-

Posts

654 -

Joined

-

Last visited

Reputation

243 SpectacularPersonal Information

-

Location

Holland

Recent Profile Visitors

-

Anyone tried working with Intel ARC integrated graphics?

Bas Vellekoop replied to jmcewen's topic in Hardware

I can recommend the zephyrus g14 of asus, take the top model in the serie. https://rog.asus.com/laptops/rog-zephyrus/rog-zephyrus-g14-2024/ Dedicated nvidia chip up to 4060 if im correct Great screen Greats size Great processor if you do some rendering Looks are nice as well Take the one with minimum of 32 gb ram and best grahpics card and processor I have 2022/2023 model. Its lightweight and small enough for my daily travels from and to the studio by bike. It is my workhorse and have no separate desktop. Biggest complaint is battery time, it is like 2 hours. If thats is a problem then go for a Apple macbook, because all intel and amd based laptops with some punch have this problem. -

Nope, there is not. (For these kind of things I switched to Fusion360)

-

Unwanted face overrides in VW 2022

Bas Vellekoop replied to Kaare Baekgaard's question in Troubleshooting

Any change that this still gets implemented on grouplevel? Would be very handy indeed 🙂 -

Christiaan started following Bas Vellekoop

-

Tobias Kern started following Bas Vellekoop

-

VW 2023 - profile line is gone in section viewports

Bas Vellekoop replied to drelARCH's question in Troubleshooting

Here you go 🙂 https://app-help.vectorworks.net/2023/eng/VW2023_Guide/LandingPage/New_features.htm?rhsearch=whats new&rhhlterm=what new Loving all te new features!- 7 replies

-

- 2

-

-

- 2023

- profile line

-

(and 1 more)

Tagged with:

-

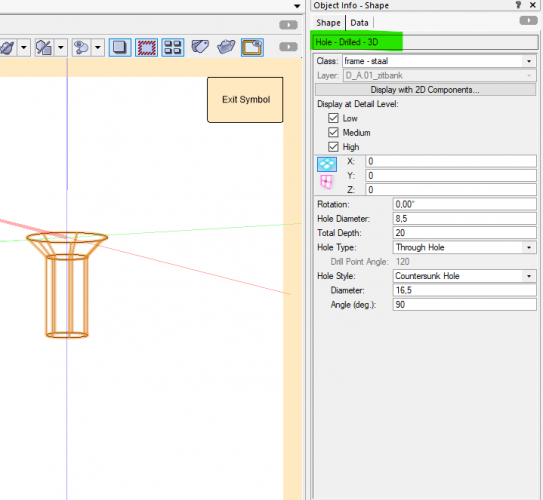

Since version 2021 or 2022: if you make a symbol of the 'hole - tapped' object then you can change al the made subtractions by editing the symbol. Ideal because you cant forget one. (Instead of going into the different solid substractions and having to edit them one by one)

-

Associative Dimensioning on 3d models

Bas Vellekoop replied to Bas Vellekoop's question in Wishlist - Feature and Content Requests

Bump 🙂- 7 replies

-

- associative

- dimensions

-

(and 2 more)

Tagged with:

-

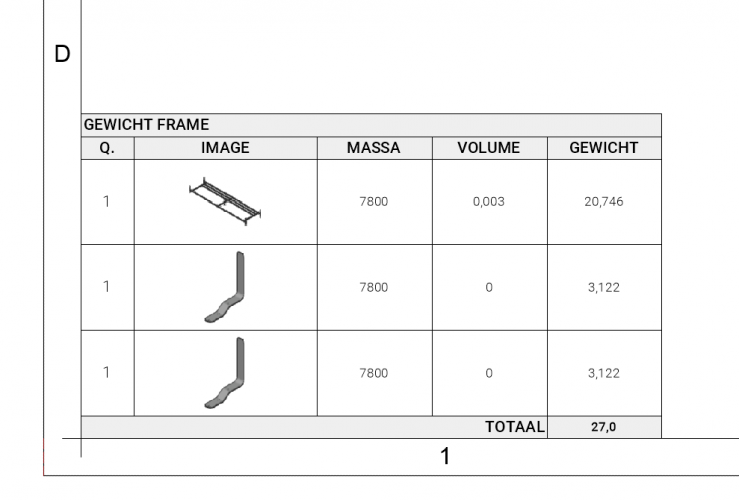

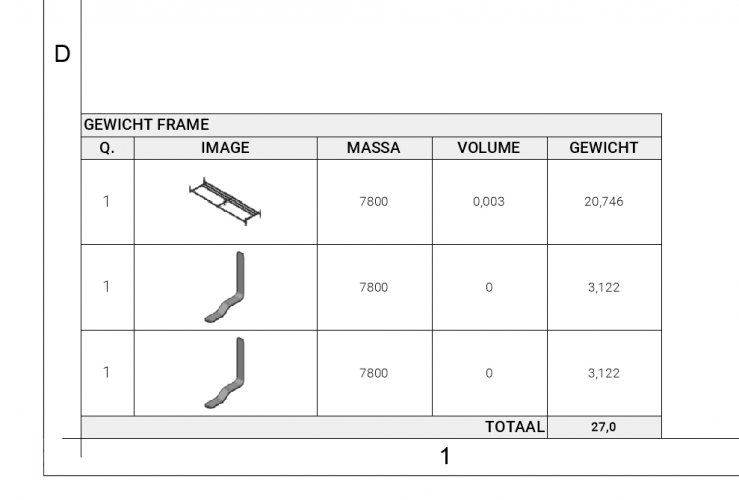

Calculate weight from volume and density

Bas Vellekoop replied to Bengt Nilsson's topic in General Discussion

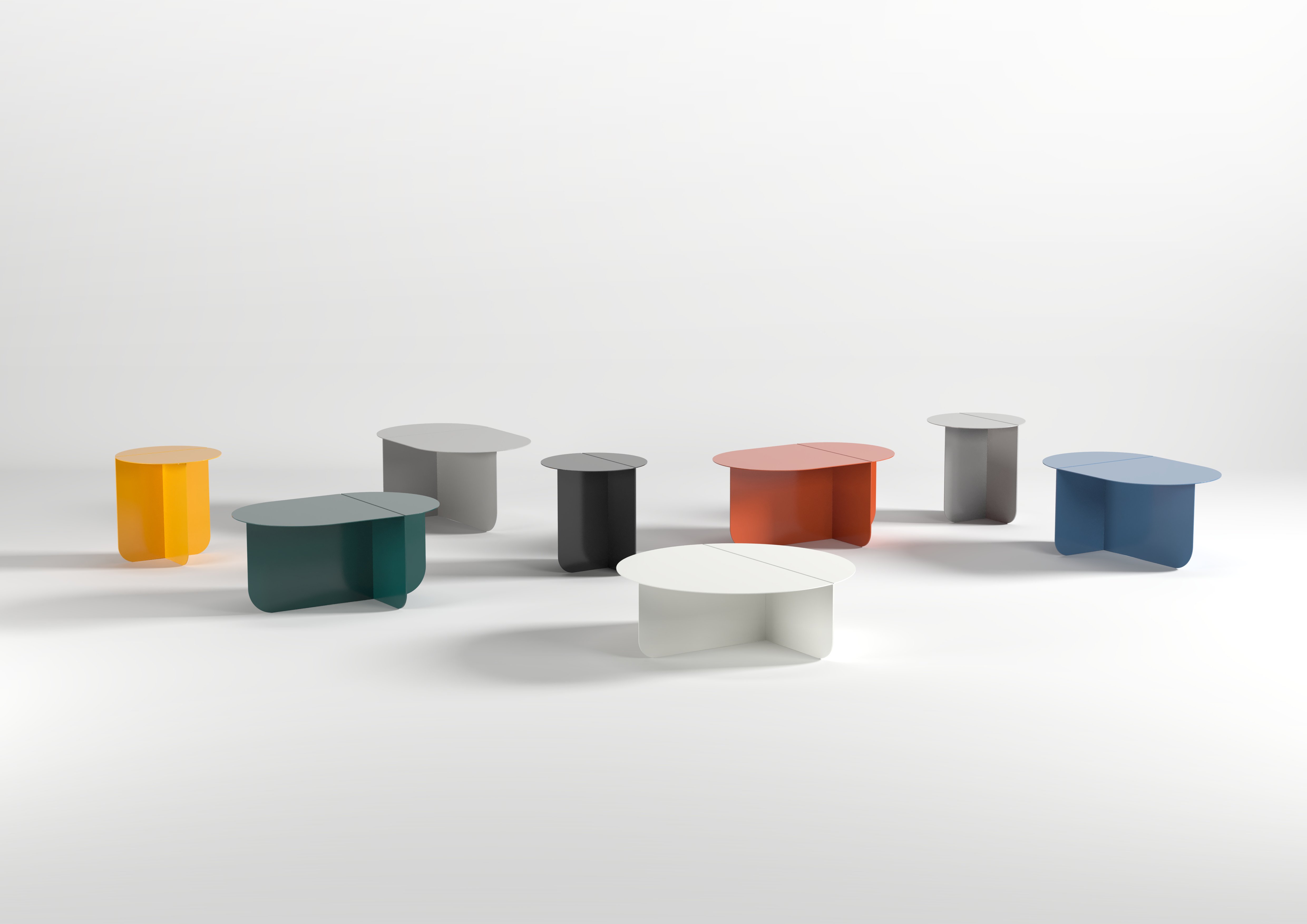

The new material resource is probably the way to go in combination with worksheets. In the past for product design i used it quite allot as can be seen in the attached picture. Then i used symbols and classes to get the right objects in the worksheet. This example is a sofa. But i used ut for the calculation of the weight of chandelier as well. It's good to know if the electric cord wil hold it 🙂- 5 replies

-

- workflow

- total weight

-

(and 1 more)

Tagged with:

-

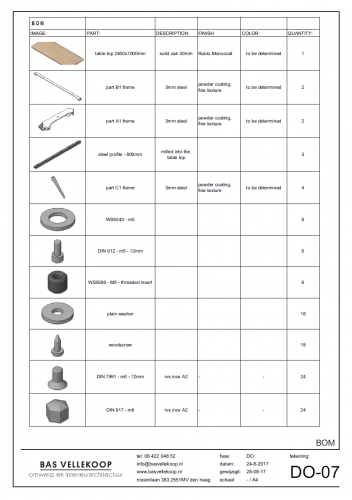

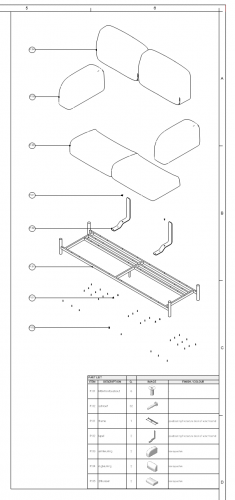

Using symbols for furniture design components.

Bas Vellekoop replied to Bruce Kieffer's topic in General Discussion

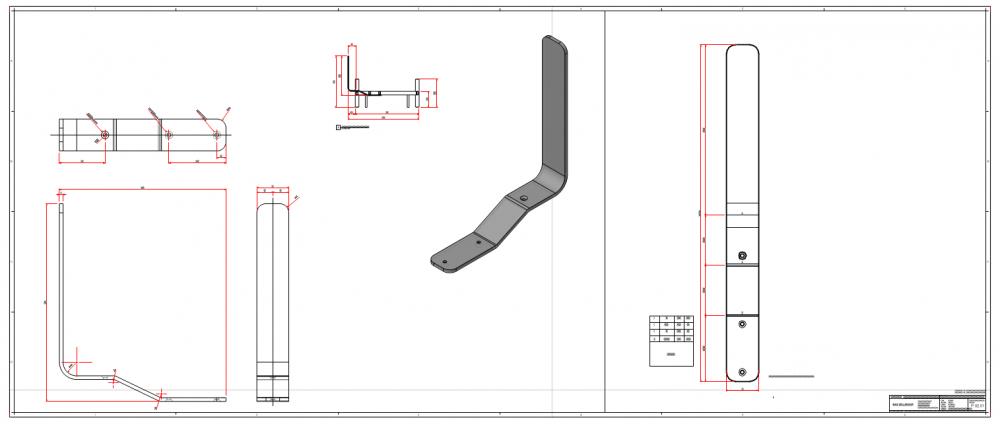

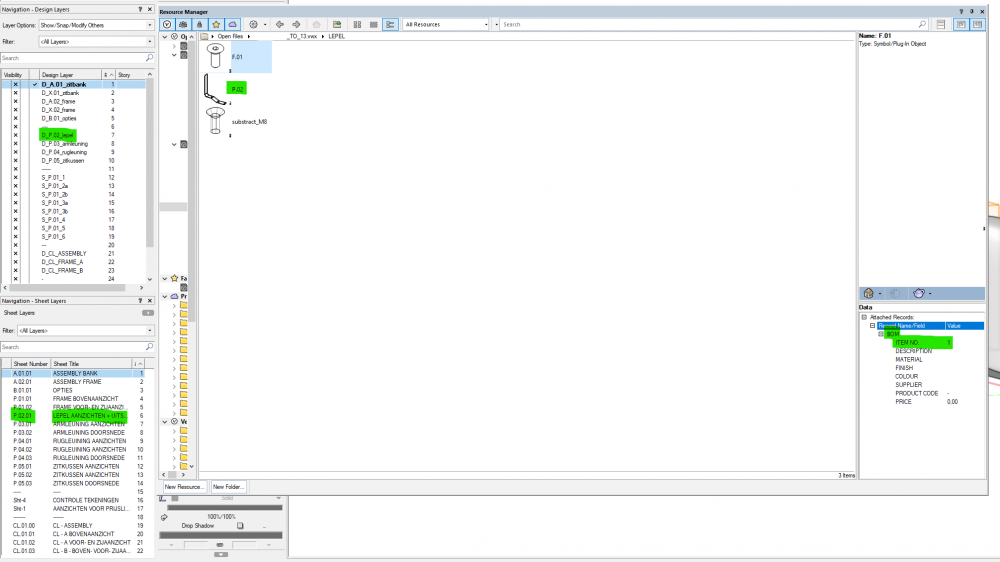

For screws etc it is great. For other parts of the design in my experience as well. With the option 'show other objects while in edit mode' editing is as easy as it would be just an object in the drawing. Its just right mouse click > edit 3d component With the creation of symbols of all the different parts of an (sub) assembly it is fairly easy to create separate design layers where you put each individual symbol on. You can use these design layers for easy for editing (if needed), and they are ideal for setting up sheet layers of each individual part for annotating and dimensioning. The only thing I`m really missing is auto updating dimensions as in Fusion 360 or other more product design focused programs. auto updating dimensions would save allot of time and possible faults. Automatically filling record or worksheets with length height with is not possible, but records for the creation of a Bill of Material can be very handy. This is a fairly simple one: In combination with Data tags and design layer viewports it is even more fun 🙂 And with some simple math you can get weight of your design and can change your design if that is needed based ont that. And if you just want to show and annotate parts and create flat patterns with the bending lines etc. 🙂 : So allot is possible with symbols 🙂 -

Using symbols for furniture design components.

Bas Vellekoop replied to Bruce Kieffer's topic in General Discussion

When i did furniture design in VW I made extensive use of symbols. I would highly recommend it. I created a system where symbols < > design layers <> sheet layers correspond with each other. You have to keep your file clean and organized, but it works pretty great. All my parts had a P of product, all subassemblies an SA, and assemblies an A. following with a number. Attaching a record format to the symbols creates the possibility of the creation of Bill of Materials with costs, finish, supplies etc. Now with the new modeling possibilities this workflow is even better. For subtractions you can now use symbols. If you use the hole tool in a symbol you can change every hole in just two steps. Vectorworks will update all subtractions where this symbol is used automaticlly 🎊🎊🎊 Attaci -

object attributes in a Data Tag

Bas Vellekoop replied to Bas Vellekoop's question in Wishlist - Feature and Content Requests

@The HammaIf you could vote this up with the arrow at the top of this page, that would be great!- 1 reply

-

- data tag

- attributes

-

(and 3 more)

Tagged with:

-

Color name of fill in a data tag

Bas Vellekoop replied to Bas Vellekoop's question in Troubleshooting

Done 🙂 , please vote up 🙂 -

object attributes in a Data Tag

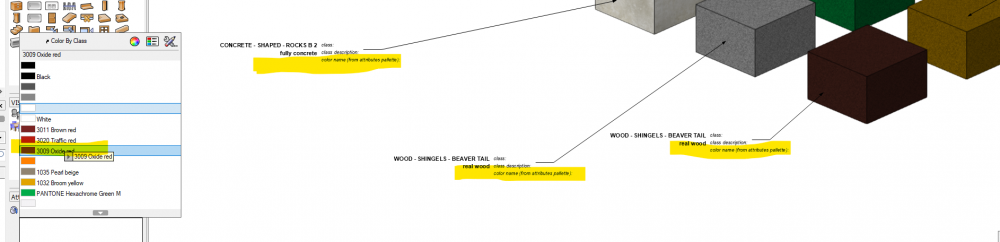

Bas Vellekoop posted a question in Wishlist - Feature and Content Requests

I would be a big time saver if it was possible to get the names of the object attributes in a data tag. A - The names of the fill styles: solid > color name hatch > hatch name pattern > pattern name and foreground and background color names tile > tile name gradient > gradient name image > image name when the fill style is set by class then then specified name in the class fill style B - The names of the pen styles: solid > color name pattern > pattern name and foreground and background color names line type > name of line type and name of color when the pen style is set by class then then specified name in the class pen style C - The line thickness D -The number of the marker Usercases: part B of this discussion: https://forum.vectorworks.net/index.php?/topic/79632-renderworks-textures-in-worksheet-name-of-color-in-a-data-tag/#comment-379286- 1 reply

-

- 3

-

-

- data tag

- attributes

-

(and 3 more)

Tagged with:

-

-

Renderworks textures in worksheet + name of color in a data tag

Bas Vellekoop replied to Bas Vellekoop's question in Troubleshooting

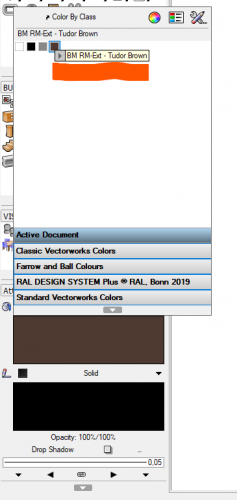

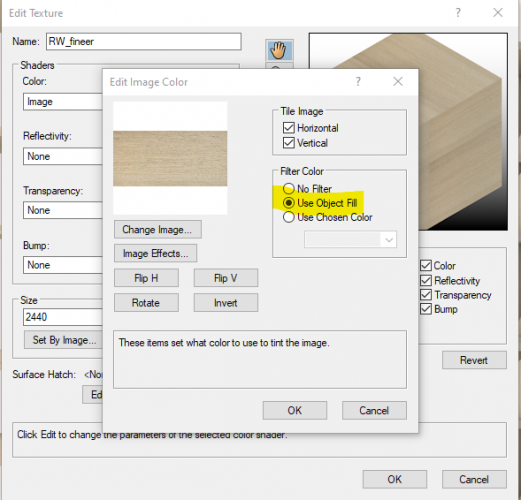

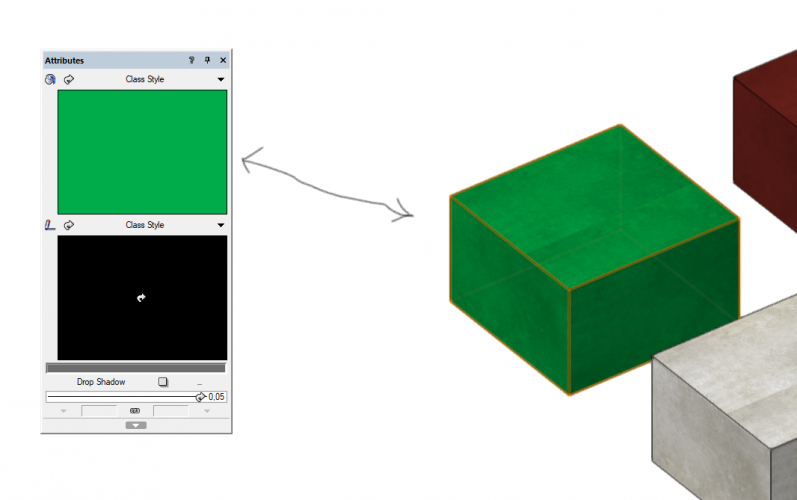

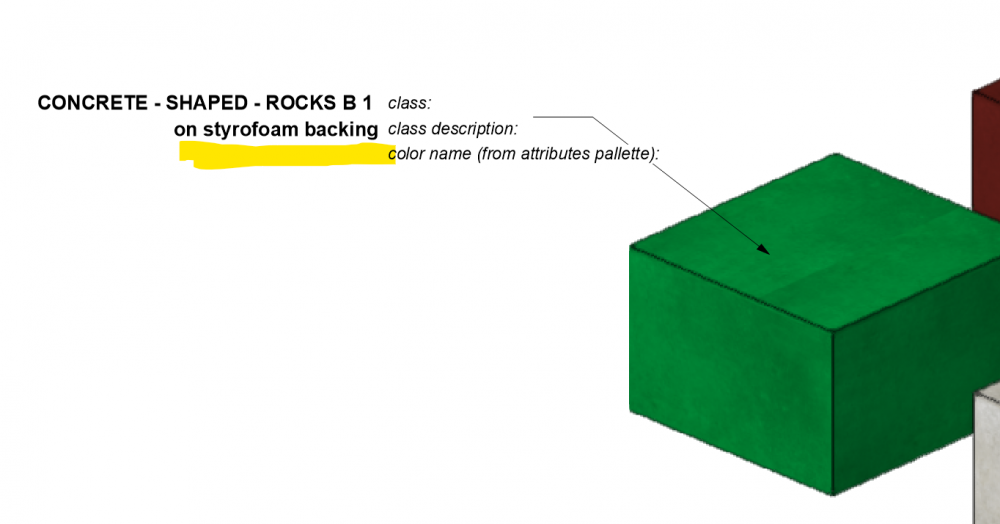

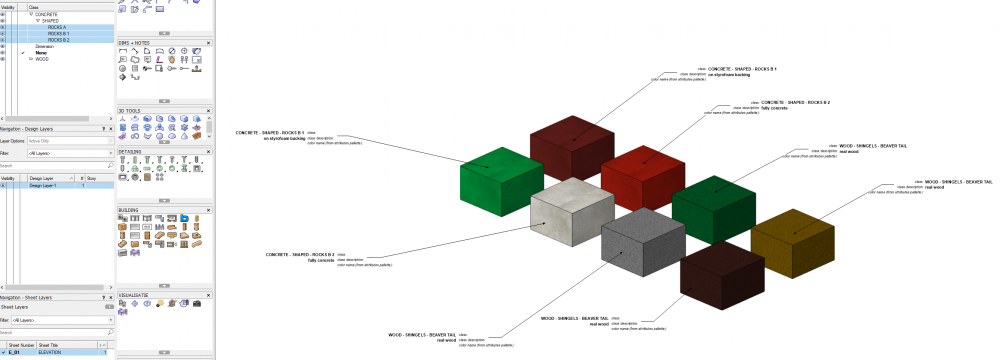

Besides the worksheet: Would you think it would be possible to get the color name (the color name that is available in the color palette) in the in a Data tag? tagging @Wes Gardner as well because he seems a master in data tags 🙂 The way I would like to use it: I have a big project with 10 different types of materials. These 10 materials can have all the colors available in the RAL color coding system. In order to prevent that i have to create all the classes for the 10 materials and the hundreds of different RAL-color I thought of setting the color of the material by the object fill in the attributes tablet. By doing it this way I can prevent the creations of hundreds of classes and can color object every object just the way I want. And if I can use a data tag to get the object fill / color name in a elevation i would be really happy 🙂 1: Set the color of textures by 'Object Fill': 2: Use the Attributes Pallete to override the standard color with a custom RAL-color 3: get the color name in a elevation with the use of a data tag: Would this be possible?- 2 replies

-

- renderworks

- worksheet

-

(and 1 more)

Tagged with:

-

Renderworks textures in worksheet + name of color in a data tag

Bas Vellekoop posted a question in Troubleshooting

Hi all, 2 questions: A: I`m wondering if it is possible to get Renderworks textures in an worksheet with an image of the texture. The idea is to create elevations with data tags which refer to a worksheet for the: material, texture, color, ... B: Is it possible to get the name of the chosen color fill in a data tag?- 2 replies

-

- renderworks

- worksheet

-

(and 1 more)

Tagged with:

.thumb.jpeg.48a6fdc44e48c98b8e1b507e86e57e95.jpeg)