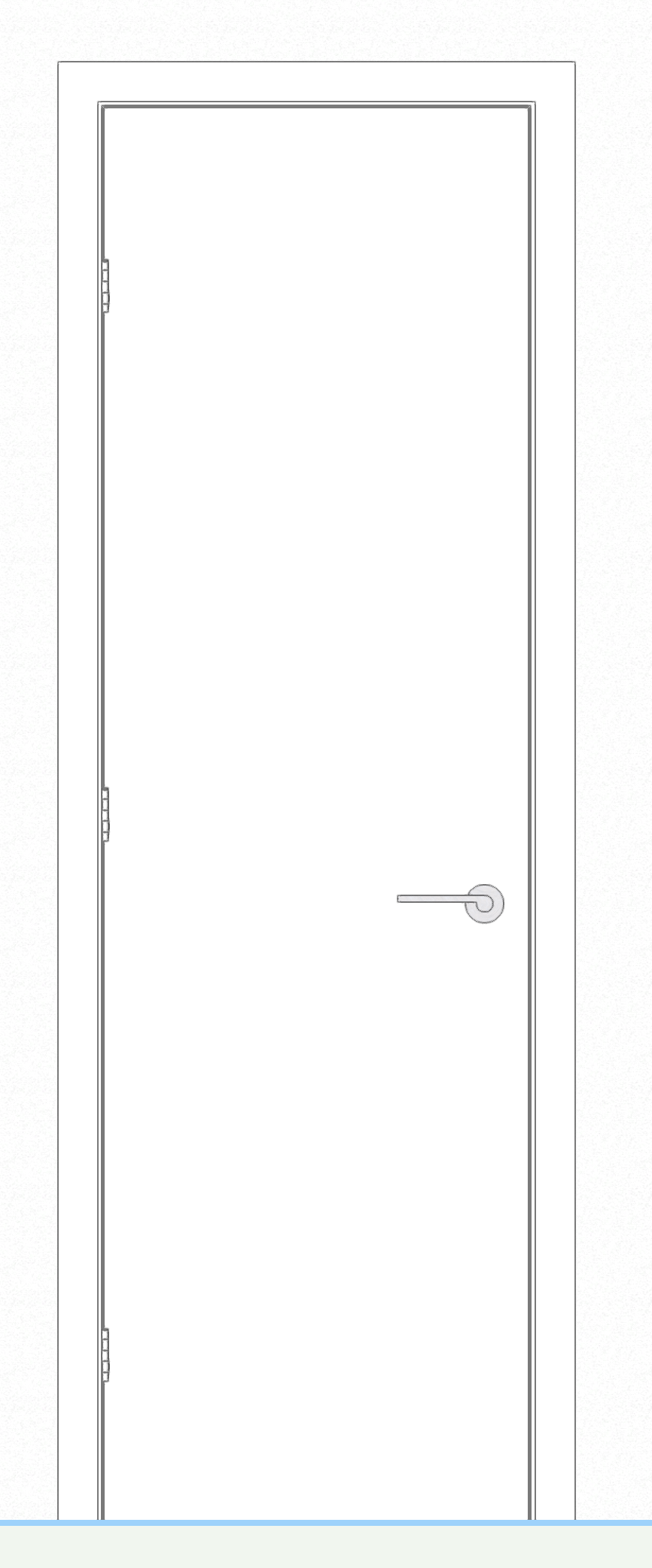

Offsetting the rim from the jamb to make room for hinge in BIM.

Ron Kwaske replied to Meret's topic in Architecture

100% modeled and then turned into a symbol. I've done this for most of my 'stock' doors - both wood framed and hollow metal. -

Model it! I do a lot of work with pre-engineered metal buildings - either rehab, or new with unique architectural features. Like timber frame, there is a lot of redundancy, so, I create custom symbols of major components. Be sure to use symbols as much as you can- both for ease of changes; but, also to help manage the file size.

-

I use Morpholio and Vectorworks all of the time. I've nearly eliminated all paper from the office, -sketching and taking notes digitally. At the start of a project, I document existing conditions to scale in Morpholio, then, export to PDF and import to Vectorworks. I then scale the sketch, and 'trace' it in Vectorworks. What I really like about this process is that by having the sketch on its own design layer, I also have written notes and observations for immediate reference - really helpful for renovation work. I also use Morpholio to take a photo to then markup exact field conditions. Finally, as a project is being fully developed in Vectorworks - I then like to export to PDF back into Morpholio where I can verify dimensions, and take notes. It becomes a very efficient and circular process. Sketch.pdf hvvac.pdf Markup.pdf

-

Offsetting the rim from the jamb to make room for hinge in BIM.

Ron Kwaske replied to Meret's topic in Architecture

Easiest to just model the door the way that you want. I do agree that doors, windows, etc. should be modeled accurately instead of using antiquated symbols as if we were still drawing by hand. -

Ron Kwaske changed their profile photo

-

It won't do it automatically; but, you can set the vertical grid for any size panel you want. From the edit wall style of the curtain wall; go to Vertical Gridlines on the far left and change the spacing. If the spacing along the length of wall is not the same, you can add as many as you want.

-

I put ALL items that are existing under one class labeled 02 Existing Conditions - General (this includes everything from walls to fixtures). And then as I begin to demo items I change the class of that item to a Demolition class. eg: a section of wall that needs to be demo-ed: I break the wall in the locations I want it removed, and change the class of the piece I want removed from Existing Conditions to Demolition. This then allow me to easily create a demo plan by turning the demo class on. For new work, I leave the existing conditions class on, turn demo off, and begin modeling new. hope this helps.