CETLV

-

Posts

102 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by CETLV

-

-

Wesley, you can message me and I can provide you some very good resources on max seating arrangements.

-

Good day, 14 seats is just fine as a starting point. However the vast majority of the codes read is that you cannot have any more than 30' to an exit row (think standing in the center of a 60' aisle, you have 30' to the choice of 2). Here in LV we have what are considered to be the strictest fire codes in the country and I have not had one single floor plan kicked back from any out of town show in almost every state following LV codes. Using this length, to maximize seating with headstrong clients you CAN do a 50+ft aisle, but you cannot exceed 30 ft to any egress path. Also, keep in mind that the width of the row path (from the back of the seat in front of you to the front of your seat) starts at 12" and opens by .3" per chair added over 14. So by using the standard 18" row path, you are basically covered for seating sections of 50+ ft never to exceed 60. if you actually do push it to 60' youll need a 20" aisle, but I recommend a 22" aisle. I can only imagine that most just do it so they never run into an issue. The thing to always keep in mind with seating of these widths is that the aisle widths usually need to go beyond 6ft to accommodate the funneling of people from each section. The simplest way to do this is to calculate all people that will be funneling into that area and do the standard .2" PP calc.

Wesley this is a fine resource, however you have to know that Clark County actually governs the Fire Codes, so you should be looking at http://www.clarkcountynv.gov/building/fire-prevention/Pages/FireCode.aspx for your info.

The 6ft rounds of ten indeed need to be placed on 12' centers, however you CAN nest them provided the occupancy does not exceed linear exit space. To nest tables successfully, take your tables, place a 12' diameter circle, draw a 6' radius line from the center to the edge, then draw a line straight down from the middle point of that line down until it hits the diameter line of the 12' circle, this is as close as you can nest them. (Assuming 18" chairs of course) Regardless of how you distribute the tables, you must have a minimum of 3' aisle from chair to chair. This does NOT change if the width of the table changes, you still must have 3ft. So a 5ft rd, IS permissible to have on an 11ft center, again, assuming the 18" chair. If you do not have chairs (ie high boys, cocktail tables) you still have to maintain the 3ft aisle. This rule of thumb basically applies to anything involving rounds to anything, other chairs, tables, walls, banquet setups, bars, you get the drift. Needless to say that Clark County has really buckled down on these regs since the mandalay bay shooting. Lots of egress problems there... message me if you want some more info.

And don't forget to keep those fire extinguishers clear!

Love this thread and I would love to hear about stories about other fire marshals, they can be rough, even when they are wrong! :-)

On 12/27/2017 at 7:52 AM, Wesley Burrows said:Thanks for sharing your workflows and experiences. I find it very insightful! From a code standpoint, (USA based)

I too have often found the 14-16 seats (size dependent) to be max in a row to meet this IFC requirement:

"Aisle accessway travel distance - The maximum length of travel along the aisle accessway shall not exceed 30 feet (9144mm) from any seat to the point where a person has a choice of two or more paths of egress travel to separate exits. (IFC 1017.4.3)"

I rarely run in to any client/producer, etc, pushback on that from a theatre seating standpoint. I do however run in to pushback on seating for banquet rounds. Does anyone have any sources for code (I know it varies somewhat by municipalities) regarding rounds?

I usually use this as a reference:

https://www.lasvegasnevada.gov/cs/groups/public/documents/document/dhn0/mdax/~edisp/tst001962.pdf (I live in Kansas City, and we do events all over the US, but this seemed like a good starting point)

For rounds, we are usually seating 72" rounds of ten, and that document shows ~6' table edge to edge if any seat is back to back, which is typical in a round configuration. So I usually start my round layouts @ 12' centers. Then people want to try 11', 10' etc, to squeeze more people in. I know that a lot of places will set this way, without saying a word, but if the fire-marshall gets a wild hair and wants to shut it down he could.

Does anyone have any clear sources that either give me a leg to stand on @ 6' edge to edge, or somewhere that shows that 4' or 5' edge to edge is ok in certain circumstances? Or just general best practices that are a good starting place for code compliancy.

-W

-

1

1

-

-

Vectorworks peeps, I am really liking the advancements in the Braceworks functionality, however I do have one suggestion for a feature that I would like several to chime in on. I know when we put a truss and motor up, it calculates loads at the hook, but is there a feature in the works to be able to design a grid with points? Or beams with distributed loads across lbs per ft? I would like to create a layer with beams, and or hook ins in ballroom ceilings then know where I stand on a total ceiling load on the entire ceiling (I know I can just add it up, but just a suggestion) and loads on certain beams, hook ins, ribbon grids, fly rails, etc. Is there anything in the works for this in addition to the ground support and bridle functions? I do a LOT of work here in LV and end up designing far different rigging systems using the same exact set of points all the time.

-

1

1

-

-

3 minutes ago, scottmoore said:

And to further that, I might assume that any company forwarding that information, regardless of it’s accuracy, is opening itself to liability concerns from a legal standpoint.

well, now that I think more about it, that info IS the info they would have to stand behind in a lawsuit anyways, so they should be confident in their numbers, but there is a lot to be desired for a customer using the wrong model cross section, for light duty vs heavy duty models. If they use the heavy duty numbers, and get the OK in Braceworks, then actually rig light duty and it fails, then thats what they are likely thinking. However someone who is serious enough about rigging knowledge to pay 5 grand for a license you would hope wouldnt be so negligent...

-

Perhaps they believe that people are going to rely on the software and despite any "disclaimer" they are not going to get out the calculator and do the actual math!

-

Well, its hard to say. I design for different manufacturers all the time depending on who the house rents from. One of the most common ones I have seen lately is XSF. Its just sort of a bummer that braceworks is essentially useless with its math unless you get very specific data. I am also curious about the chain cross sections in the hoists. rigid seems like itll work just fine, however not all chain has the same details. but i mean if a chain fails before other components, you failed math in first grade.

I am indeed a SS guy, so I will keep a lookout.

-

Has there been any updates on this? I am still searching for accurate cross section info. on a multitude of manufacturers.

-

I have to say, SP2 really helped a lot of the bugs out. However I am curious about the hoist chain cross section only having a fibercore option set available and not typical chain used with hoists? My rigging numbers were off significantly because most of the truss symbols do not have cross sections added to them as of yet, and by default are Rigid, (which can really mess you up if you dont pay attention) Does a Rigid chain cross section do the same?

-

Fantastic response to this question, thank you all!

-

Oh thanks! Much appreciated!

-

Hey thanks for responding. I do know about the border tools. Thats what I do now, but I was hoping to see a top finish style that is more of a bunting style that has a sewn in tie back. Its not that its a huge thing, I was just wondering if anyone had a better method. More or less just me being lazy and wanting a "skirt the stage button" :-)

-

Anyone have a good workflow for easy stage skirting? I would think that perhaps they would have just a "skirt stage" button on the creation tool. I just get annoyed with having to alter the heights, set the top finishes, and mess with all the pleat settings for a lot of custom stages. If its a square its easy enough, but its still sort of a pain. Anyone have any good tips?

-

Fantastic! Good to hear. Thanks for the update!

-

Does anyone know if its possible to say drop a 6 way corner block into an already existing run of truss without breaking connections?

-

Good day, I played around with this for a while and didnt see how to do it. When using the insert truss tool in braceworks, is there a quick way to scroll through different truss types and keep the command active to connect a new piece? I keep finding myself having to go to the truss symbol menu at the top of the window, and manually selecting a new truss piece from the library. I seem to remember seeing this shortcut in the video that introduced it, but I cannot find it.

Thanks all!

-

VW 2018 Designer W/ VSS and one year of Braceworks. Offers?

-

hey I was wondering if anyone had any input on files that are done of stage lines... I need to put up a mobile stage and just did not feel like building it from scratch. I have already submitted requests to stage line, and I guess I dont speak enough french.

-

Thanks!! ill figure it out!

-

I am also having an issue. I installed the demo version, and I dont have any of the "Vision" menus in VWX, so basically I cannot figure out how to export the vision files... I know how to edit the data, but cannot export the file.

-

22 minutes ago, Rob Books said:

Soem of the Vision Items have been moved to the Object Info pallet, you will need to select fixtures for that part. other items have been moved to the Spotlight Menu, Visualization group.

there is also a vision specific section of the forum where you might get answers quicker than the general troubleshooting.

Rob.

Thank you for your help, however without the vision menu how can you export the vision file?

-

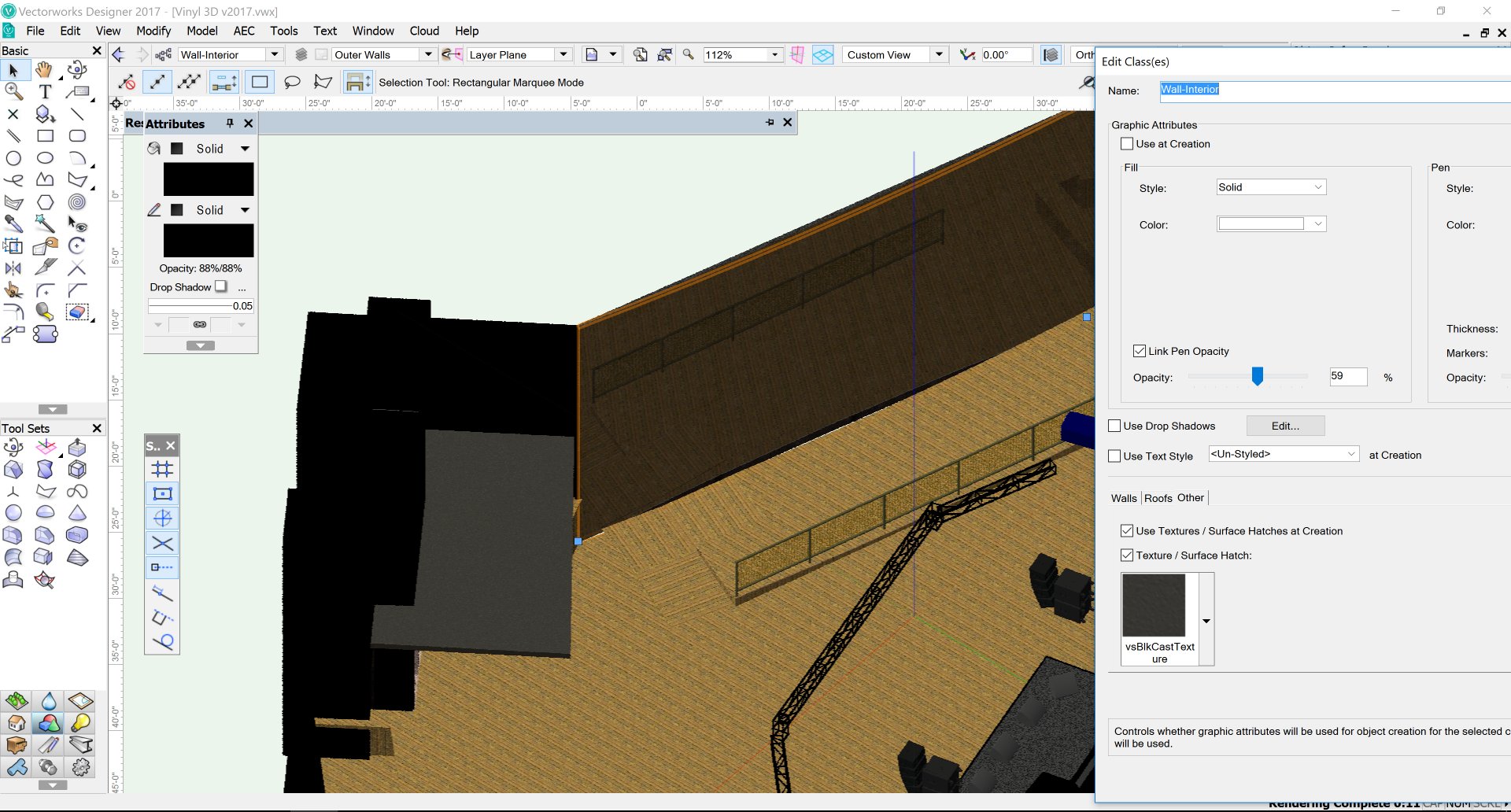

Hey, I am running VWX 2017 designer and have just installed vision 2017 demo. I cannot get the "Vision" menu to show up in VWX at all in order to compile my vision file.

Does anyone know what I may be doing wrong?

Thanks in advance.

B

-

Well, honestly I do not know what happened whatsoever... I just got a new system, so when I reinstalled I forgot to up my undo amount, so I could not undo back past it...

However, all was not lost, the wall shape was still very much in tact, and it was obviously the outer walls of the structure, so all I had to do was simply redraw a new wall around the perimeter and done, but it was just such a strange occurrence. The actual roof segment you are correct is not a roof symbol, but an extrude which in my case works for me since I simply need flat with steel beams.

I still cannot figure out how the round wall had mirror properties however, the problem literally fixed itself and I have not been able to re create it since.

Thanks all!

-

This Problem has basically fixed itself... so I am thinking it was a software Quirk....

HOWEVER, I have a new problem with this.... I drew an extruded polygon over the exterior walls, and went to create a roof, but noticed that I didnt have a flat roof option, so I was just going to go with an extruded polygon simply with black paint. However somehow all the outer walls became a roof, and the walls all dissappeared... any ideas how to get that back?

-

Atomic Design - Hive Panels

in Entertainment

Posted

I made this conversion in DWG, you can import it and it may work ok. Note: I work in 1:1 all the time to make cross platforming easier, so you may have to scale it.

Its an upgrade since anything from atomic will be all wireframe with no meshes anyways.

hive 3d solid.dwg