-

Posts

64 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by blanger

-

-

I think I'm following now. I had this situation which was pretty annoying and could be solved by a revised approach. I had two walls that required different thickness both with the same finish. I needed 2 wall types, one for each thickness and then if I revised the finish I had to update it in both walls.

-

2

2

-

-

5 hours ago, michaelk said:

Which version of VW are you using? This is a relatively recent feature.

I tried earlier today on VWX 2022 Service Pack 3... it didnt work until I got service pack 4. AND ITS GREAT!

-

1

1

-

-

Please remember that architecture is not the only application. For set design purposes I often wish for more integration. For instance the ability to include base mould as a wall component would be a huge plus for Set Design. I'd say we work primarily with wall finishes and the flat itself is the simplest element. @Andy Broomell do you have any opinions on this?

-

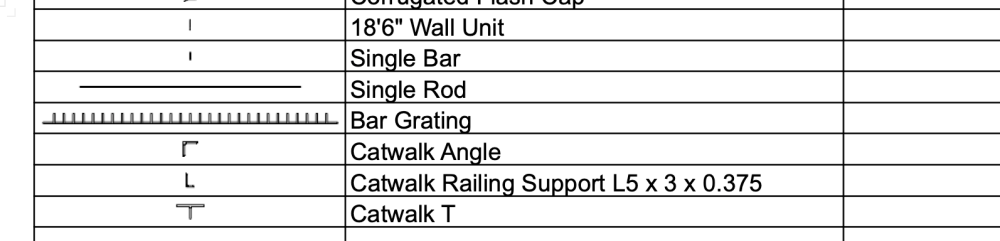

In case anyone is following along I found this great video by Jonathan Pickup that showed my how to Data Tag structural members. This is wonderful as it lets me pull the type of into my annotations - - too bad I used the individual 3d profiles instead of structural member tool. I wont make that mistake again (I wonder why the individual member tools even exist unless they predated the more complete structural member tool).

This shows my beam pulling info from the object itself using a data tag with #StructuralMember#.#ProfileSize# and #StructuralMember#.#MemberID#

-

@Pat Stanford Is it further possible to put a number or letter in a field associated with each symbol and use a data tag to mark the symbols on a plan in viewport and include that number in the worksheet.

I haven't successfully labeled symbols yet with data tags but I have big dreams! -

On 7/1/2022 at 4:27 AM, clewy said:

Hi,

I am having an issue with the creation of bespoke sized structural members that I hope somone may be able to assit with.

We utalise bespoke girder plate beams (75mm x 200mm x Length), which I am attempting to add as a custom structural member. I can select 'Member Type: Custom' and see a set of pre-filled material sizes, but cannot for the life of me work out how to edit these or import a custom shape with these dimentions?

Could anyone point me in the right direction?

Thanks,

CallumDraw a rectangle at 75x200 and save as a symbol. Select "member type :custom" in the framing tool, scroll down to the bottom of the OIP. "Choose Profile Symbol" navigate in the resources that come up to your current open file where that symbol of 75x200 is and select it. 👍🏻

-

3

3

-

-

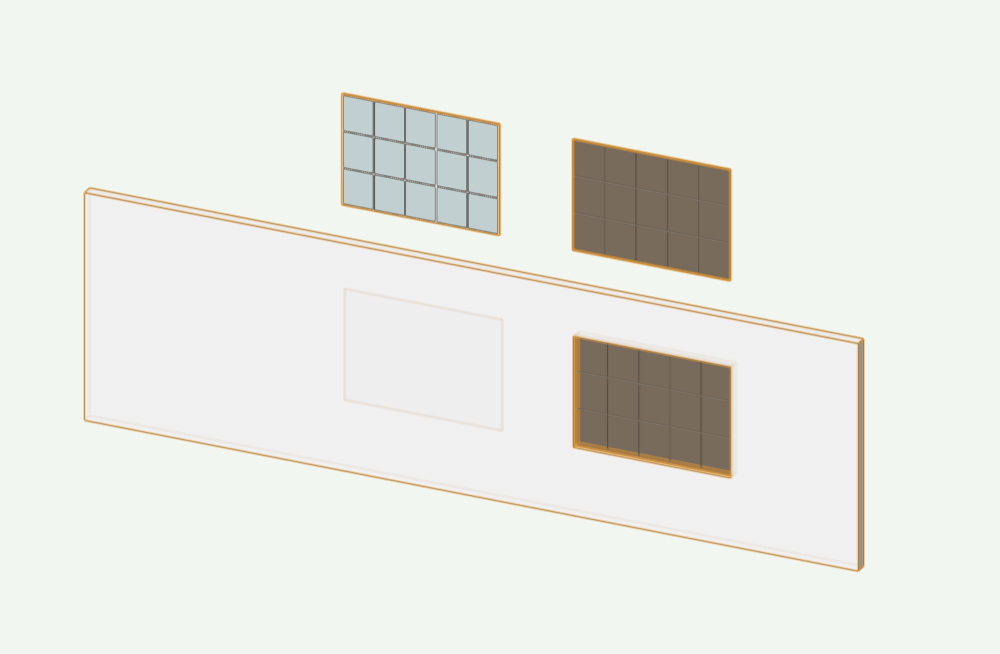

29 minutes ago, Pat Stanford said:

The one with the brown glass has the Autohybrid inside the 3D part of the symbol in a group. The one with the blue glass does not.

Edit the blue glass symbol, 3D component, select all, group.

It should work.

And I do know know why an auto hybrid needs to be in a group to work as part of a symbol in wall.

AHA! So Strange - Auto Hybrid then Group then Make Symbol if I want to insert in the wall. I always avoid grouping if I'm going to make a symbol to skip a step. Thanks!!!

-

10 minutes ago, Andy Broomell said:

Yeah that's super weird...

As for the 2D representation, the two windows appear to be built at different Z heights (notice they're currently at 3' & 5' in the OIP to compensate for this). If you adjust the brown-glass window to have an Auto-Hybrid cut plane at 0", the 2D representation looks correct. Or you could go inside the Auto-Hybrid and move the 3D geometry on the Z axis so it matches how the other one was built.

Son of Sailor! So the Auto-Hybrid Is relative to the axis for that object - I thought it was relative to 0 on my layers. Thanks for the fix - - you got me into this whole symbol in wall mess anyway!... Also you can see how I decided to make the window - pretty simple to do it as 2 extruded shapes rather than a bunch of extrude along paths. Thanks as always!!

-

I'm banging my head against the wall!

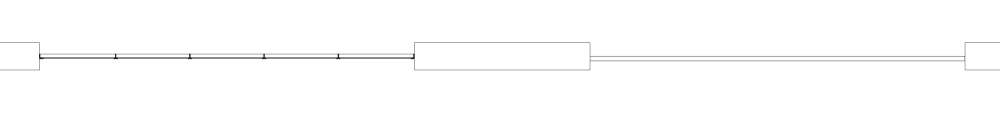

2 Windows that I made into symbols.

The one on the left I can get the Auto Hybrid to work and show me the muntins correctly. But the glass doesn't appear correctly and when placed in wall does not cut a hole in the wall in 3d.

The one on the right has glazing that appears correctly and cuts the hole in wall in 3d but will not display correctly in plan.

WHAT AM I DOING WRONG!!!??? I've already wasted too much time today on this 😞

Thanks!

-

- Popular Post

- Popular Post

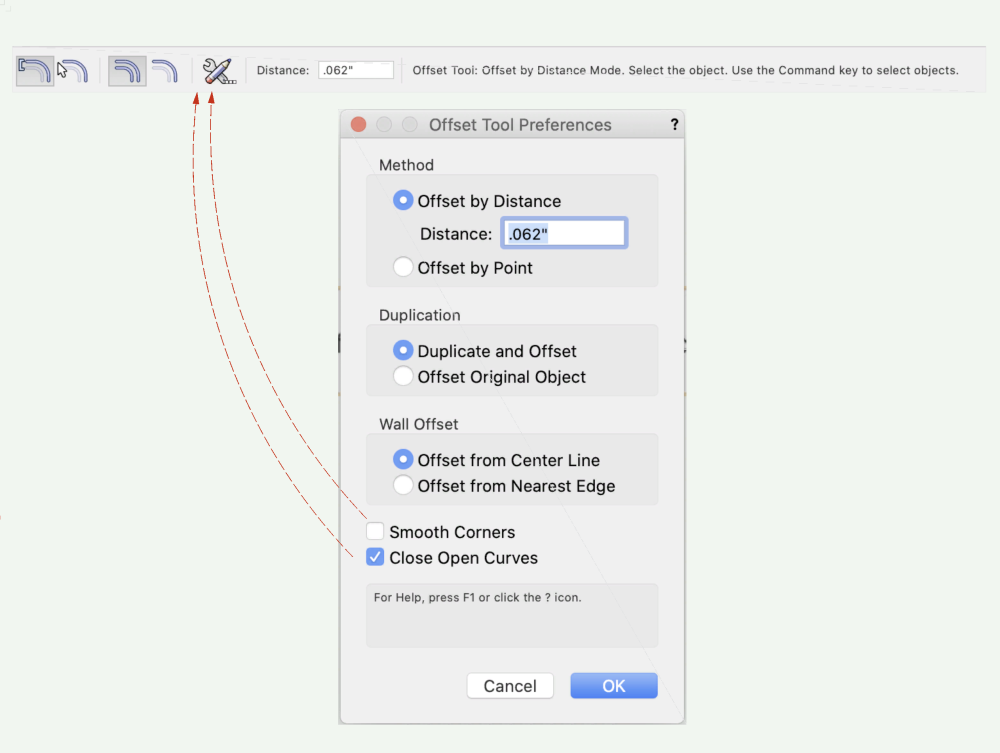

I love the offset tool...

I love switching back and forth between "Close Open Curves" being off and on.

I do not like going into the Offset Tool Preferences every time to toggle it.

Please add this as a toggle button on the sub menu for the Offset Tool.

(I don't use Smooth Corners really but maybe that belongs too)

🙂

-

5

5

-

4 hours ago, Andy Broomell said:

While it depends on the show, I'd probably model the whole thing in detail (which honestly isn't too complex when everything is rectilinear) and, if useful, possibly save it as a custom symbol with a Wall Hole component.

Or, if short on time I might choose to model a simpler version where I essentially extrude the "silhouette" of the elevation, so the muntins are the correct width and layout but end up just being rectangular instead of real profiles.

Sometimes I take the Window object (which I had started with for general size and proportion), and set it to Opening or Cased Opening, then just add my custom geometry within that opening. And perhaps make that geometry an Auto-hybrid for the plan representation.

If I modeled in detail, then the Design Layer model can be used for plan, elevation, & 3D views. But for my FSDs I often choose to go 2D-only since you have much better control over attributes (and I care about aesthetics!) So for any of these 'hand-drawn' details I'll go to a Sheet Layer, make an 'empty' viewport, then draw or paste in profiles. When all linework is 2D it's also easier to move things around, use the Reshape Tool, compress things, add break lines, knock down edges, etc.

BTW I might start with a Section Viewport of the 3D model as a placeholder since I've already figured out the geometry there, then eventually replace it or Annotate on top of it with 2D profiles.

It's all a nuanced process that I adjust and adapt for each set piece depending on what's best in the moment (and perhaps my mood?). Hope this helps.

What helps the most is knowing that you flow with different processes depending on time and situation. That in and off itself makes me feel better! I've done most of not all of the above methods and have been switching between them. Lately, in some fsds, I've even been turning off all layers after using the model section as a baseline to annotate over, seems like you do the same.Inspired by your door tutorial I just made my first few symbols to place in walls. I love it! Thank you!!!!

-

37 minutes ago, Andy Broomell said:

I was going to say... The window tool is SO far away from being able to do that 😆

@Andy Broomell Dream Crusher! I started to investigate windoor but that doesn't seem to have it either. Would you recommend building the whole thing and sectioning, or building with window tool and then drawing sections in 2D?

-

3 hours ago, Christiaan said:

Not specifically, no, but what is it about them that the current window tool can't do? Maybe I have a more generic wish covering it?

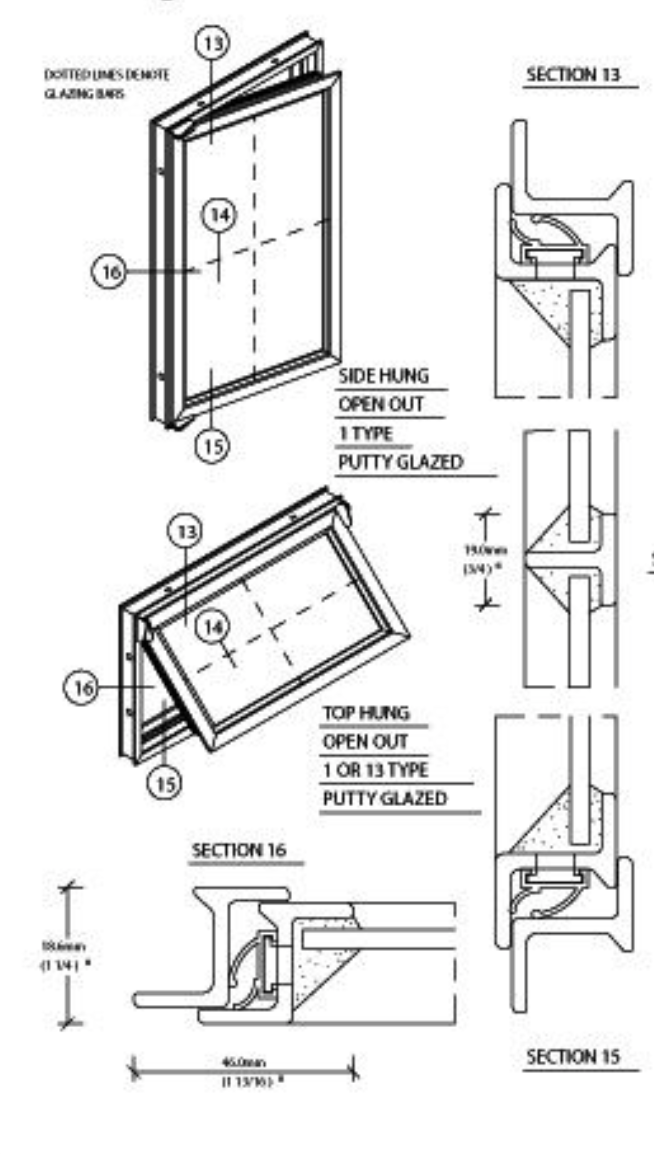

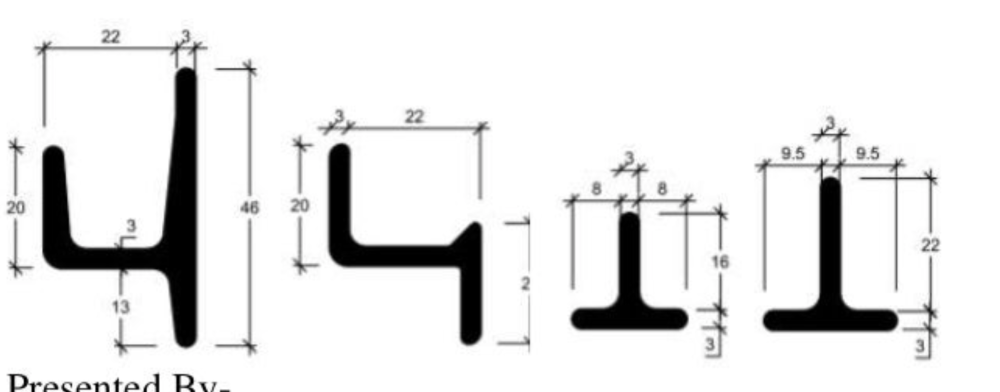

I'd love to be able to use typical steel profiles "T" Shaped Glazing Bar or Muntin, The Sash and the Frame so that when sectioning the profiles are correct. Coming to think of it, when I do wood windows I don't even get the ogee profiles of typical wood windows... so maybe Im reaching too far. 🙂

-

1

1

-

-

@Christiaan Do you have steel warehouse windows included somewhere in the wishlist for windows? I'd like to know before I make a wishlist item. 🧞♂️

-

1

1

-

-

18 minutes ago, Pat Stanford said:

To get the quantity use a column with a formula of =Count

To limit the objects being shown you need to edit the Database Criteria. Right click on the Database Header Row (ie 3, not 3.1. 3.2, etc) and choose Edit Criteria. Add an additional criteria for Class or whatever you need to limit the functions.

Another possibility would be a script that would run through all of the structural objects in the drawing and store the series and size into a custom record. But you would need to rerun the script to ensure the data is correct if you changed any of the sizes. This could then be accessed either in a worksheet or a data tag.

Brilliant!

The scripted prospect is really interesting but since I don't work with steel as much this symbol approach is great because I will be able to apply it to all kinds of projects, like number of pistachios in a bowl... jk.

Thank you so much!!! I appreciate you!

-

47 minutes ago, Pat Stanford said:

Due to the way the data is stored in the Wide Flange (and I am assuming all of the other structural objects), it is going to be very difficult, possibly impossible, to get a data tag to extract the services and size information.

The Wide Flange has 14 different series of steel, it stores the size for each of those series in a different field, so to get the current size you have to know which series number to look in. But the series is stored as an integer. So to get the size you then have to concatenate the field name together. I can do this fairly easily with a script. I have not been able to make it work in a data tag.

If you know you will always be using the same series of steel, I can give you the field names to get the size for that series. I can probably even give you the ability to have an extra field that will tell you when the Series of the steel object (and therefore the size is incorrect) does not match with what the data tag is expecting.

But you would need to have a different data tag for each Series of steel, and possibly for each profile also. I have not even started looking into how to get the data tag to look at different record formats to handle the different shapes.

Overall, a very useful request, but quite hard to do.

My suggestion is that you put in an enhancement request to add extra fields to all of the structural shape objects that will contain the current Series and the current size that the object is being drawn. Then it would be easy to generate a shape specific data tag and probably possible to generate a data tag that would handle multiple shapes.

Pat - thank you for looking into this - I'm glad asked for help before falling in that rabbit hole. I will submit an enhancement request.

I have an alternate idea I have for representing this information but could use your help.

Concept:

Make each member a symbol (which I've already done) and name the symbol - for instance - Walk Way Support W27x94 @ 65'-6"

Create a worksheet showing those symbols names, image and qty.

Use Date Visualization to color each symbol differently.

Help needed:

I can get it to summarize symbols in my worksheet but don't know how to

A. include QTY of symbols in drawing

B. restrict worksheet to only the symbols I care to display (perhaps by choosing only one class to include in worksheet)

Any pointers you can give on making that work would be great. Just yesterday I learned how to make a window worksheet and I'm playing with other types of symbols now. Fun stuff!!!

-

24 minutes ago, Pat Stanford said:

What tool are you using to draw your steel members? If more than one, please attach a sample file with an example of each type of object, preferably in two sizes so I can see what fields are different.

Thanks Pat -

I'm trying to shave off time from my documentation by using smarter modeling. This model uses 3D angles, round tube and I beams. I also just started reading that there may be a way to put the items in a worksheet if each are symbols with their symbol image, type, weight and length. I have a feeling the project with keep changing and having a ready to go schedule of parts would be amazing and save me lots of manual work. Attaching a sampling.

-

I found this but still cant figure out what I'm doing!

-

Hi All -

I'm new to tags and trying to use them to display info about two things -

1) Finishes. If I've created a wall and given it a material there are finishes embedded. I'd like to be able to create a label or call out with leader line with finish info for that wall generated by the material. Is this possible? It would save so much typing and ensure accuracy.

2) Steel Members. I'd like to have a label as a call out and leader line that will draw from the type of profile used to create the 3D steel unit, such as W27x94.

thanks!

-

6 minutes ago, Pat Stanford said:

@Tom W. Please explain the Analysis method. I played with the analysis tool and could not figure out how to make it do what you are showing.

I just tried.

• Extract top face

• Lower to desired level

• Click Analysis Tool in First Mode

• Click on Extracted Face

• Click on Main Object

• Delete Extracted Face to Reveal Path.

not bad!!!

-

1 hour ago, twk said:

Care to share just the model portion of the file? Willing to have a crack at it as well. What about converting it to subdivision and using the split mode?

I wasn't able to convert to subdivision. I guess its harmless enough to post this piece.

Thanks for looking!

-

3 hours ago, Pat Stanford said:

There may be a better way, but I made something that I think works. There are a lot of destructive steps in doing this, so make sure you have backups and make copies of objects. I like to work on differently layers and inside of group to minimize the things I need to look at. I also like to move things a fixed distance so I don't accidentally snap to other objects. Here is what I did:

Duplicate the "wall"

Go to a Front View

Move the wall up 20' in the Y direction (or however far you need to be out of the working space of the other objects in the drawing.

I moved this to a different layer, but that was just my preference.

Use the Extract tool and extract the Surfaces of the top of the wall. I think I ended up with a group of 22 Nurbs Surfaces.

Enter the group, select all, and Add Solids. This gave me a single very think Solid Addition the shape of the top of the wall.

Edit the Group and Ungroup to get the single solid addition sitting at the top of the wall.

Go to Front View and Move the thin down 6" (or however far you need to be from the top)

Duplicate the this Solid addition so you have as many of them as you have different pieces of wall.

Select a section of Wall and a copy of the thin and Intersect Solids. Repeat with the other sections of wall and copies of thins.

You should now have a number of solid intersections that represent the "section" of the wall 6" from the top.

Extract the Curves for the side of the wall you need.

Enter the Group.

Select All

Compose. When I did this I think I ended up with 5 NURBS curves.

Zoom way in (700,000%) and use the Reshape tool to move the end points of the curves so they are coincident.

Compose the sections. Repeat until you have a single NURBS Curve.

Exit Group

UnGroup.

Go to Front View

Move the NURBS Curve down 20'

You should now have a NURBS curve that follows the edge of the wall at 6" down from the sloping top edge.

Ask again if you need more detail. Or let me know if I can post a file with the various steps.

Its going to take me a moment to wrap my head around this!! Thank you!

-

16 hours ago, Tom W. said:

If the solid tapers inwards, can you Extract the top surface, lower it the required amount then use the Analysis Tool in first mode to create NURBS Curves on the sides of the solid where the Surface intersects it?

I haven't used the Analysis tool before. But the idea of lowering it is interesting. I even tried creating tubes with the top profile as the center of the diameter to get the line on the face but couldn't get all the shapes to subtract out to give me the lines. AHHHH.

-

1 hour ago, Pat Stanford said:

Can you post a file with the solid shape. I have a couple of ideas, but need to see your shape to figure out if they will work or not.

I really appreciate it - I will send privately as its an active project and that was just a portion as a "for instance."

drawing convert to hatch?

in General Discussion

Posted

Link so I can upvote please 🥸