-

Posts

1,395 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Stephan Moenninghoff

-

-

2 hours ago, Owen Hankin said:

If so can you please let me know how you succeeded?

@Owen Hankin I have fished them out for you.

-

On 5/15/2024 at 8:08 AM, MogTheSmilingCat said:

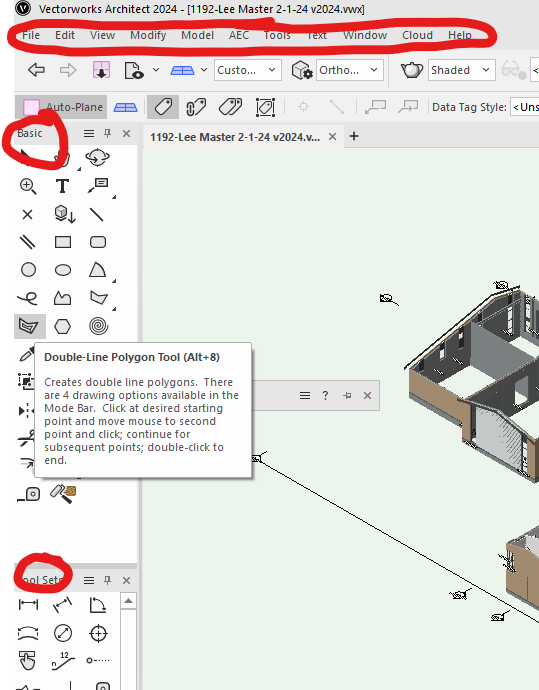

I hate to be that user who whines constantly about the same (apparently minor) thing but since VW2024 was so much about UI redesign, and we've got a UI that doesn't work well in its most useful configuration on the sort of screen most users will have... ...on *Update 5*. From what I've seen "compact" works perfectly on Mac but with Windows at 4k we still get all of the tools and menus crammed into the left hand side of the screen so drop-down box contents are unreadable. Is there a timeline...?

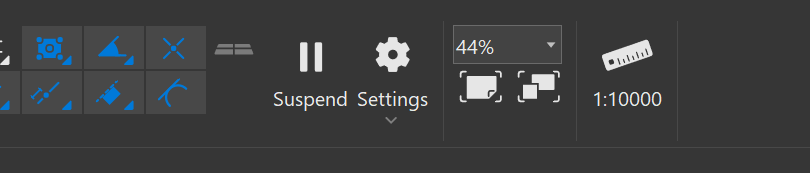

We have a fix in place for the compact View bar on Windows. This should be in the next beta. There is still a minor issue with it but I have it running here locally, and looking good.

-

1

1

-

-

@TurtleBuilds you might be better off just recreating your icon in Inkscape and exporting to SVG. If you're not bothered about aligning with the pixel grid, SVG is the better option as it wil support any sizes you end up with, due to UI scaling on Mac or desktop scaling on Windows. Unless this is purely utilitarian and you're not bothered about the look...

-

@TurtleBuilds I downloaded the 'Bahnschrift' font that you seem to be using and have converted it to vectors. Here is the result. (If you cannot upload certain file types, it helps to just zip them).

-

1

1

-

-

@TurtleBuilds you are using plain text in your SVGs. If you convert this text to vectors before you create the SVGs, you will be fine.

-

1

1

-

-

5 hours ago, Amarin said:

programm says that the object I chosed is invalid for creation of the section.

Is this already a section viewport you are trying to section? It needs to be a standard VP. Does that work?

-

- Popular Post

- Popular Post

-

I think it's quite possible with the tools we have in Vectorworks. I used the Deform tool with Taper Solid mode. Should be pretty close to what you need @Brandon Kleiman

-

4

4

-

1

1

-

-

- Popular Post

- Popular Post

On 3/12/2024 at 9:19 PM, MogTheSmilingCat said:Is there some weird problem us simple users don't understand

Short answer: yes. We did not forget about this. We have this firmly in our gunsights but there are some dependencies which we will need to resolve first. Thanks for your patience and sorry for the long wait!

-

7

7

-

5 hours ago, GatRed said:

I was wondering if it could always be displayed ?

(I’m using a 14" macbook pro M2).

Edit : It is a macOS option. I needed just to select “always display menu bar” in the macOS system settings app.

I don't think we're doing anything here. It's entirely a macOS system thing.

-

2

2

-

-

On 1/16/2024 at 3:24 PM, LeeElston said:

Can I change the style, size and fonts of text in the menus and palettes in vw 24. Text has shrunk and lost boldness making it much harder to read/see. Have you been taking lessons from graphic design companies putting cooking instructions on food packaging perhaps, and assuming everyone is young with 20/20 vision...

Hi @LeeElston text has indeed decreased in size somewhat. Sorry about the inconvenience this is causing you! I am sure you probably know this already but for what it's worth: you can incease text size in the Windows system setings, in case that is an option for you.

-

1

1

-

-

8 hours ago, Tom W. said:

@Stephan Moenninghoff I checked + the problem is still there regardless of the display settings.

Here is a test file Test file for Stephan_24-01-15.vwx

Thank you, I can see it now. Leave it with me, I will create a bug for it.

-

1

1

-

-

5 hours ago, EAlexander said:

@Stephan Moenninghoff Hi! No, I did mean snapping. Two users have suggested unpinning snapping from the view bar and they have it returning to the lower right corner of the viewport window like previous versions. I cannot replicate that - if I unpin, snapping menu simply goes away all together. I wondered if that was because I was on windows and they are on Mac, but I realize that is an assumption.

Hmm, that's interesting. I just tried on Windows and I am seeing the snaps.

Are you able to file a bug for this?

-

On 1/10/2024 at 7:28 PM, EAlexander said:

I assume the snapping thing is a mac vs windows thing as both people suggesting it are on Mac and I'm on Windows.

Did you mean the scaling?

-

13 minutes ago, Tom W. said:

Hopefully someone from VW will pick this up to save me filing a bug report...

I'm not seeing this with the latest beta. Do you have a sample file showing the issue?

-

On 12/15/2023 at 5:37 PM, spettitt said:

In a dream world, database rows would work more like a proper database reporting engine:

- Group headers (large flat table splits in to multiple table chunks based on the data - i.e. Group By Field x)

- Hierarchical group headers - group on X field, then group on X field.

I would love to understand your dream world a little better 🙂 . Could you post/DM with an example?

-

On 12/16/2023 at 9:47 AM, GatRed said:

I have difficulties to set borders : if I want to remove the down border of a cell, sometimes it does not work. I have to select the cell below and remove the up border.

I tried to reproduce this but I was not successful. In a Vectorworks worksheet, adjacent cells seem to share borders. You can turn the border on and off between any two cells from either of the two neighbouring cells. This is not the same as, for example, html, where each cell has its own border (and that comes with other quirks, like border-collapse properties etc.).

If this does not work for you reliably, that sounds like an edge case or a bug. Do you have a sample file that demonstrates this? Could you share this file?

Thanks!

-

7 hours ago, _James said:

how difficult they are to format.

anything in particular you need?

-

On 11/30/2023 at 3:21 PM, Philip Humphrey said:

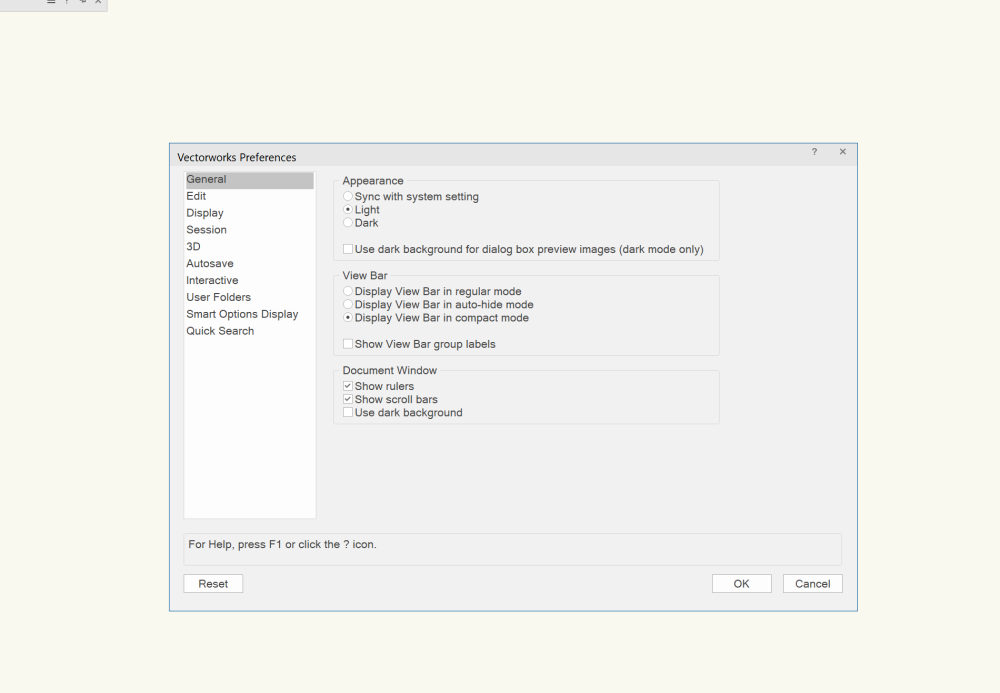

That's a bug. Thanks for letting us know! Could you share your screen resolution and UI scale preferences from your Windows settings as a screenshot here? I will try and reproduce it on my end to get it fixed.

-

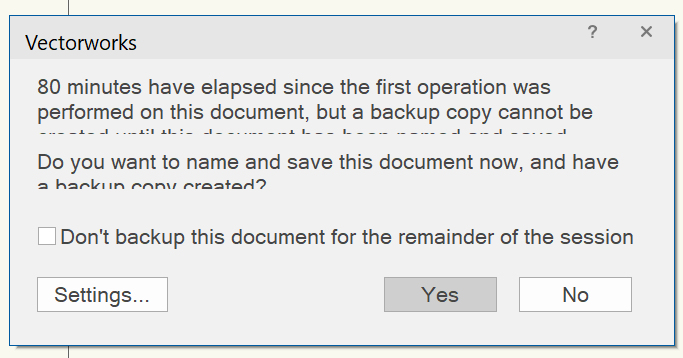

@Christiaan I have changed the wording of the alert for an upcoming task anyway because I found the same thing. Here is the proposed new alert. If this can be improved even more, I am sure we will be happy to do so.

-

2

2

-

1

1

-

-

Hey @Kaare Baekgaard I just tried and I cannot quite reproduce this. It seems to snap where it should. Can you attach your test file?

-

4 hours ago, GVMaEGjs said:

This is a Windows bug which we have logged to be fixed. Thanks for reporting!

-

1

1

-

-

- Popular Post

- Popular Post

14 hours ago, Hamo said:'Interactive Scaling' and 'Marquee Selection' need to be green / black for on / off like the 'Snapping' tools.

HI @Hamo Thanks for the suggestion. We are constantly collecting user feedback and will adapt any design choice we have made if we think that the majority of users will benefit. We have collected feedback on colour choices and icon styles (by way of a survey and focus group) and we now have two styles of icons - the mocochrome icons that use the user's accent colour when active and icons we use for tools and modes, which have the ability to use colour accents that are part of the icon itself. The interactive scaling is one of the latter, being a mode of the Selection tool. As you can see from the first mode ('Disabled Interactive Scaling Mode'), we can use a red accent here.

Hope that makes sense.

14 hours ago, Hamo said:Need to be able to manage the positions of the 'View Bar Groups'.

As @E|FA has pointed out, it is already a wishlist item. While we cannot guarantee if and when wishes are granted, we obviously prioritise wishes with a higher count of votes!

-

5

5

-

54 minutes ago, E|FA said:

Only a partial set. A bunch must be hiding somewhere.

There are several places where Icons are kept:

- Vectorworks.vwr

- Plugins

- Vectorscript tools and commands

As of Vectorworks 2024, toolset icons are also stored in Vectorworks.vwr for easier access.

Unfortunately, with Vectorscript icons, you cannot get to them from the plugins. I am attaching them here for you.

-

3

3

Placing Hide Selected Objects in object context menu does not work?

in Troubleshooting

Posted

Are you running antivirus software? This sounds like something is blocking parts of Vectorworks.