Samuel Derenboim

Member-

Posts

483 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Samuel Derenboim

-

ISO 19650 Compliance - Revisioning

Samuel Derenboim replied to shorter's question in Wishlist - Feature and Content Requests

Generally in our company we use the sheet number as the initial page number i.e. Z001 A002 and revision numbers for post amendments - i.e. Z001 - (rev .01) This then can be modified in a worksheet that references the sheet name, number and revision - and can be edited dynamically -

Hardscapes do not render tiles in cross section

Samuel Derenboim posted a question in Troubleshooting

Can someone please verify - hardscapes do not support tiling in cross section? FYI I am using hardscapes in completely unique ways, however, on screenshot 1, the hardscape does not show tiles, but it does show hatches. Could someone confirm please? -

Door Tags are not in sequence in Worksheet

Samuel Derenboim replied to Ramon PG's topic in Architecture

VW does sequential sorting, so depending on what you sorted first, it will use that as the primary sorting element. Unsort everything first, and then sort column a first, then column b. I think that should be able to work. -

@GatRed Ah i didn't notice your last post. Congrats!

-

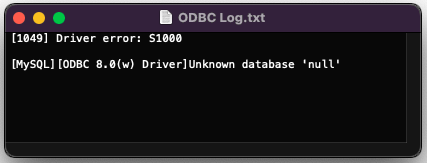

@GatRed Yea, I understand the frustration. Took me a bit of time to do it as well. The good thing is once you get it working, its a breeze after that. When you go into the iODBC driver options, is this what you see? Notice I have to pick a database name/table in order for me to access it. Also, do you have the tabs all the way at the bottom? (if not, click on the details button bottom left hand corner). Hopefully it's just your settings as iodbc connects just fine from the driver Also the error below i think means you didn't pick the database table to connect to. make sure they match names. I have a database table with the name window_catalog in it, and test your connection before closing as well. Maybe its just the table designation that's throwing it off.

-

what version of mysql is it? can you post the docker / docker compose script? Also, try playing with the settings of the mysql driver. They also have 2 drivers, 1 uni and 1 ansi. maybe the ansi one works better on mac? Also, as an experiment, try recreating another connection via iodbc driver. There are also certain options you can use in the connection, maybe there is something in the settings that is in conflict with VW

-

it seems mariadb is not supported https://app-help.vectorworks.net/2023/eng/VW2023_Guide/Database/ODBC_driver_information.htm https://mariushosting.com/how-to-install-mysql-on-your-synology-nas/ Just FYI, I started out with a Synology NAS as well, but after a certain point it became too limited for hosting options, which is why I learned to use Docker.

-

can you show a screenshot of the error? It could possibly be the connection to MariaDB is not compatible with ODBC driver. If you want to use mariadb, try installing this driver. Mariadb was originally forked from Mysql, but i do not think they are the same. That could be another cause. https://mariadb.com/kb/en/mariadb-connector-odbc/

-

Your dsn appears to be Gramysql not odbc 8.0 there error show that it cannot find the driver name. They have to match. Additionally since you populated it in your iodbx driver, it might not be necessary to enter it into vw. Repopulate available databases in the first table where you load the database. Gramysql should be there.

-

@GatRed Are you running a mysql server? does it work via phpmyadmin? or similar? Have you created a database table inside the server? did you install the latest odbc driver for mac? Can you show us a screenshot of your DB connector window? FYI https://dev.mysql.com/downloads/connector/odbc/ Use the driver to connect to your database first. If it connects, you will be able to use it in VW. See above posts for referencing db info into VW Also, once you confirm connection via outside source (i.e. self hosted http access), try this connection (it should work the same, system independent) DSN=MYSQL_Uni;UID=sa;PWD=password; DSN : Driver name for mysql after you install it UID : Username (often its root, but if you create a separate user to access the db table, you can use that) PWD=password for username to access database table

-

I agree, Graphic legend drawings do not export to dwg. Did an experiment on both exporting sheet layer to model layer and regular export with separate sheet layer views.

-

Currently I am in the process of recomputing many of the k-values for the materials that come shipped with VW there are quite a few things missing when regarding the calculation of K-values and R values - namely - Thermal Bridging. In Ashrae Fundamentals and ASHRAE 90.1 / International energy conservation code - there are values that are calculated separately for : 1. Wood Stud wall assemblies (Cavity Filled insulation batt) 2. Steel stud wall assemblies (cavity filled insulations) 3. CMU Assemblies (i.e. weight/cores grouted, ungrouted, filled or partially filled) 4. ASHRAE Fundamentals (Chapter 26 and chapter 33 respectively) There happens to be a predicament that is caused by composite materials vs traditional material types in VW 1. True R values cannot be determined from composite material k-values due to bridging calculated as noted in ASHRAE 90.1 and/or steel/wood reduction coefficients with insulated cavity walls, and / or concrete / masonry conditions with integrated insulation types. I.e. Masonry with grouted cores, or partially grouted insulated, partially grouted uninsulated, etc... 2. Do worksheets have the ability to subdivide composite materials in worksheets to show their respective counter parts? i.e. wood stud wall 16" o.c. w/ batt fiber insulation (is composed of two materials) - can worksheets show the composite material and their respective integral materials (i.e. batt fiber separate from wood stud wall partition) 3. Calculation of interior and exterior air film - is this automatically integrated into Energos? or should those components be added to each wall type? 4. Given that composite materials calculate composite k-value - based on the percentage of the respective components, an automated method's purpose of calculating UA values would be defeated (I think). Any ideas regarding this? As a result, my question is this : 1. What are the benefits of composite materials? What is their purpose, and how are they helpful to Energos or Energy conservation code compliance - other than finding the percentage value of components in their respective assemblies and multiplying them by their respective k / r values? This will certainly guide the material / composite material process - where i needed to decide to create CMU / grouted / insulated materials as a single material, or as a composite one? I know this post is long winded, hopefully we can have a productive discussion! Thanks in advance!

-

Try installing the latest mysql 8 odbc driver. The native one doesn't work, had similar issues. Also, use the universal driver rather than ansi Also note that you can actually access the database and have your password and login correctly I dont have Mac unfortunately, can't test it.

-

@Nikolay Zhelyazkov Thank you for your help! also - wish list item added!! https://forum.vectorworks.net/index.php?/topic/101918-graphic-legend-feature-request/

-

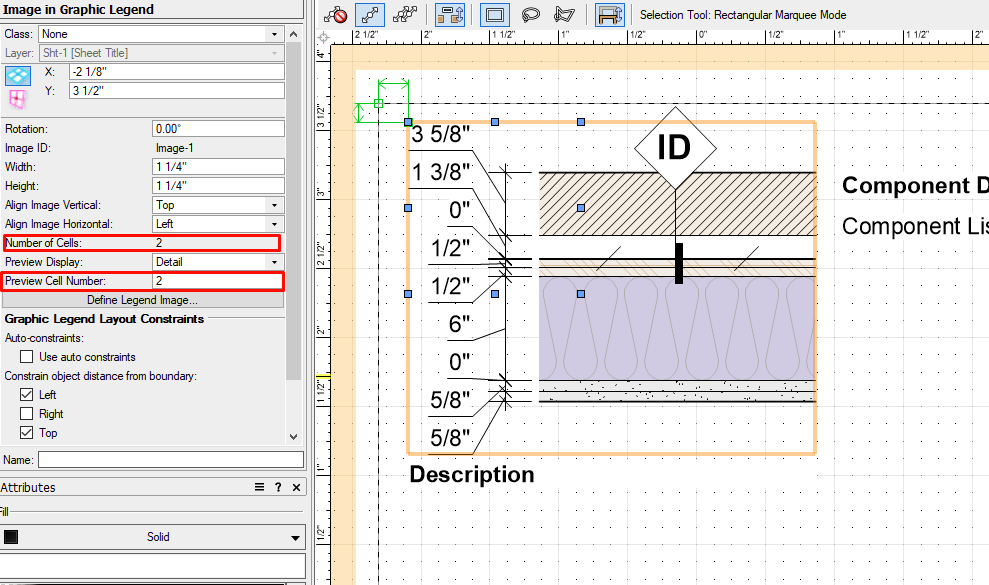

Graphic Legend Feature request

Samuel Derenboim posted a question in Wishlist - Feature and Content Requests

Recently ran into a problem in graphic legend referencing. In abstract, I believe the graphic legend tool has the ability to potentially eliminate drawing wall type details by about 50% if not more! Currently I am trying to use the Graphic legend tool to essentially do just that - create details for all the wall types, floor types, symbol types etc...to be used for current and future project in our office. I have succeeded in the most import aspects - extracting component and material information from these elements. There are just a few things missing - a scaling reference (one shown in GRAPHICLEGEND scale) and a number sequence for image cell numbers. It seems they already autopopulate the numbers given that each image can be previewed seperately as image cells (see below). These number can then be used as detail callout numbers from the plan (not necessarily referenced, but indicated / recorded). I think this would be a huge timesaver for many people here. DATATAG COMPONENT CALLOUTS.vwx My wish is to be able to extract this information into the dynamic text properties (i.e. #WS_Objectdata(GraphicLegend#, scale) or something similar, and #WS_Objectdata(Graphiclegend,cell number) or something similar. But here is the prefinal result! I'm attaching my reference file to show the remaining information that can be extracted from PIO's.-

- 4

-

-

- graphic legend

- incrementing value

- (and 3 more)

-

Implement Worksheet wrapping like this ...

Samuel Derenboim replied to Etienne_Mallee's question in Wishlist - Feature and Content Requests

I think it is an almost identical implementation of the new tool. I agree, Graphic legend feature will be a life saver! -

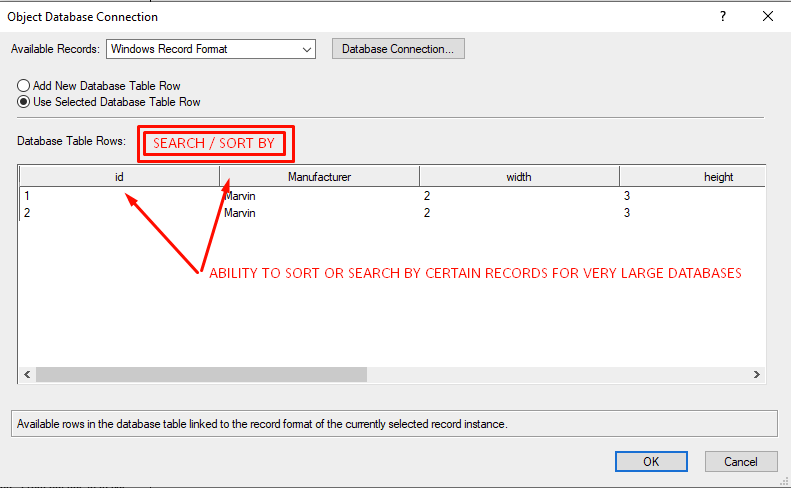

ODBC and SQlite remote databases is a beautiful feature in VW. In BIM Software in reference to Architectural Drawings and the entire AEC Industry has possibly become more about referencing information than just simply drafting plans etc... This is proprietary or generic information about building products, light fixtures, furniture, etc... Managing all of this information from a single source (VW) is extremely difficult. This is why ODBC and SQLITE in VW is so useful! If information can be referenced externally, it can also be Managed externally. Additionally, it can give VW an upper leg on competition with Autodesk Revit given that much of the informational libraries for Revit have been created by Manufacturers themselves. This however can apply record information to generic symbol library and expedite the process of creating massive symbol libraries. These databases can become quite large given the number of proprietary and standard building products. This information can include a lot of information including but not limited to specifications! Currently there is not sorting feature in ODBC and SQlite window. My request is to simply at a sorting function for record information, possibly similar to the way record information is sorted in worksheets database connection. I'm not sure if this is a big ask, but I think this could start the implementation of standardization in offices large and small that use VW

-

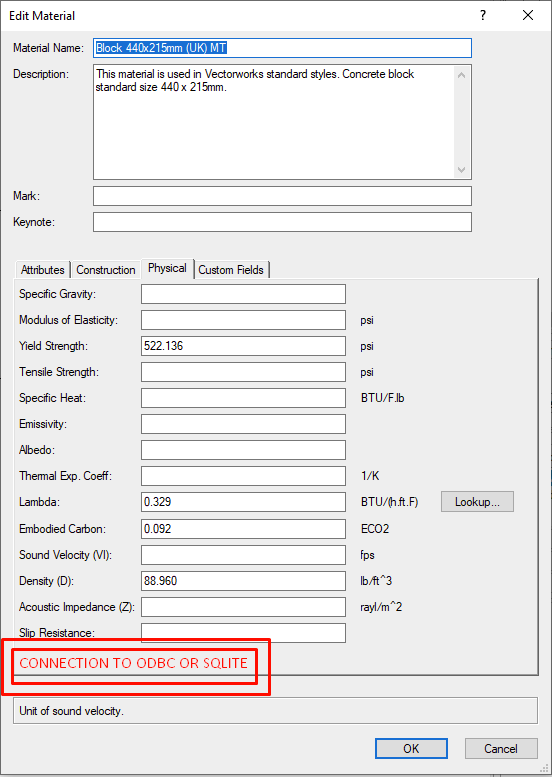

Creating a database of materials and specifications unfortunately is quite a tedious task and not always can be done inside of VW. Currently, when editing properties for materials, all physical / other properties need to be filled in manually. Given the number of permutations for material properties, the task almost seems unreachable when doing this manually (also especially when needing to update the information! ) What if we could populate it from a database (say that has a list of information regarding Building product information in HEAT, AIR, and Moisture Control in Building Assemblies - material properties from ASHRAE Handbook of Fundamentals,etc..)

-

As noted in the title, ODBC crashes VW after importing tables from ODBC, populating them to the required settings, and assiging the record to an object. When updating information, when I update the VW document from the attached database, it crashes VW. I have not tried this with an SQlite file. Process currently works in VW 2022.

-

@Phil hunt Actually there is, but the path is a bit convoluted. I used sketchup as a stepping stone to import the required textures. If you know how to use it do the following : after installing sketchup - go to sketchucation.com and download the store rbz plugin or find - fredo-import all from folder plugin. What this plugin basically does is it imports all image files from a directory. (this is how i imported over 5,000 textures into my library, and i'm still not done!) Once you import all the images, select all and explode them (that will populate the sketchup document file directory. Once imported and exploded, save the file. Afterwards, import the sketchup file into VW without erasing the geometry inside of the file. Once you do that, it should import as textures. Just be sure to input the correct names of the textures in the directory (especially if they are pbr textures) like texture a vs texturea_bump (I use an open source file renaming utility) etc.. Hope this helps!

-

@Nikolay Zhelyazkov Thank you! I'll double check the settings shortly. Pardon that I have so many questions but this is quite new to me. I did also want to ask 1. Is it possible to get the graphic scale of the image inside the graphic legend? I.e. if graphic legend image scale is at 1.5in =1ft, Is it possible to display it in the legend dataset ( I found it as a resource in the tag reference, but don't know how to call it out in #ws_objectdata# or #graphiclegend# / graphic legend image ) 2. Is it possible to 'count' every instance of the graphic legend in sequence? (I.e. if there are 16 details, each has a number for reference) I've been playing around with the database sequence settings, but I don't think it knows how to count every instance...perhaps there is a trigger? Thanks so much! Best Samuel

-

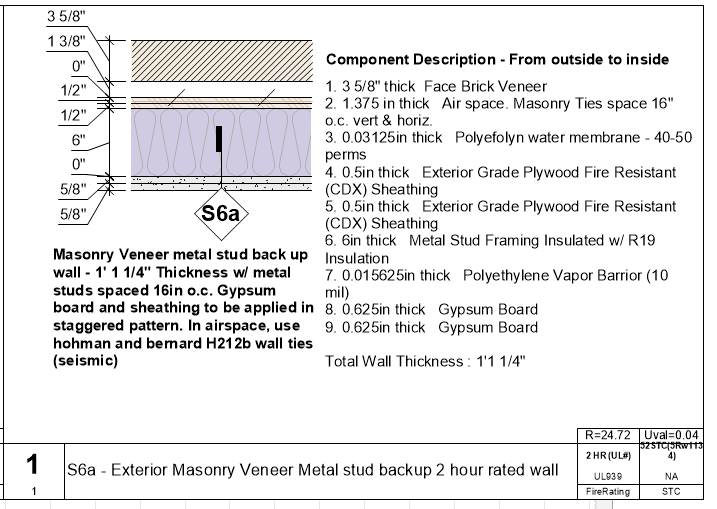

@Nikolay Zhelyazkov 🤯🤯🤯🤯🤯🤯🤯🤯 Mind = Blown I've never seen a conditional statement like that before in any of the data tags. Is this something new? Is this the only datatag conditional statement format? Just curious if I can read up more on the properties of these conditional statements. There is something to note however, the number is displayed as fractional feet, but the unit of measurement is inches. I have to actually multiply the value by 12 in order to get the correct dimension. Like so below : #WS_COMPONENTTHICKNESS(5)##fi_14_2#*12@#WS_COMPONENTTHICKNESS(5)#>0:' ' thick @#WS_COMPONENTTHICKNESS(5)#>0:' ' Why does it display 1/12 of the dimension? Is it because of units in the document? I've changed the units, still doesn't seem to change the value though. I don't mind multiplying by 12, just curious why it does this. Also, I have created a prototype graphic legend that intended to do the same thing, however, it doesn't work the same as it does for the datatag. One of the things that happens is that after the 1st line in the description, dimensional information reverts back to decimal and displays foot information rather than ft/in information. I know it sounds confusing. Attaching the file here. Nikolay, Thank you in advance! You're a tremendous help!!! DATATAG COMPONENT CALLOUTS.vwx

-

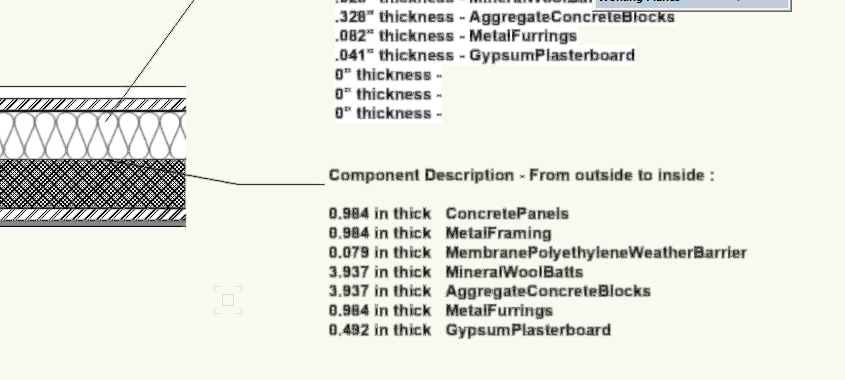

@Zsombor@Anders Blomberg Good news, You can enter conditional statements into data tags. The element you were concerned about was values being shown when they were zero. See Screenshot below Note there are only 7 layers attached. Component Description - From outside to inside : #WS_IFNA((OBJECTDATA('component', 'thickness', 1)), ' ')# #fi_3_2# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 1)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 1)# #WS_IFNA((OBJECTDATA('component', 'thickness', 2)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 2)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 2)# #WS_IFNA((OBJECTDATA('component', 'thickness', 3)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 3)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 3)# #WS_IFNA((OBJECTDATA('component', 'thickness', 4)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 4)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 4)# #WS_IFNA((OBJECTDATA('component', 'thickness', 5)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 5)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 5)# #WS_IFNA((OBJECTDATA('component', 'thickness', 6)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 6)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 6)# #WS_IFNA((OBJECTDATA('component', 'thickness', 7)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 7)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 7)# #WS_IFNA((OBJECTDATA('component', 'thickness', 8)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 8)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 8)# #WS_IFNA((OBJECTDATA('component', 'thickness', 9)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 9)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 9)# #WS_IFNA((OBJECTDATA('component', 'thickness', 10)), ' ')# #WS_IF(VALUE(OBJECTDATA('component', 'thickness', 10)>0), 'in thick -', ' ')# #WS_OBJECTDATA('component', 'name', 10)# I'm still working on a tidier method however. Since there are conditional statements, its possible to make this a much more elegant solution! @Nikolay Zhelyazkov I was wondering regarding the information above - 1. Is there a function to call out component index ? i.e. 1, 2, 3, 4, etc... I have looked through all the variables in the insert function context menu in the worksheets, but have not found anything. 2. Is there a way to display the dimensional information of values to fractional inches or feet rather than decimal inches / feet in the datatag layout I tried to use #fi_3_2#, but it doesn't work. Is there something that I'm missing? Thank you in advance!

-

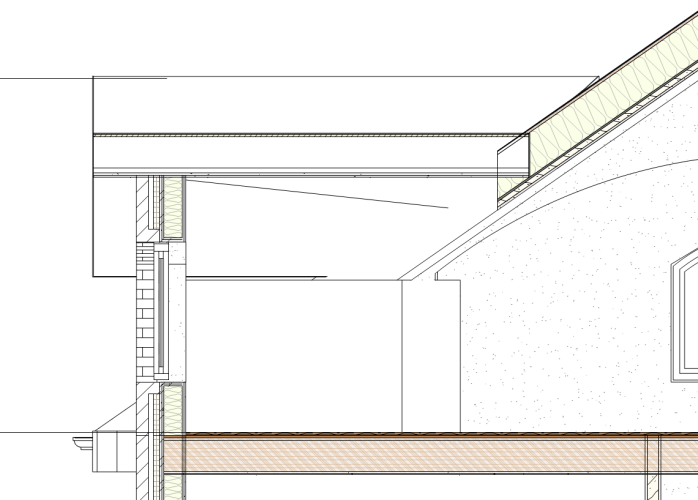

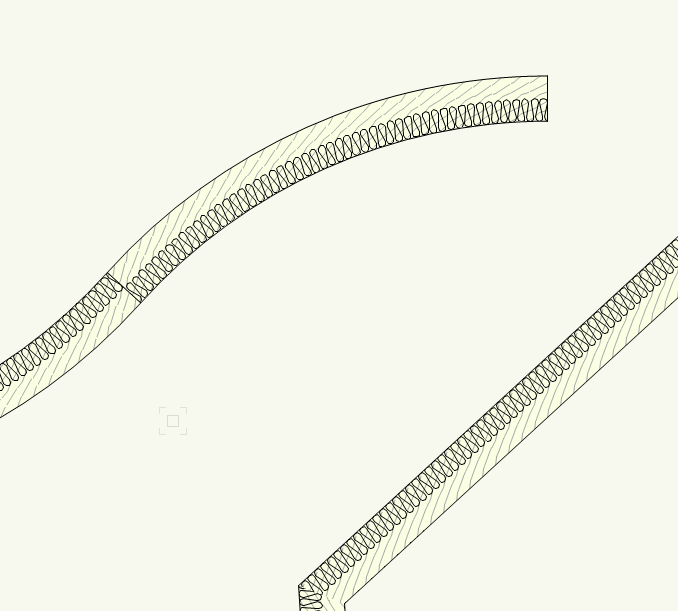

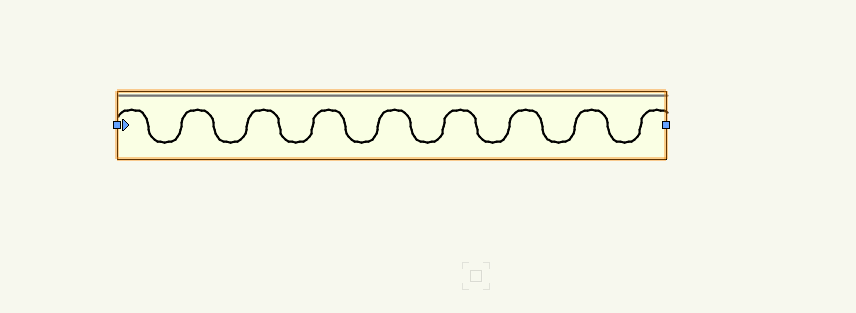

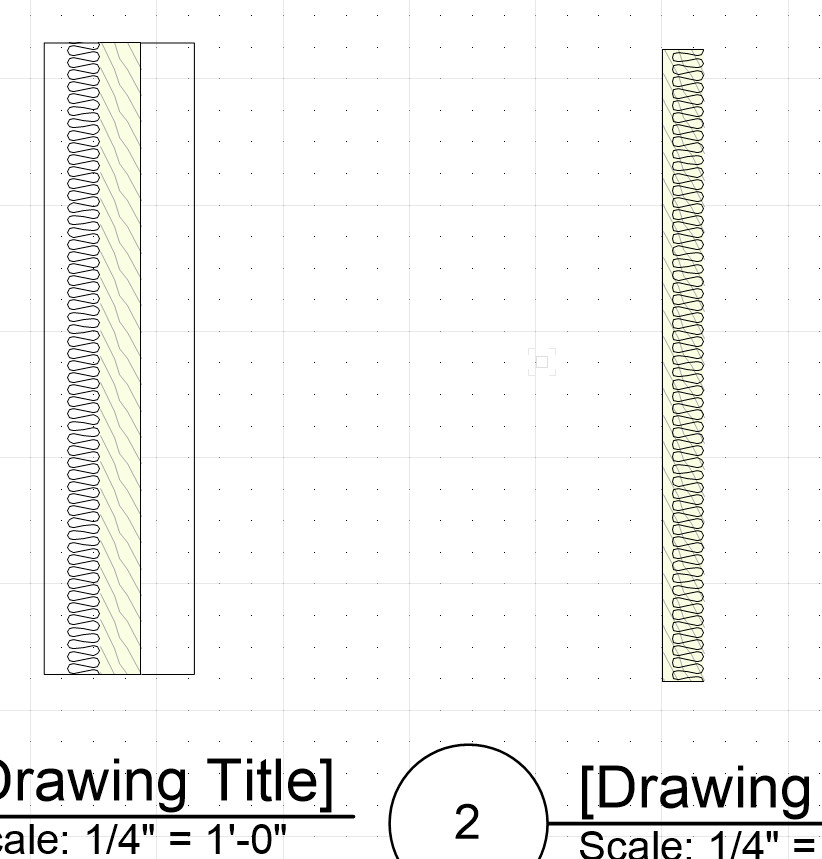

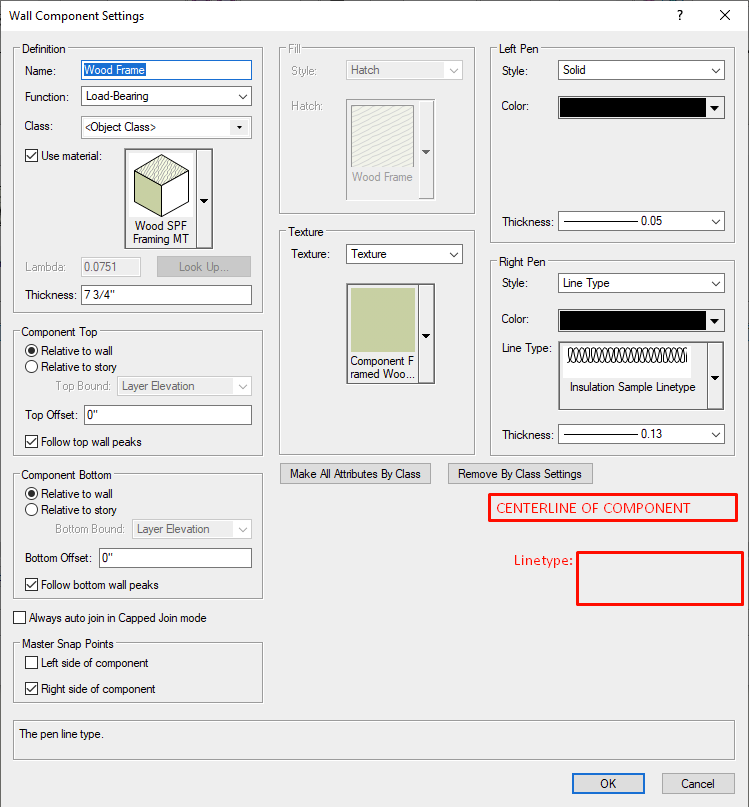

With the addition of various materials and components, it would be nice to provide various hatches for insulation, (i.e. Rigid, friable, mineral wool etc... between centerline spacing) or various other configurations. I have attempted this with hatches and tiles. see below : When using linear configurations, the tile can reverse positions in plan like shown above. Tiles also have an inability to be exported as hatches to autocad. Something to note! When it comes to hatches - A good example of hatches do not tile appropriately because they do not have a starting point. Therefore if the wall moves, the hatch tiles differently (in both world view as well as page view). The good news it can export to dwg. Last experiment included using offset custom line types along component lines (left of right). However this has a major flaw - line types are reversed when using different section wall views such as this. Here is an example. The two section viewports are referencing the same wall type. However because the line type alignment is on one side, the line type reverses (as seen on the left) when the viewport switches direction. As such, the request is to have the opportunity to provide a linetype for the Core or Centerline of the component to have a more variable ability to create wall styles\roof styles\slab styles\hardscape styles with linetypes that can be exported to autocad properly as well as beautiful looking wall styles. See example below Given that vectorworks outputs the most beautiful construction drawings of any software I have used in the past, I would say this would make a nice addition with your approval!