Conrad Preen

-

Posts

1,023 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Conrad Preen

-

-

More info here

-

Yes it's the labels - I thought so. Nice drawing!

In pdf the arrows are clickable links so that makes navigation very easy. For paper publishing, I think what you are doing is the best that can be done and it's actually good enough. Did the nudge thing work?

Conrad

-

@hihosilvey yes we are aware of this, and we already have a fix that we are testing right now.

Thanks for reaching out!

Conrad

-

Hey @hihosilvey

That's an interesting way of doing things. Moving a load of circuits and devices to another layer would need the circuits to reset AFTER the devices. So for this workflow (if it's what you really need) I would suggest adding Select Similar to your workspace (see VW help for how to), select all the circuits and nudge them up and down (shift-arrow keys). That will make them re-detect their end points. Of course I'll add this to my notes for us to look at.

Do you know about Sheet Layers and viewports? It seems strange to me to move stuff to another Design Layer for printing. Maybe you have your reasons and I'd definitely like to know them. If it's just for printing though you can have multiple sheet layers with viewports showing different parts of the same Design Layer - perhaps that would suit you better?

Conrad

-

Hi @hihosilvey

Sorry if this sounds a bit facetious, but... what about using All Layers Cable Report?

There's nothing special about ConnectCAD Cable report commands. They do exactly the same thing as the Create Report command but with only one click.

Just to get a better understanding of layer-to-layer connections. The convention we use is that the layer of the source end of a circuit is the Circuit's layer. That way we don't get duplicate entries in an all layer report. You can see this in the Object Info Palette if you select the destination end of an arrow circuit coming from another layer.

Hope I've been able to clear that up and do reach out if you need any help.

Conrad

-

Well what Niko suggested was just a workaround ...

It seems to me that there's a more fundamental point here. The reason for using ConnectCAD is to save designers time. That's what your boss is paying for - productivity.

Yes we like you to be able to customise the look of our software, but it is also vital that ConnectCAD "just works" out of the box without a ton of fiddly clicks. The experience for the new user is very important. It's so easy to get hung up on the details and forget the big picture.

Giving you the ability to disappear this text is on my list, please be patient. We need to do this the right way.

Conrad

-

3

3

-

-

Hi Jan,

Funny, I thought I had replied to you about this. You are running up against a limitation of the Vectorworks database itself. And yes, one of my projects is to improve this but the right way is not to work around but to address the fundamental issue. Our Circuit object in effect does the database JOIN that you are looking for.

From what you say

On 2/9/2021 at 12:09 AM, Jan Sander said:In the end I would like to have a cable that has e.g.:

cable name

cable type

signal format

socket name

cable length on it.

All that information is in the Circuit object already so you extract it as a report or use our Make Cable Labels command to create a worksheet that you can export to Excel for example. You could probably parse the JOINed table which is a Circuit report and factor it back into Devices, Sockets and Circuits in an external relational database for yet mare flexible reports.

That's all I can suggest for the current version.

Conrad

-

@aruk I'm not able to reproduce that gray square here (Mac OS 10.15.7 Vectorworks 2021 SP2) by the way. If you want me to investigate further please PM me the file and show me exactly where to look.

Conrad

-

Is the gray square part of the problem or did you draw it?

Conrad

-

Hi Shane @Shane Smith

You just drag the Equipment Item over a Rack Frame slot and drop it. It resizes automatically to fit the slot. It's kind of too easy.

If anything doesn't work for you let me know.

Conrad

-

Hi @cessnaflyer

What would be really useful at this point would be for you to PM me one of your Vectorworks files so I can evaluate. BTW are a you a Beta Tester?

Conrad

-

@switchonet I have bug-listed your point. We'll see what we can do in an upcoming version.

Can I ask you and everyone to take the trouble to start a new topic each time? Forums have tons of info but lousy search and no organisation. A relevant title is your key to getting noticed. This issue nearly fell off the planet FYI

Conrad

-

1

1

-

-

Hi Ean,

You should be able to do this using the classes Sys-CircuitNumbers etc. If you create a text style and assign it to the class you can also change the font. No guarantees about changing the arrow lengths to fit every possible permutation.

I feel that there is a danger of going overboard with customisation. The main goal of ConnectCAD is to save you time and increase accuracy. It would nice if the world would agree a limited number of drawing standards that we could support and be done with it.

Conrad

-

Use a rack frame! That's what everyone does.

Conrad

-

Hey everyone!

This thread is drifting off-topic in a major way. Forums (or is the plural fora?) are notorious for being full of useful info that nobody can find.

This thread is for useful nuggets of information, how-to's etc. If you have something to contribute great. If you have a question start a new thread with a useful title.

Conrad

-

1

1

-

-

Hi Jan,

Are you reading my list of future projects by any chance? If I understand correctly you are looking for a socket report showing what's connected to that socket - right? Vector database is not able to do this - yet...

1 hour ago, Jan Sander said:is there any way to disable that socket name is automatically written into the tag as long as both names are the same?

No there isn't. I would not like to add this kind of setting unless there is a really compelling case for it. We have to fight the tendency to add complexity to the interface. The software itself should detect the right thing to do and just work.

Conrad

-

Hi Jan and others,

The basic problem with trying to create devices given a cable list is that you have very limited information about the devices. Yes the cable list contains the details of each socket that is connected but there are no other clues. So this command is fighting a losing battle. A bit like the reverse engineering task which I designed it for so many years ago. I think the old Make Devices from List should retire and make way for a new workflow.

Let me share my thinking with you.:

- We begin with a cable list.

- A few quick spreadsheet maneuvers extracts a list of all the device names.

- You add the Make and Model for each device in the list.

- Name, Make and Model go into a command that automates the Device Builder and puts the devices on the drawing.

- You shuffle the devices into a reasonable layout

- Connect them up using Make Connections from List

It isn't a magic "design my system" button. of course. You still have to intervene but it would be a lot faster than manually drawing everything. Obviously if a device type isn't in the Device Builder database you would have to add it. But you only have to do that once.

It would be interesting to hear your views.

Conrad

-

Hi Matthew,

Working on a 4mm grid is your safest bet.

Conrad

-

1

1

-

-

Hi Ross,

You can force the signal type to be whatever you like by entering the signal type in the Object Info Palette when a circuit is selected. Signal type is only calculated when the circuit is placed or moved so it becomes reconnected. So that takes care of it in practical terms I think.

Having the software "know" which signal types are compatible is a bigger step than it might at first seem. It could introduce complexity. Always worth thinking about though.

Thanks!

Conrad

-

1

1

-

-

1 hour ago, SamWilliams said:

Sometimes you may draw a connection backwards, how do we flip this cable direction?

@SamWilliams looks like you are reading my things to consider list... I have been thinking about that one. It's weirdly harder to implement than you would think. But it's still on my list 🙂

1 hour ago, SamWilliams said:Do we have a method of selecting a set of arrow connections and adjusting the length so that they all align? (this is currently quite painful). Especially if you take sometihng in or out of a rack etc and it resets everything (or some of the cables) that you previously aligned.

That's going on my list.

1 hour ago, SamWilliams said:Also when selecting large numbers of arrow connections on a single page it will highlight all devices but will sometimes detatch arrow connections or datatags which would normally move relatively with the device. (Annoyingly its not always that this happens).

This is a question of getting a reproducible case. Thanks for the heads-up

Conrad

-

Ah now I understand.

The Device Builder wants you to set a Make and Model so it can save the device in the user folder database. That way you only have to create it once. It also gets saved as a symbol in the Resource Manager. If it's a physical device then you will need to add the dimensions too. But of course there are times when you just want to create a one-off and that's why we also have the Temporary Device button.

Sounds like we need a bit of clever highlighting to guide people to the next step in that dialog.

Location is fixed in the OIP because the Equipment Item object updates this every time you move it. Tell me a bit more about the workflow you have in mind.

Conrad

-

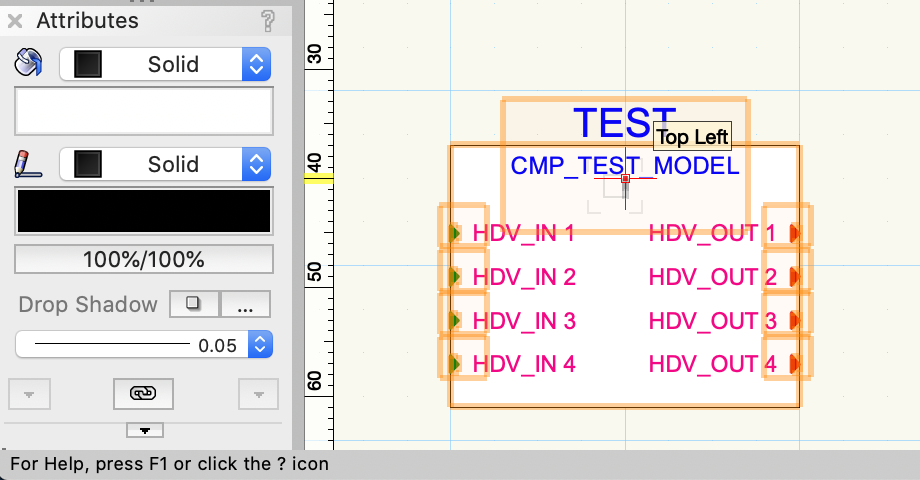

@JonnyAVC In reverse order...

Device Builder uses the fill set in the attributes palette.

Virtual devices: the difference between virtual devices and physical devices is that physical devices have non-zero dimensions and as such no Equipment Item is created when you do Update Rack Elevation. The point of having virtual devices as a concept is that these days these things exist as say processes in a server.

13 minutes ago, JonnyAVC said:I am also having to create virtual devices over physical devices

Not really sure what you mean here. So if I haven't clarified it let me know.

14 minutes ago, JonnyAVC said:default "Label Symbol" -

Noted !!!

15 minutes ago, JonnyAVC said:Any idea on time frame?

"Soon" is all I'm allowed to say right now.

Cpnrad

-

@Ljones Ah wait! We do not release software without testing but we also can't predict every eventuality. This particular snag is an unintended consequence of an honest attempt to help users other than yourself who want to be able to draw schematics at any scale. Rest assured that we are working very hard right now to please everyone!

Conrad

-

1

1

-

-

Yes, I get it. Rack or cabinet.

Connect CAD 2021 Workflow

in ConnectCAD

Posted

Ok, we'll have a look at it . Thanks for letting me know.

Conrad