-

Posts

1,191 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Sam Jones

-

-

9 hours ago, Stefan B. said:

And, as a rigger who does plan the trusses

But you are not the only one who uses the trusses

9 hours ago, Stefan B. said:But it is very possible to hang a fixture in a truss that is not in a hanging position.

But it is possible to make every truss assembly that has fixtures hanging from it a hanging position. There are advantages to hanging positions. Either as a lighting designer or production electrician, I would convert any truss assemblies I found, and use, to hanging positions. When you are laying out the truss assemblies, they don't need to be hanging positions, but once you pass them off to the LD and/or PE, boom, lighting positions. (Not true for all LDs and PEs, but for many of us.) What kind of global changes do you make after the layout that makes double clicking on a hanging position so onerous?

-

11 hours ago, Stefan B. said:

In my opinion, a truss should never be a hanging position!

Why? It seems to work very well, especially when used for hang lighting fixtures.

-

-

23 hours ago, Kevin Allen said:

is this possible with @Sam Jones Cable tools?

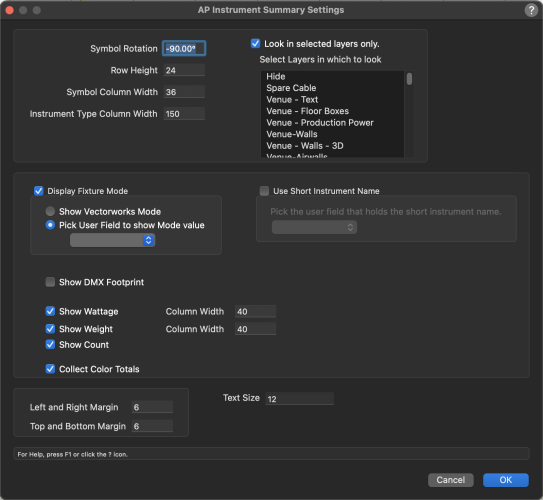

With AutoPlot Cable Tools, yes. However, those tools will not be seen by Braceworks. You would need to place load indicators if you want to include them in Braceworks calculations. Those tools prioritize part control and reporting; they are not better, just different.

-

1

1

-

-

18 hours ago, Mark Aceto said:

you have to pick a different field, start at 1, then pick the field you want, deselect the other field, then start at 1… it

You can just edit the start field to start at the number you desire.

-

1

1

-

1

1

-

-

Back in 1992, I was asked by my lighting faculty to see if PowerCAD or MiniCAD 4+ could do what we desperately needed, talk to an outside database. As far as we knew that functionality did not exist, anywhere. We didn't have that much experience, and there might have been a LISP implementation in AutoCAD 9 at the time, but we had not heard of it. I took both home. I saw in the manual that MiniCAD 4+ had the functionality of link text to record and macro language that was a superset of PASCAL. I knew PASCAL, and it had Readln and WriteLn. We never looked back and implemented the first functional lightplot that could talk to a database, Panorama at the time. Later, as soon as Lightwright was ported to the Mac, we talked to LW.

Arguably, that made MiniCAD and vectorworks dominate in the entertainment industry. The rest of the rest of the functionality in Vectorworks was whipped cream. With all its flaws, and there are several, I love PASCAL.

-

2

2

-

-

Python's string handling is famously more powerful, but none of what you describe would seem to need it.

1. VS function "UprString()" will convert a string to upper case

2. My only experience with title caps is as a font. I would convert the string to that font using "SetTextFont()"

3. Changing the color of text is just a matter of setting its color with "SetPenFore()"

If you need help with how to use vectorscript itself that is a whole other ballgame. You would need to describe exactly what you want to achieve and show us how far you have progressed and where you are stumped.

Lastly, do you want an example vectorscript? If so, to do exactly what with what?

-

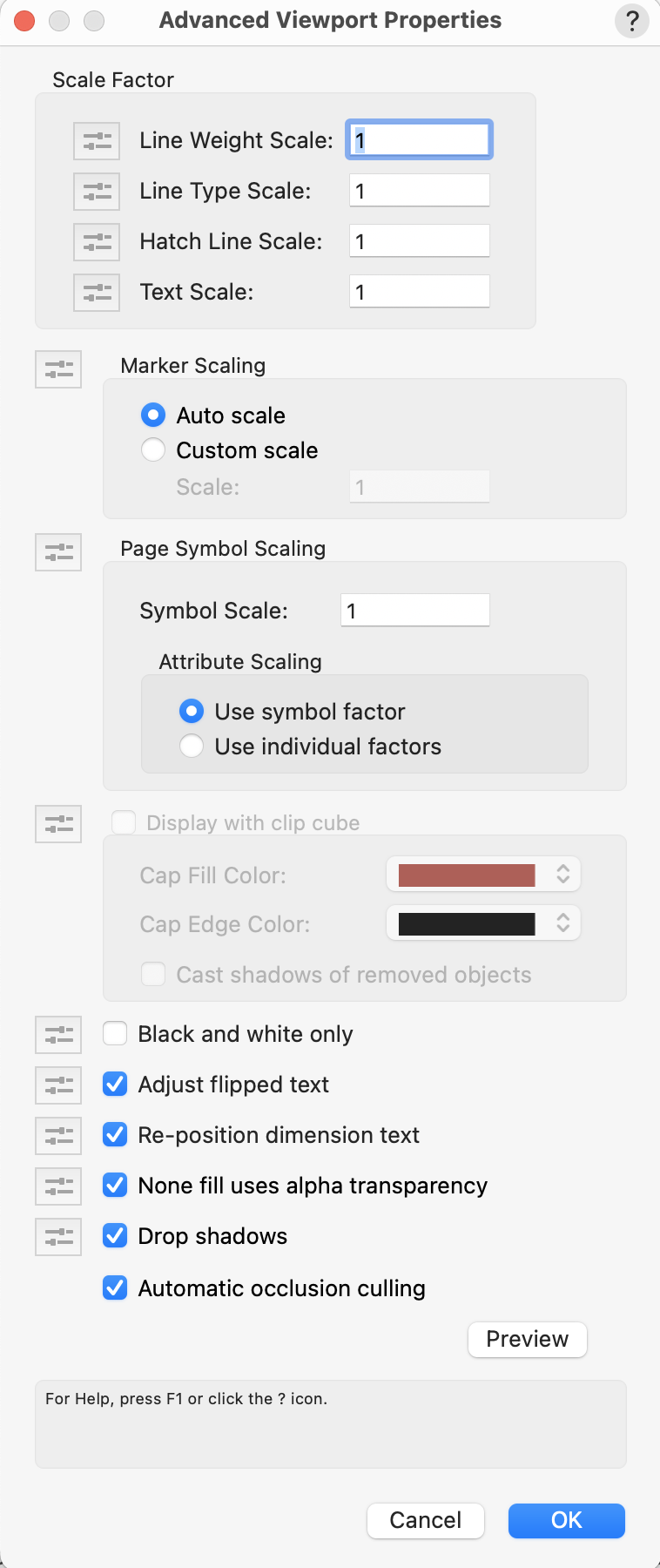

Adding to what Pat said: Layer units are in what are considered by the program as "world units". However, when you specify line thickness and line endings (arrows and such) they are placed on the design layer in "page units". I don't know what those are or how they do that, but it is supposed to make the those features more consistent from layer to layer. You have experienced how that works out. Regardless, this results in the "rule" Pat mentions above. Make the scale of your design layers as close to your most often printed scale. If you need to adjust those sizes in viewports that have an uncommon scale you can do that by scaling them in those viewports by pressing the "Advanced Properties" button at the bottom of the viewport's OIP and adjusting the values in the dialog below.

-

2

2

-

-

On 12/17/2023 at 9:30 AM, michaelk said:

(I always need to check every idea I have for a script or plug-in to make sure @Sam Jones hasn't already written it.)

You and @Jesse Cogswell are usually ahead of me unless it was really simple and deals with the Lighting Device. If that is the case, I wrote it 20 years ago.

-

-

34 minutes ago, line-weight said:

Well, maybe let it be enabled/disabled. But it's not a legacy feature - it's a feature that's required for current workflows to work.

Nobody is advocating that the feature go away. We just want to get it out of our way. Let me hide it or doc it. Every time I edit a symbol I have to move that damn palette. It is easier to move between 3D symbol editing and 2D symbol editing than it is to move the stupid component edit palette out of the way every time, sometimes more than once in a symbol editing session. Why can't I hide it or dock it? If you need it, you get to have it. If you don't need it, it gets to slap you across the face every time you edit a symbol. I did have this discussion with some of VW at the LDI trade show. What I took away from the discussion was that they don't care; they have other fish to fry.

-

3

3

-

-

The basic part of your request, is achieved as Michael shows with the link text to record. This requires that the symbol have a record attached. You can attach the record to the symbol and then place pieces of text that you link to the record fields using the "Link Text to Record" command. How you edit the field values of the record is up to you. You can use the worksheet database of the attached record or you can go to a symbol and edit the record fields in the Data Pane. Use whichever method suits you at any time.

The AutoPlot tools use this functionality a lot. Its most obvious use in the tools are the "Make Truss Tape" command and the "Print Labels" & "Print Labels from Worksheet" commands, but there are many other commands that use the functionality to achieve different things.

-

1

1

-

-

Just a little more clarity.

You want a list of hanging Positions, 1 hanging position per row. Yes?

You want the cells from column B to list the fixtures attached to that hanging postion. Yes?

You want one type of Lighting Device plus the total number of that device type to populate each cell (per device type) to the right of column A. Yes?

How do you want to handle Accessories?

-

30 minutes ago, AStein said:

I think truss tape alone for layout would be problematic because of how fragile it is, but something like that would look slick... Maybe a roll of vinyl?

I have been told by user that are heavy duty, durable rolls of receipt tape available.

-

It is relatively easy to make floor stickers in AutoPlot Tools. I haven't had a chance to make a video yet, but if anyone wants a walk through, let me know. Also, some are also using truss tapes for motor layouts on the floor.

sjones@autoplotvw.com

-

Ah..., the comment interface could be better.

-

@Kevin Allen really? You think the current cable break indicators are adequate? I have never heard that from anyone who does cable planning, but I have only interacted with a small set of production electricians that regularly do cable planning, and I know there are many out there attempting to use the power planning tools. I would like to hear from any others who find the cable break indicators adequate and not in desperate need of improvement. For me, and my colleagues, they just don't do the job, but perhaps we are in a shocking minority.

-

5 hours ago, Stefan B. said:

2. It would be great to be able to set the size of the sphere or locust. But this should also be possible to do under OIP after the cable is inserted. So one can alter the size of them to what fits that particular drawing.

I consider the size, the optics, of the connector marker to be a small disaster. It is so important to know where the cable connections are in a cable run, and the current connector markers are close to invisible. I admit that I'm two versions behind, but if this has not changed, it makes managing cable parts so terribly difficult. This should be an easy fix. Anything from the simplest and least desireable of making the sphere larger and darker, to letting the user pick a symbol of their choice. There are in between options like giving the user control over the size and fill of the sphere. Currently, I have to spend minutes finding a connection. That's absurd.

-

2

2

-

1

1

-

-

1 hour ago, SamIWas said:

I'm more curious about getting different drop-down values conditionally based upon a different drop-down's value. Looks like something else to have fun learning!

If we are not talking about the default OIP, this is easily done. In the Reset Event, you need the following statements

IF vsoStateGetParamChng(PIOHan, OutWidgID, ParamIndex, OldValue ) THEN

BEGIN{Check if the changed parameter is equal to the one you want to base the change of another parameter on}

{Get the value of the changed parameter}

IF theValue is a signal to change another drop down THEN

BEGIN

booResult := vsoPrmName2WidgetID('',NameOfParameterToChange, OutWidgID);

vsoWidgetPopupClear(OutWidgID);

FOR index := 1 TO NumberOfChoices DO

BEGIN

vsoWidgetPopupAdd(OutWidgID, NewValue[index], NewValue[index]);

END

END; {IF theValue is a signal to change}

END; {IF vsoStateGetParamChng}

-

29 minutes ago, AStein said:

Riggers talk. You want them talking about how cool their new tool is, not exchanging ways to work around it. Right now everyone seems very excited about Production-Assist... Basically a massive workaround with a license model that makes it affordable. There's no good reason Vectorworks couldn't make that money instead.

I have talked to a number of riggers, ones that use Braceworks, ones that use Production Assist, ones that use both, ones that use neither. What I have yet to gleen is a list of needed tools and functionality. For now, I would leave static analysis out of the list, Braceworks and Production Assist do this, and both are coded by the same guy. If one doesn't use them, they do the calcs themselves, or send to a structural engineer, or both. What is your workflow and what are the tools you need to assist you as a PR? Is Production Assist enough? Is it too much?

-

-

What is the format for specifying the selection of a worksheet cell when there are no subrows in the worksheet, and even if there was, what would the format be for selecting a cell that is not part of a subrow?

PROCEDURE SetWSSelection

( worksheet:HANDLE;

currentCellRow:INTEGER;

currentCellColumn:INTEGER;

topRangeRow:INTEGER;

leftRangeColumn:INTEGER;

topRangeSubrow:INTEGER;

bottomRangeRow:INTEGER;

rightRangeColumn:INTEGER;

bottomRangeSubrow:INTEGER

) ;

I have tried not including any subrow specification, putting "0"s in the subrow specification, and putting the cell row, col values in the subrow specification. None of that works.

-

8 hours ago, Scott C. Parker said:

paging @Sam Jones

Although AutoPlot Tools for Spotlight will allow you to specify the location of a clamp accessory, the @jcogdell method seems to me to be another good way. However, if you are planning on counting clamps, you will need to be careful with specifying the counting criteria and/or being sure that the double clamp symbol contains to symbols to count. (I think. I haven't played with this method.

-

5 hours ago, MullinRJ said:

God bless Carlotta !!! 😇

I sooooo miss her!

-

2

2

-

Cable not interacting v2024

in Entertainment

Posted

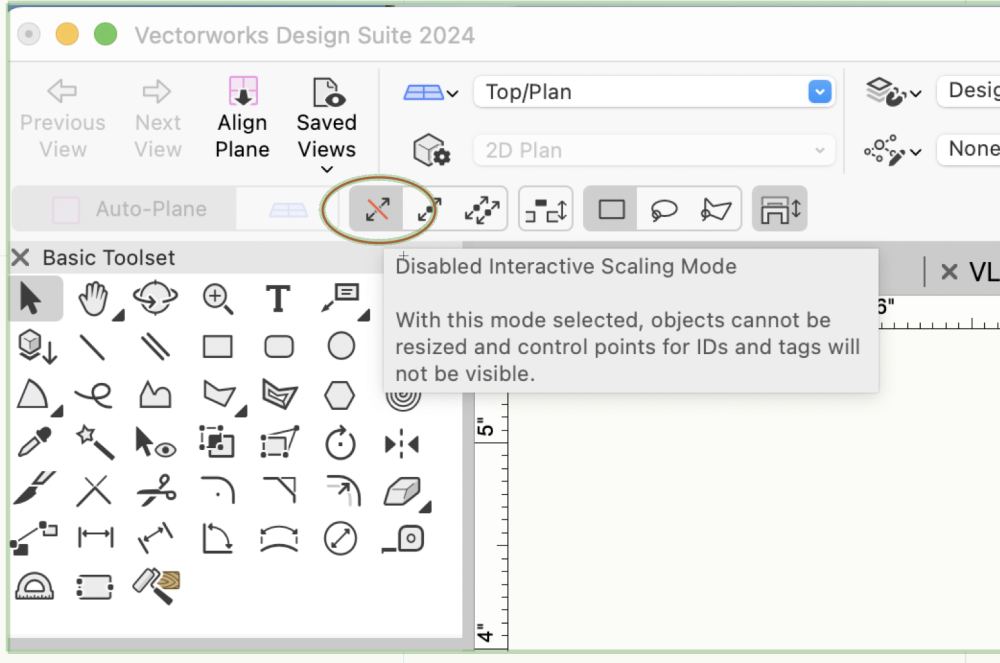

Sharing position changes, automatic numbering, total hung weight in the OIP, and automatic position acquisition; although without care and experience, this can bite you in the ass.