Conrad Preen

Vectorworks, Inc Employee-

Posts

1,023 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Conrad Preen

-

Extra steps adding up... Ok, you just persuaded me 🙂 and yes point taken about the full width, half width thing. Though in these cases there is usually a rack shelf that can be effectively modeled as a rack frame. Conrad

-

Hi Jeff, I think the first question is "how big a deal is this?". One simple workaround would be to set the number of slots to 1 and leave a gap to the right. Wonder if the Use Symbol option would work? If you created a symbol for these particular cards? Of course we could add an extra parameter Number of Slots Horizontally. But is this going to improve ConnectCAD? Just a few random thoughts... Conrad

-

Hi Christian Yep this is another of those curve balls the industry throws at us. Haven't an immediate answer for you but I think we ought to hook up on Zoom sometime this week. I'm in GMT +2 so why not send me a PM with a couple of slots where you are free. Conrad

-

So, yes I can see the issue there even in our latest research build. Let me ask you to play software designer for a moment. What do you think the rules should be for sizing and displaying Name and Make-Model? At the moment we fit the Name into the top 1U of rack-mount equipment. That seems to give a nice consistent size for Name. Make-Model is sized to go into 1U like this: Make Model Right justified if the Name is Left or Center, left justified if the Name is Right. The problems begin around 1U high half-rack size. We can't shrink text indefinitely it becomes unreadable. Should we simply drop the Make-Model in that case? What do you think? Conrad

-

Hi Christian, Thanks for clarifying. The idea with this is that the Equipment Item should automatically adjust font size to fit the box and maintain readability. Once the Make Model text gets too small it should automatically be dropped leaving only the Name. I think we have a case here that defeated us. Is this in the file you sent me? Conrad

-

Brandon, Regarding content, something you have to appreciate is that we as Vectorworks can't simply scrape stuff off the internet and sell it as part of our product. Other people have worked to create that material and will correctly demand a share of what we gain from using it. So, when we release content as part of Vectorworks we have to secure the agreement of each and every provider. Plus checking the validity of the info, plus getting it all into a unified format etc. and then setting up a maintenance schedule to re-check every item to follow product changes. It is not a trivial undertaking. Stardraw have been doing this for years and as you say, they make mistakes. Don't get me wrong. I really value the debate here and I listen carefully to the opinions expressed. But debate is not one-sided and I have as much right to my opinion as you have to yours. Here at Vectorworks we are in the business of making promises that we will deliver, so on occasion I will politely disagree. If you are not satisfied with the substance of my response then by all means look elsewhere. There are plenty of companies out there that will say anything to retain your custom. Kind regards Conrad

-

Current Layer Reports not duplicating properly in v2020

Conrad Preen replied to Kevin Krautle's topic in ConnectCAD

Hi Kevin, Thanks. I will take a look at that. Maybe something that slipped through the cracks in the conversion to SDK. Let you know. Conrad -

Hi Christian, Select the Equipment Items to change and use the Font > Size menu to adjust. You'll probably have to set a really small size because of the layer scaling. Conrad

-

It is fixed in ConnectCAD 2021. Release coming soon. Conrad

-

I don't know what "snarky" means I'm afraid. I struggle to see anything in my reply that could cause offence. By all means draw my attention to whatever you find "snarky". We have a decades-long track record of happy customers. But it's a fact of life that we won't be able to please everyone. We will do our best though. Best regards Conrad

-

Hi Brandon, I'm not the admin so I can't move threads around. So we will stay here. Our user base is involved in a broad range of design activities. With all respect, I think I am better informed about that. Some fit your profile as a Spotlight-intensive user of ConnectCAD but others never use Spotlight tools at all. Regarding your personal expectations, what you seem to be asking for is a ConnectCAD more customised to your workflow. This is something you can already do yourself and many users add custom fields to our objects to support the various specific device families you mention. We are also watching carefully to see what customisations might become a part of the standard product. But we want ONE standard product - supporting a huge number of variants to satisfy different users is the road to destruction. So now onto Content. With the acquisition by Vectorworks the ConnectCAD team has increased enormously. We are working hard to take advantage of these new riches. It won't be all done in a day. And it will never finish either. Of course I agree that more 3D content would be great. But I suspect you haven't looked into what's already available and usable. Check out the Did you know thread in the ConnectCAD section for nuggets of info. You've already hit the nail on the head with Stardraw. They have these huge libraries that they brag about, but as you say they are not well-maintained. That's the problem with libraries. Nobody can keep up to date. We can't either. So our solution is to give you the designer the best tools we can and full control over your drawings. We're on your side. I spent 25 years of my life designing systems, if there's a faster more reliable way I'll be the first to implement it. Vectorworks is unique. I don't know any other software company where you can talk directly with the manager of a product and engage in this kind of debate. I've already noted your rack layout to schematic workflow ( the reverse of the current one ). That's intriguing. I'll look into it. Keep in touch Conrad

-

Hi Brandon, Ideally this topic belongs in its own thread. I know that sounds pedantic but when you come to search the forum for that nugget of info you remember reading, it's way easier if the title matches the content. So why is ConnectCAD not like StarDraw? That's a huge question. Why should it be? If it was the same then StarDraw might as well not exist. Over the many years of ConnectCAD's existence I've often been asked these kind of questions. There is room in the world for many different approaches. For sure we can look at other products and see what features might be useful to add but there's no point in slavishly copying others. You moved from StarDraw to ConnectCAD. Why? Libraries have never been a big part of ConnectCAD because they go stale very quickly. Who underwrites the accuracy of StarDraw's libraries? What does the small print say? Here at Vectorworks and previously ConnectCAD we have taken the view that it's better to provide tools for fast and easy device creation. It's a different and perfectly valid approach that has worked for the past 20 years. If there is a consistent demand for ready-made premium content then we will review and respond accordingly. We are always working to improve our software and we do value your comments and the debate here on this forum. Regards Conrad Preen ConnectCAD Lead

-

Hi Christian, Can you send me PM a file that shows this misbehaviour? Sounds like a translation issue to me. Regarding genlock and network ports on frames, this is what we were discussing above. You create a device on your schematic with the same name as the rack frame and add the genlock and network sockets to it. Best Conrad

-

That will work fine - the device just won't get location info. That's what we're fixing now.

-

Hi Joergen Yes you can make power diagrams with ConnectCAD and many people do. In fact ConnectCAD has been used to design compressed air and water systems too. You'll probably want to expand the standard signal and connector types to suit your needs but this is easy. Does it work with Spotlight? I guess yes assuming the Spotlight info is exposed as record fields. The very specific example you give is a bit beyond my knowledge of Spotlight but @JimWoodward could probably advise. Best Conrad

- 1 reply

-

- 1

-

-

Hi Leigh Sounds like I should take a look at those text files. Could you send them to me as a PM? Conrad

-

Hey Ryan, Glad to help. That's a darn good question you raise. In the old Vectorscript version you used to be able to create a device with the same name as the rack frame and it would "know" where is was (room, rack, rackU). What I'm seeing is that in our current version now upgraded to SDK we have lost this. So thanks for asking - I'll have that put back right away it shouldn't be a huge challenge. Anyway the workflow is just create a device on your schematic for the frame and add the power sockets. Conrad

-

Why? Because haven't added it to your ConnectCAD workspace! One of the great things about Vectorworks is that you can make the workspace exactly the way you want it. Check out the Vectorworks Help on the Workspace Editor. It's easy to add any command from Spotlight or other modules to the ConnectCAD workspace, or set up your own keyboard shortcuts... Look into it. You'll never look back. Conrad

-

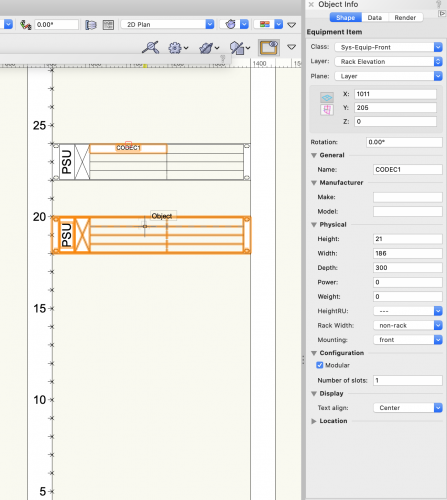

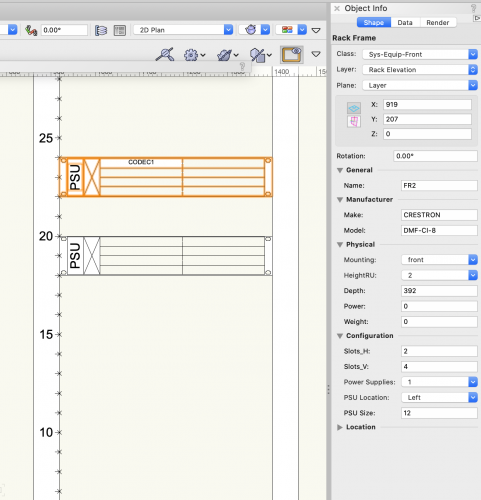

Hey Ryan This is simpler than it seems. Get the Rack Frame tool (Layout tool set) and click in the drawing to create a frame. Head over to the Object Info Palette and configure it. For the DMF-CI-8 you would set the frame to be 2U with 2 slots horizontally and 4 slots vertically. For the codec card just set the device as modular and when you create equipment using Update Rack Elevation, the corresponding Equipment Item will be set modular - you can just drag and drop it into the frame slots and it will size to fit (you may want to set the text size smaller - Text menu). Here's two screenshots to get you on your way. Hope that helps Conrad

-

Hello @HSTEW, Unless you absolutely need to have stuff in more than one file, I would recommend that you keep everything in one file in the current version. If you need simultaneous multi-user access to the file then use Vectorworks Project Sharing. Project Sharing is already working reasonably well in ConnectCAD 2020 and is fully tested in ConnectCAD 2021. Links between files will be officially deprecated as of 2021. Hope that helps, Conrad

-

Dear ddmbrandon, ConnectCAD has a command Make Cable Labels which creates a worksheet containing the cable numbers and other circuit parameters you may wish to include. What it does not do is format the sheet ready for printing. The reason for this is that we don't have such precise dimensional control over column width. But in any case, why would you tie up a CAD workstation printing labels when you can export to Excel and do it all on a cheaper spare PC. That's also the reason why I don't see much point in interfacing to special label printers when they all have perfectly good software that can print from a spreadsheet. Tel me a bit more about what's puzzling you and I'll try to explain. Conrad

-

Hi Chris, There isn't really a way to assign a keystroke to the double-click action of a tool. However, what I can suggest is that you check out the "multi' mode of the Connect Tool. It let's you connect bunches of sockets at once, and it is quite smart about signal types. Try it out going from device label to device label, the try what happens if go from socket to socket. It filters the available signal types accordingly and makes some fairly sensible choices :-). Experiment a little and you'll see what I mean. I have the feeling that the tools are there already, you just need to tweak the way you use them. Best Conrad

-

Hi CHA, double-click is slower? Well that's a revelation! It's not straightforward to assign a keystroke to this but I will investigate what is possible... Conrad