-

Posts

445 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Wesley Burrows

-

Service Pack 2 for Vectorworks 2018 Released

Wesley Burrows replied to PVA - Admin's topic in News You Need

-

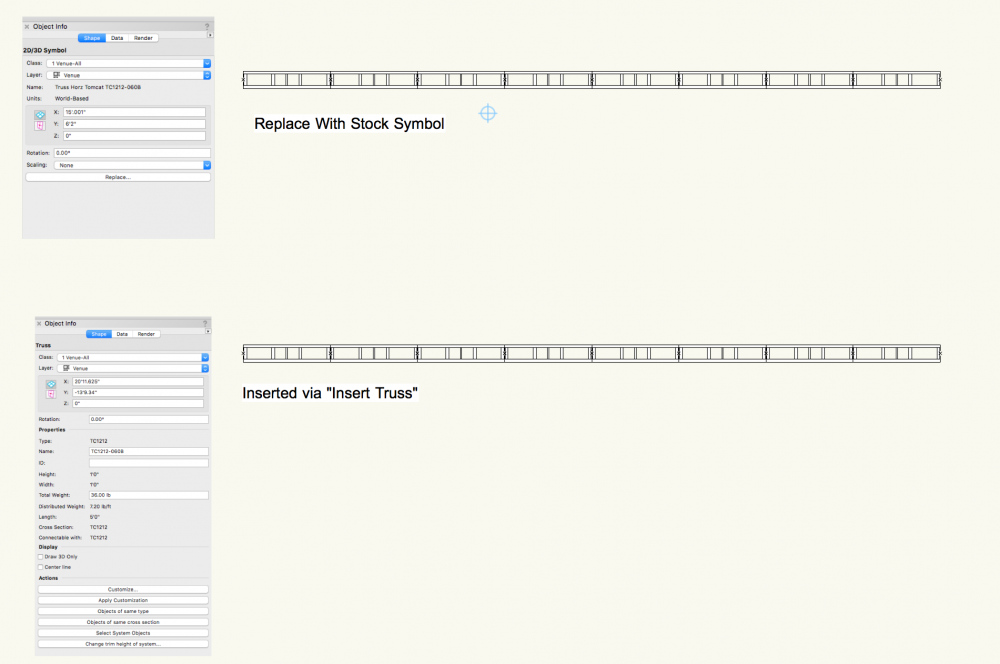

If you use the truss PIO to rough in your design, (maybe you're not sure what truss you'll be using yet) but you finally solidify that and want to replace your PIO with stock symbols, great. How come when you do this, the replaced pieces of stock symbols do not auto connect as a system as they would if you redrew the whole thing via the insert truss tool? I'm using the same symbols for replace with stock symbols as I am for the insert truss symbol. It seems to me like it should auto-connect. Am I missing something? Was this intentional, overlooked, or deemed unnecessary? V

-

Spotlight - Align Distribute Tool Crashes 2018 SP1 & SP2

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Update, this bug still exists in SP2.- 10 replies

-

- spotlight

- align and distribute items

-

(and 2 more)

Tagged with:

-

VW2018 Lighting Device to Position Snapping (Bug Test)

Wesley Burrows replied to James Russell's question in Troubleshooting

I tested all of the above and confirm they seem to be solved in SP2- 4 replies

-

- lighting device

- lighting position

-

(and 2 more)

Tagged with:

-

Currently the video screen is the only device that "attaches" to a hanging position if you attached it as a load, they don't attach separately. I have been face first into Braceworks the last 2 weeks or so, using it on a pretty size-able show, so I can try and help. The PJ load is calculated as part of the truss it is under (hanging position or not) if it is within the Braceworks user preferences tolerances of proximity to the supporting truss. If you have the PJ lower than the threshold under the truss it will not calculate it. Because you can't attach the screen and PJ separately, in that case I just add a point load to the truss with the PJ's weight and use that for Braceworks calculations instead of the actual PJ symbol. If that helps. I haven't found much in the way of tutorials, though I was at a breakout session at Vectorworks Design Summit with the guy who created it, so, of course, that helped.

-

The times I've needed to do this I either done it via Cinema 4D exporting the model and replacing the screen material with video, OR rendering a still in VW replacing the screen with green and keying it out in After Effects. It would be great to able to do that in VW, Along these lines I wish you could link a camera to a texture to have IMAG on a screen without doing a separate render for that.

-

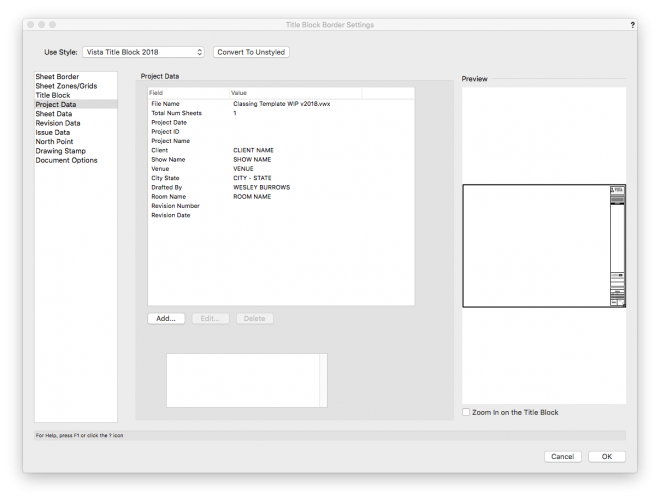

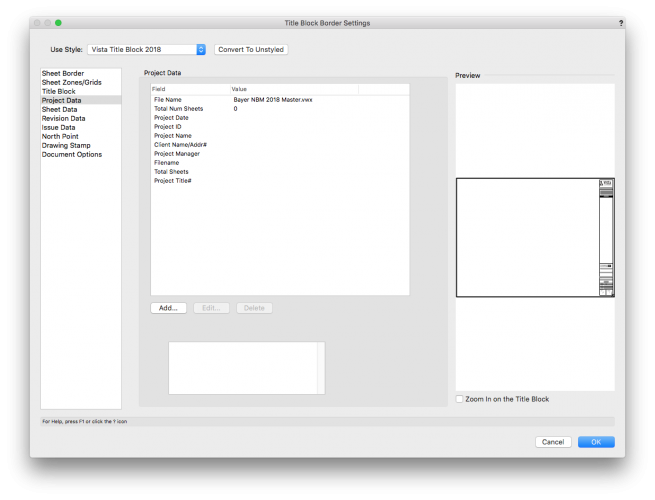

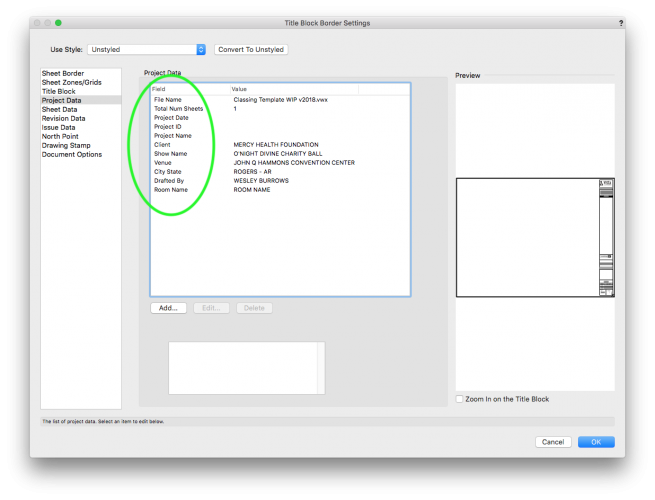

I have a 2018 sheet border/title block design that I made in my template file. I want to use this in an existing file. When I tried copying the sheet border from my template file and pasting it in place in my existing drawing, all of the data fields are reset to default, How do I correct this? I've tried purging sheet border special records, reseting plugin objects. Template File: Paste from Template File:

-

VW2018 Lighting Device to Position Snapping (Bug Test)

Wesley Burrows replied to James Russell's question in Troubleshooting

@JimW this might get a bit more response in the Spotlight section, or perhaps Troubleshooting. @BrandonSPPdo you know if any of the above has been addressed in the forthcoming SP2? -W- 4 replies

-

- lighting device

- lighting position

-

(and 2 more)

Tagged with:

-

VW2018 Lighting Device to Position Snapping (Bug Test)

Wesley Burrows replied to James Russell's question in Troubleshooting

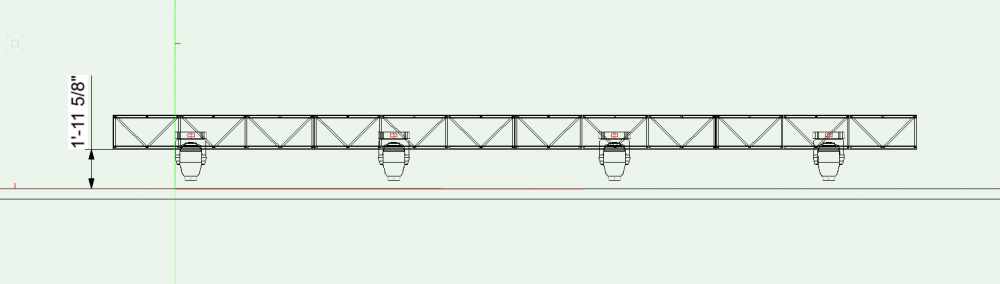

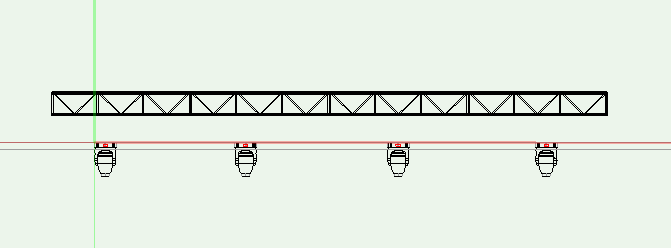

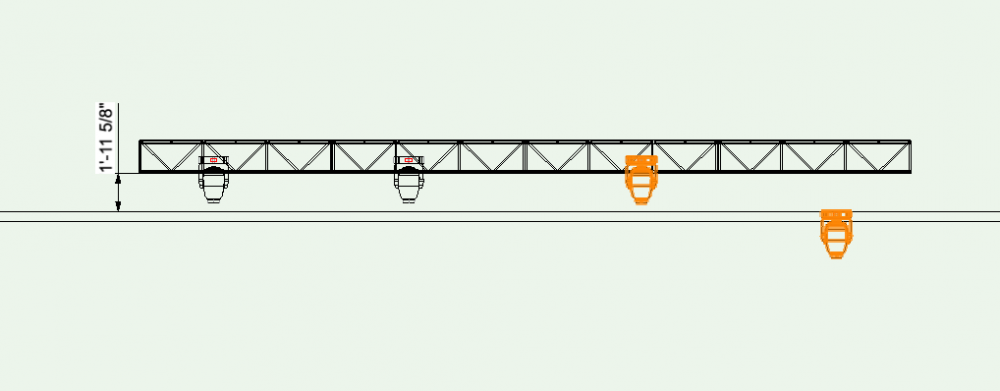

Part One Result (with Truss PIO) x Part Two Result (with Truss PIO) Both ended up the same for me. (wrong, because of moving lights inside the truss) but attached. Unless you tried the fun party trick of selecting all of that position and moving it to a new design layer. Then you get this fanciness: Or if you delete the right two fixtures from the original and mirror the left two across the center line, then you get this: There are lots of issues with the 2018 (SP1 at the moment) hanging position. So I don't doubt you are getting strange results.- 4 replies

-

- lighting device

- lighting position

-

(and 2 more)

Tagged with:

-

Can we please get the ability to drag and reorder these data fields on the project data and sheet data fields without deleting and recreating.

- 13 replies

-

- 1

-

-

- 2018 sp1

- improvement

-

(and 1 more)

Tagged with:

-

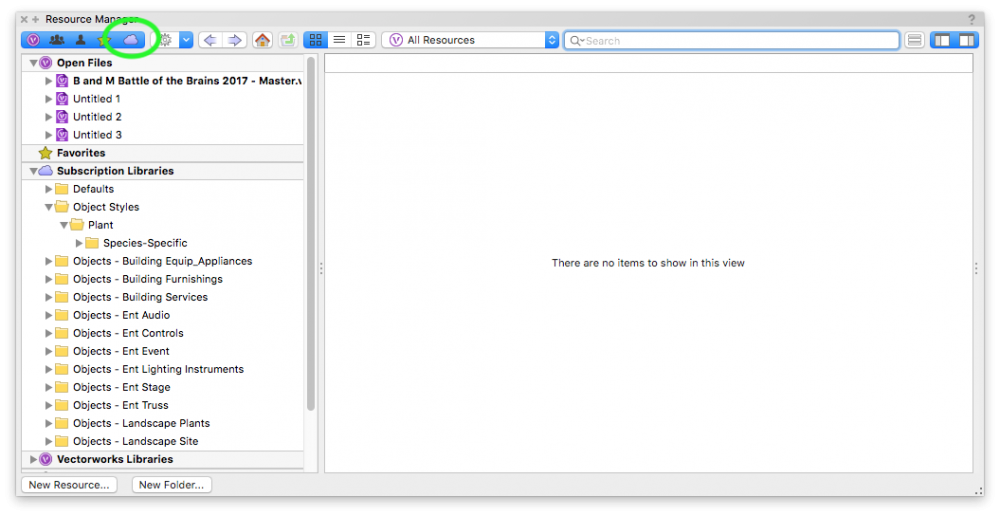

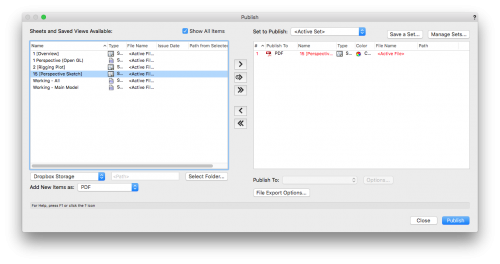

I'm trying to do some VW cloud publishing, I managed to get it working with the default Cloud Services Folder, but when I tried Dropbox it I get this,: The resultant PDF is like 834bytes (Blank). The VWX is sync'd in my company's dropbox folder(s) where it lives, and I also exported the file to the same folder. I have given cloud services permission for full Dropbox integration. I suspect that the way I use aliases might have something to do with it. Basically we use dropbox as a company, but the folder organization that works for the majority, sucks for me and there is too much time navigating, not enough time doing. So I do something like below: My Company wants: Dropbox > Current > Client > Show Name > Layouts and Renders (there are other folders, but this is only one I care about) What I want to see: Dropbox > Working Plots which shows a list of all the current shows by show name that points directly to the respective "Layout and Renders" folder of each. I accomplish this via some applescripting and aliases. However when I added full dropbox integration to Vectorworks Cloud Services my dropbox then shows: It seems to just hang while syncing remaining files, which based on the sync icons in my Working Plots directory, it has X's at all of the aliases like that's causing it, or if VW cloud services is in some sort of endless loop trying to index my dropbox account. I'm not sure. But it works fine without the integration. Do aliases break the integration? Can anyone offer any help?

-

- cloud services

- dropbox

-

(and 1 more)

Tagged with:

-

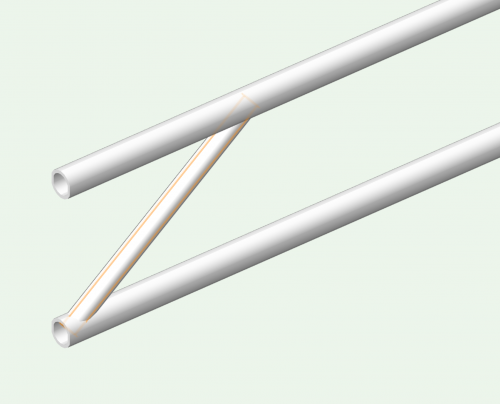

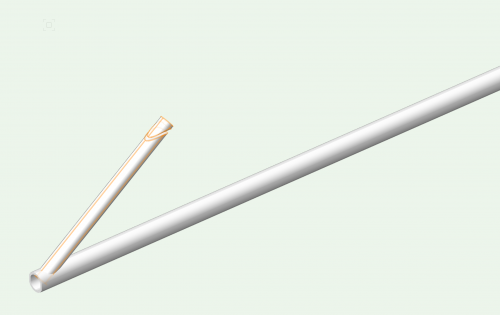

Drawing Truss Lacing - Trimming/Contouring Pipes

Wesley Burrows replied to Wesley Burrows's topic in Solids Modeling

Thanks Pat! I thought that might be the case. Your points are all very valid. More for my curiosity I guess and problem solving. Though as you state, for 99% of people's use cases, it's likely not a problem to really bother solving. -

If I were trying to model the side lacing on a truss. How would I get the selected extrude along a path to trim it's ends contoured to the top and bottom extruded circles? Or am I approaching this the wrong way? I tried subtract solids, but it doesn't remove the end, I assume because the top and bottom pipe have a hole through them. I'm sure I'm just being an idiot. What is the smart way to do this?

-

I agree a highlight toggle like that of the truss tool would be useful.

-

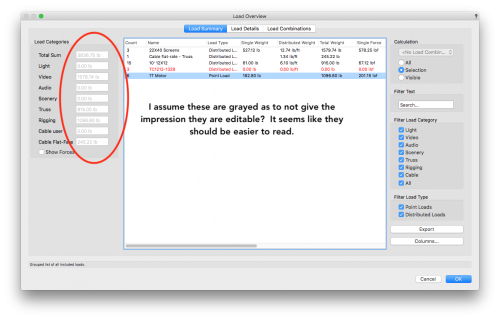

Are the sub-totals on this screen gray so not to appear user editable? Can they be more contrasty so they are a bit easier to read?

-

This is brilliant! I would contribute to a go fund me to pay this persons salary. As someone who clicks all day, 5 (or more) days a week, (90% of the time in Vectorworks) my clicks are valuable to me, I fight with carpal tunnel regularly and there are only so many clicks I have before my clicking finger just gives up. Please don't make me spend them unnecessarily. It gets to be infuriating when my finger/hand is giving up and I'm clicking when a TAB, ENTER, ARROWS etc will do! PLEASE. I'm only half-kidding. I swear everyday I'm closing in on my clicking fingers MTBF. (I also own the most ergonomical mouse I could find, an Evoluent Vertical Mouse, and it has been a big help, but still)

- 88 replies

-

- titleblock

- 2018

-

(and 1 more)

Tagged with:

-

Spotlight - Hoist Tool Improvements

Wesley Burrows posted a question in Wishlist - Feature and Content Requests

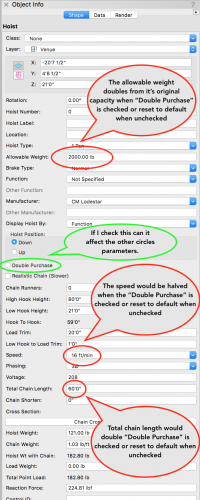

I'd like to propose that when you toggle the double purchase (sidebar, I've always heard this as called double reeved when referring to motors, and double-purchase for fly rail systems, maybe it's a US thing?) option in the hoist tool the diagramed changes happen. Basically: When the toggle is ON: The max allowable weight of the the selected hoist doubles from it it's default capacity The speed in feet per minute is halved (though this is't a big deal, but it might be useful) The total chain length get's doubled from it's default or current value. When the toggle is OFF: The max allowable weight returns to the defined max of the selected symbol. The speed in feet per minuted is doubled (once again, not a big deal) The total chain length get halved from it's current value. After inserting a bunch of 1/4T's that are double reeved (double purchased) for a ballroom show, I have to update them all the time to have their max allowable weight be 1000#'s. I've found every time I insert one it resets to the default max of 500#. Option + Dragging won't work half the time cause the motor won't attach to positions when I do it that way. The eye dropper tool also dosen't seem to want to grab the max weight as part of the plugin parameters. The tool WILL however remember the double purchase toggle, so It would be great if it could adjust the base values accordingly with it on. After all this is how motors generally work in the real world. It would make the tool more useable especially in conjunction with Braceworks. I am open to further thoughts/discussion. Just some observations of the tool use while diving face first into Braceworks.-

- 1

-

-

- spotlight

- braceworks

-

(and 2 more)

Tagged with:

-

Hanging Positions don't assign Heights anymore.

Wesley Burrows replied to markdd's question in Troubleshooting

Here's hoping! -

Hanging Positions don't assign Heights anymore.

Wesley Burrows replied to markdd's question in Troubleshooting

No, brand new layers with no height. On one hand Braceworks has saved me a bunch of time, on the other, I'm beating my head against the wall with some otherwise simple tasks. -

Hanging Positions don't assign Heights anymore.

Wesley Burrows replied to markdd's question in Troubleshooting

I am on SP1 and have run in to this too. The Z height changing when reassigning layers is driving me insane. I have had it happen with lights and video walls so far. -

Braceworks Cross Section info From Manufacturers

Wesley Burrows replied to Wesley Burrows's topic in Braceworks

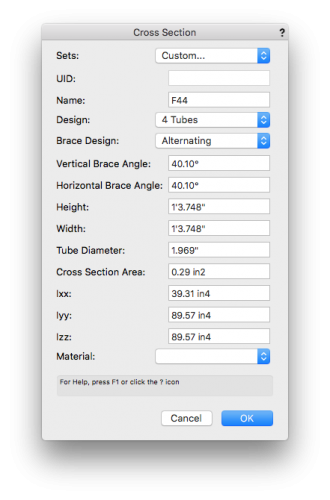

For those those of us that also have some quantities of slightly less mainstream manufacturers. (Applied Electronics in my case) Where they aren't in the library at all, what would be the appropriate method to try and obtain that info? -

For manufacturers that wouldn't (or just haven't) provided the truss cross-section information to be included in the Vectorworks truss library. (Ugh) What is the right information to ask for from them, on an individual request basis? I think I remember it primarily being the lxx, lyy, and lzz. But I can't remember the exact terminology. Or should I just send the screen shot and ask them to be so kind as to provide the asked info? Edited to add: Tomcat responded to me and they aren't providing that information at this time, but their engineers have a meeting with Vectorworks after LDI. Fingers crossed :-)