-

Posts

667 -

Joined

-

Last visited

Reputation

22 GreatPersonal Information

-

Occupation

architect / 2d-animator

-

Homepage

www.gesterworks.net

-

Location

poland / austria

Recent Profile Visitors

2,707 profile views

-

.ids (information delivery specification) file import

gester replied to gester's topic in General Discussion

ids is an xml-type of file, very standardised. i mean the import procedure which might be similar to excel imports. it was not comparing both standards (xls and ids). -

.ids (information delivery specification) file import

gester replied to gester's topic in General Discussion

i've just watched the vw 2024 excel referencing video. i think the ids case could be performed in a similar manner: just importing ids in the excel-import style. of course, it's just an idea, i still dunno if it makes sense and how to implement it. such import would have to go directly into ifc properties (or via data manager), not as a worksheet... -

.ids (information delivery specification) file import

gester replied to gester's topic in General Discussion

you really need bsdd matrix in vectorworks? it's an external link between the ifc guids and the classification and real life objects, containing rfids, qr's, or gs1 gtins. we need ids in the first place, just in order to populate our ifc models with properties. btw: i don't see pictures in the translated computerworks presentation. can you provide the link to the german version? -

hi, is the importing of the new information requirements format (development supported by buildingsmart int'l) named .ids (information delivery specification) planned, or maybe already in the pipeline? this format is both machine and human readable, and is supposed to import owner's requirements (now governed by paper-based documents: air - asset information requirements, pir - project information requirements, and eir - exchange information requirements, these are destined to be abandoned in the future) into the properties that can be used for the ifc data exported from the application. do vectorworks, inc. think about it? bye, rob

-

set-based design (various design versions kept in one vwx file)

gester replied to gester's topic in General Discussion

i'm an advocate of a _one_ common exchange format. we have too much dark data in the construction industry, and no converter is reliable to not to lose data during translation. that's why blenderbim with the native ifc is such a highlight. yes, i know it. -

data visualization directly in the project model

gester replied to gester's topic in General Discussion

yeah, probably it'll be right. i just have to check, i'm not at the computer with the vw installation. -

data visualization directly in the project model

gester replied to gester's topic in General Discussion

so as i get it, for my initial wall colours visualization example: 1. i save the original view with my walls 2. i change the colours for those walls according to their fire resistance values 3. save this new view 4. recall the original saved view (must check if the original colours can come back) is that it? -

set-based design (various design versions kept in one vwx file)

gester replied to gester's topic in General Discussion

what would be the functionality of the speckle connector for vectorworks? what do you expect from it? -

data visualization directly in the project model

gester replied to gester's topic in General Discussion

for the viewports... -

set-based design (various design versions kept in one vwx file)

gester replied to gester's topic in General Discussion

yes, i've expected this, and actually it's a bit cumbersome. i hoped for some simpler workflow. thanks, anyway. -

hi, another question after the viewing of the archicad 27 webinar: is it possible to do datavisualization in vectorworks file, except that not on the viewports, but directly in the model? e.g. colouring of the walls according to the different fire resistance (red - 60 minutes, orange - 30 minutes, yellow - 15 minutes) directly in the model, and save it for future views... thanks, rob

-

hi, i've just watched the archicad 27 webinar and i'm just wondering if it's possible to have many versions of the design solutions parallelly in one vwx file? in archicad there's a commitment button which links the chosen version into the current project, the other versions are being removed. the versions can contain any set of options referring to selected model elements. these options are then added to the aproppriate versions. eg. version 1 has a steel construction, version 2 has a concrete one, a.s.o. the reason for this query is the target value delivery method from the lean construction, where you postpone the design solution choice until the lrm (last responsible moment), where all other options can be rendered obsolete. thanks for any help. rob

-

Embodied Carbon Calculations, Sustainability and Energos

gester replied to Asemblance's topic in Energos

hi, does this vecc tool work only with the us window and door styles? i use benelux windows and doors, a different type… thanks.- 23 replies

-

- energos

- sustainability

-

(and 3 more)

Tagged with:

-

cove.tool is supposed to connect to vectorworks via plugin to be released this march. 1. is this already working? 2. is it available also for localized versions of vectorworks? rob

-

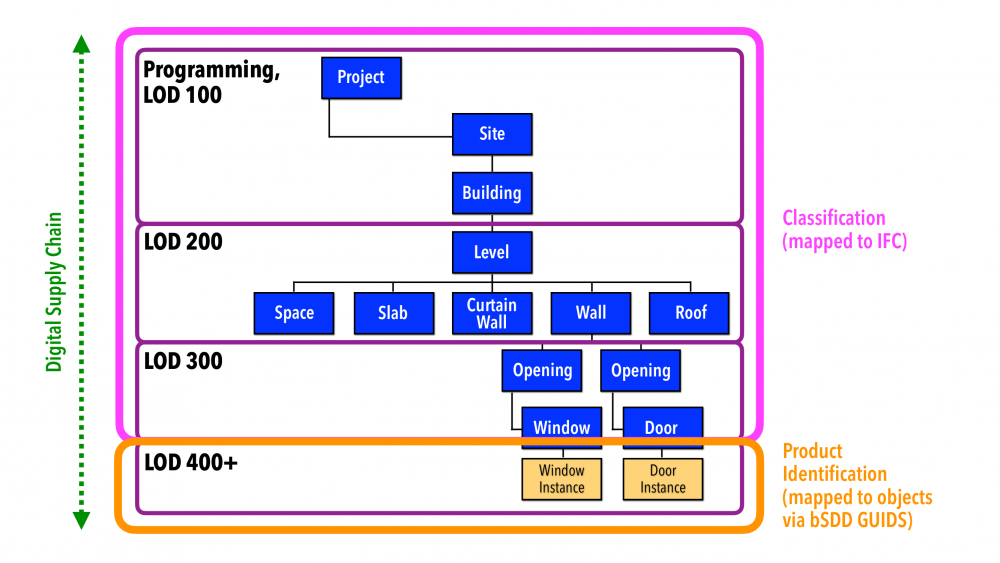

here's my take on the connections between ifc structure, bsdd, classification, product identification and digital supply chain... rob