-

Posts

1,331 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Stephan Moenninghoff

-

Short answer: yes. We did not forget about this. We have this firmly in our gunsights but there are some dependencies which we will need to resolve first. Thanks for your patience and sorry for the long wait!

-

I don't think we're doing anything here. It's entirely a macOS system thing.

- 99 replies

-

- 2

-

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with:

-

VW 24 menu and pallete font change

Stephan Moenninghoff replied to LeeElston's question in Troubleshooting

Hi @LeeElston text has indeed decreased in size somewhat. Sorry about the inconvenience this is causing you! I am sure you probably know this already but for what it's worth: you can incease text size in the Windows system setings, in case that is an option for you. -

Hmm, that's interesting. I just tried on Windows and I am seeing the snaps. Are you able to file a bug for this?

- 99 replies

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with:

-

Did you mean the scaling?

- 99 replies

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with:

-

Reports able to span 2 pages

Stephan Moenninghoff replied to Joe Golden ENT's question in Wishlist - Feature and Content Requests

I would love to understand your dream world a little better 🙂 . Could you post/DM with an example? -

Reports able to span 2 pages

Stephan Moenninghoff replied to Joe Golden ENT's question in Wishlist - Feature and Content Requests

I tried to reproduce this but I was not successful. In a Vectorworks worksheet, adjacent cells seem to share borders. You can turn the border on and off between any two cells from either of the two neighbouring cells. This is not the same as, for example, html, where each cell has its own border (and that comes with other quirks, like border-collapse properties etc.). If this does not work for you reliably, that sounds like an edge case or a bug. Do you have a sample file that demonstrates this? Could you share this file? Thanks! -

Reports able to span 2 pages

Stephan Moenninghoff replied to Joe Golden ENT's question in Wishlist - Feature and Content Requests

anything in particular you need? -

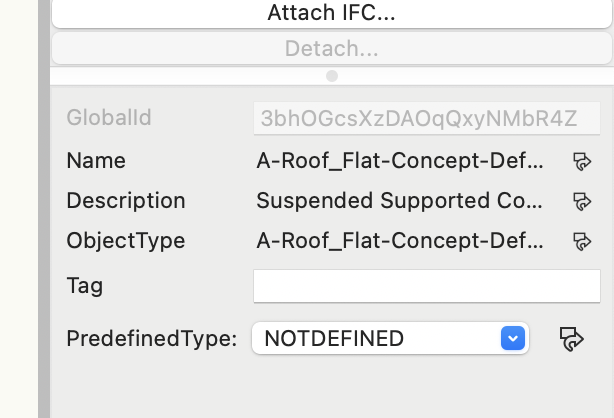

That's a bug. Thanks for letting us know! Could you share your screen resolution and UI scale preferences from your Windows settings as a screenshot here? I will try and reproduce it on my end to get it fixed.

- 99 replies

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with:

-

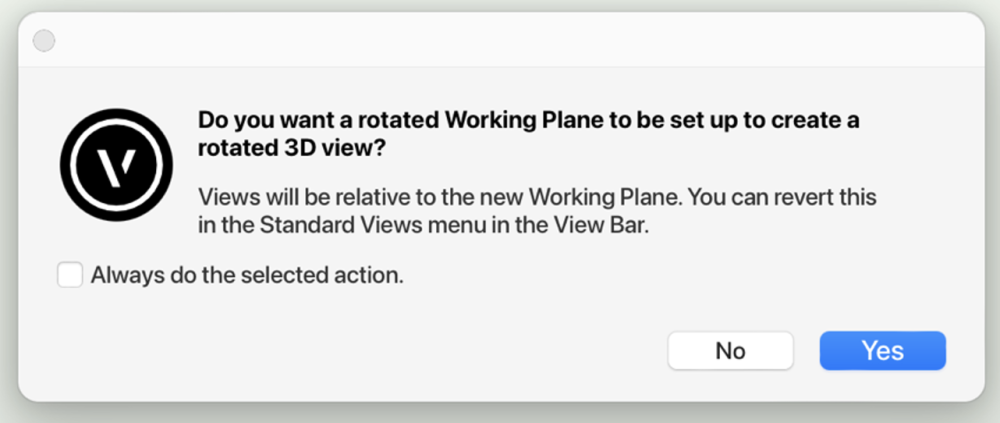

@Christiaan I have changed the wording of the alert for an upcoming task anyway because I found the same thing. Here is the proposed new alert. If this can be improved even more, I am sure we will be happy to do so.

-

3D dragger oversight is killing me

Stephan Moenninghoff replied to Kaare Baekgaard's question in Wishlist - Feature and Content Requests

Hey @Kaare Baekgaard I just tried and I cannot quite reproduce this. It seems to snap where it should. Can you attach your test file? -

Display the layer scale in text in View Bar compact mode?

Stephan Moenninghoff replied to GVMaEGjs's question in Troubleshooting

This is a Windows bug which we have logged to be fixed. Thanks for reporting!- 1 reply

-

- 1

-

-

Things I hate about 2024

Stephan Moenninghoff replied to Hamo's question in Wishlist - Feature and Content Requests

HI @Hamo Thanks for the suggestion. We are constantly collecting user feedback and will adapt any design choice we have made if we think that the majority of users will benefit. We have collected feedback on colour choices and icon styles (by way of a survey and focus group) and we now have two styles of icons - the mocochrome icons that use the user's accent colour when active and icons we use for tools and modes, which have the ability to use colour accents that are part of the icon itself. The interactive scaling is one of the latter, being a mode of the Selection tool. As you can see from the first mode ('Disabled Interactive Scaling Mode'), we can use a red accent here. Hope that makes sense. As @E|FA has pointed out, it is already a wishlist item. While we cannot guarantee if and when wishes are granted, we obviously prioritise wishes with a higher count of votes! -

Streamdeck integration.

Stephan Moenninghoff replied to Matster's question in Wishlist - Feature and Content Requests

There are several places where Icons are kept: Vectorworks.vwr Plugins Vectorscript tools and commands As of Vectorworks 2024, toolset icons are also stored in Vectorworks.vwr for easier access. Unfortunately, with Vectorscript icons, you cannot get to them from the plugins. I am attaching them here for you. VS.zip -

VW 2024 - VIEW BAR WIDTH (windows)

Stephan Moenninghoff replied to abartek's question in Troubleshooting

Hi @abartek thanks for reporting, this is a known issue which we are looking into.- 1 reply

-

- 1

-

-

Thank you! I will make sure it gets addressed.

-

Hi, @MogTheSmilingCat could you post a screenshot of your setup? Thanks!

-

VW2024 Dark Mode Custom Icons

Stephan Moenninghoff replied to Jesse Cogswell's topic in General Discussion

If SVGs are not displayed as you expect, there can be several reasons for it. I noticed you are using a non-uniform stroke. This might be one of them although I haven't tried. Here are the known issues: Patterns not supported Transformations not supported Non-scaling strokes not supported (just ignored. The icon still displays correctly) Nested clipping paths not supported. (You can use a clip path but you cannot clip it again, using another clip path on top of it). Using "_dark" as a suffix will use that resource for dark mode. Failing to supply it will use the light version for dark mode. You can still use PNG but SVG is preferred, as it stays sharp when the UI is scaled. Use a vector graphic app like Adobe Illustrator, Sketch or any other vector format authoring tool that lets you export SVG and you should be good. HTH -

Legibility Issues in v2024

Stephan Moenninghoff replied to alex_angusandmack's question in Troubleshooting

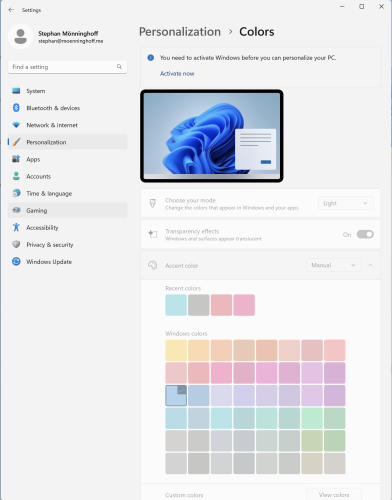

It uses the accent colour you have set up in your Windows Personalisation > Colors preferences. Can you check and let me know if a different colour helps you read these? -

As were many others. Very privileged to be part of a fantastic team here at Vectorworks!

- 99 replies

-

- 9

-

-

- vectorworks 2024

- new ui

-

(and 1 more)

Tagged with: