mike m oz

-

Posts

4,876 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by mike m oz

-

-

7 hours ago, Matt Panzer said:

Thanks for mentioning these. We are looking to address these issues and these are some of the ideas being looked at.

Possible that some users will want shims between butting units to replicate the real life scenario of adjusting units so they are vertical. Likely that would be the same width as the jamb to wall shims. Thus maybe separate shim thickness are needed for wall jambs and butting jambs.

-

1

1

-

-

Matt,

One way around the problem would be to have user defined shim gaps for each edge.

A better way would be for butting shim gaps to automatically set themselves to zero when units are butted up again each other.-

1

1

-

-

Whilst the 'author' might understand what is going on with complex sections like those proposed, will the contractor, subcontractors and tradesmen understand it. The risk is them not understanding it and errors occurring on site. The resulting argy bargy about who is responsible and who is going to pay to fix the mistakes is territory best avoided.

-

3

3

-

-

Zoomer, you can do all of your first three with the custom configuration of the Window tool.

The last one you can do with the Door and Window tools. The only issue appears to be the Wall break line that shows in Plan View when you have shim gaps. Set the shim gaps to zero and there is no Wall break line in Plan View.-

1

1

-

-

Zoomer, can you please provide elevation views of what you need.

-

- Popular Post

- Popular Post

Window tool:

- Click on the Settings button and in the General Pane select Custom Configuration.

- Edit the Custom Configuration to define your number of columns.

- Define the window type for each cell.Windoor tool:

- Click on the Form button.

- Create two horizontal cells.- Select which casement type you want in each cell.

-

5

5

-

Windoor doesn't do curved windows.

-

6 hours ago, edwardskeegan said:

I have a rectangle that I'm simply trying to turn into a rectangular prism

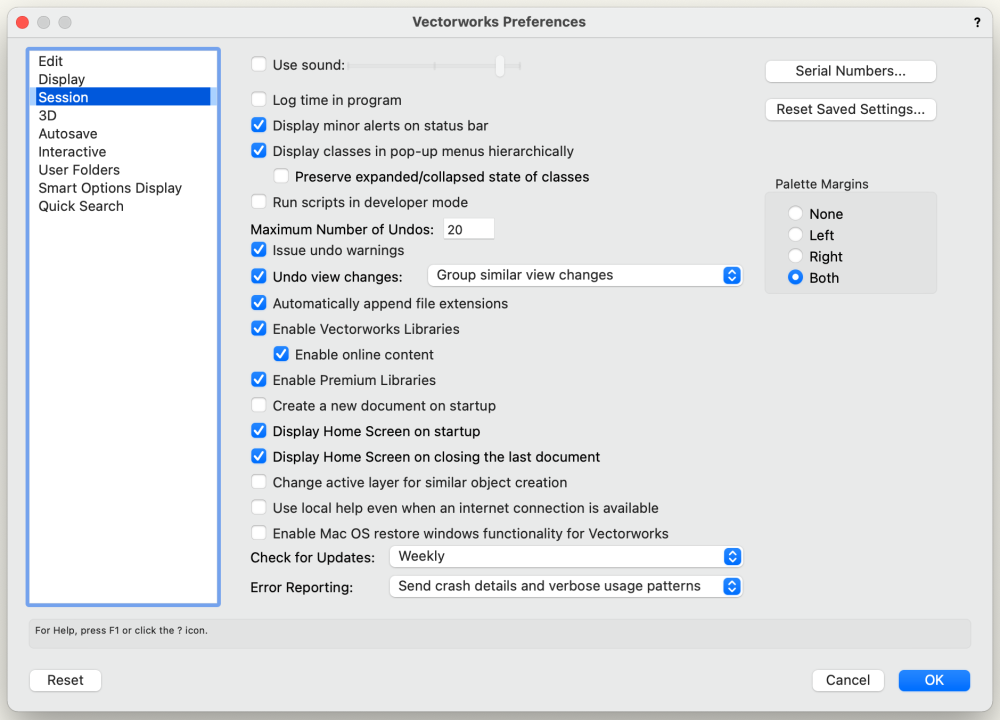

If you want to taper to a single point use the menu command Tapered Extrude (Model menu) and enter the taper angle you want.

If you want to taper to a single line top edge then draw a line where you want that to be, then select the line and rectangle and use the menu command Multiple Extrude (Model menu) and give it the height you want.

There are other ways to do both, but these are the simplest way to do it.

-

It isn't just about showing the client the design. They need to be able to explore and understand what their project will be like.

Thus we need to be able to give a client a 3D model of the building and the site that they can easily navigate around.

-

It isn't just about showing the client the design. They need to be able to explore and understand what their project will be like.

Thus we need to be able to give a client a 3D model of the building and the site that they can easily navigate around.

-

1

1

-

-

56 minutes ago, AlanW said:

Hi you interested in getting the VR experience for your Client??

Yes.

-

57 minutes ago, VIRTUALENVIRONS said:

that most Vectorworks users are still 2D oriented

The architecture paradigm is rapidly changing and those that don't start working in 3D will end up being marginalised.

-

1

1

-

-

I have a client who is having difficulty with the PC Navigation.

Advice on how to get them a better experience would be greatly appreciated.

-

Jeff, if you rule out everything obvious then please submit a bug report:

https://www.vectorworks.net/support/bugsubmit-

1

1

-

-

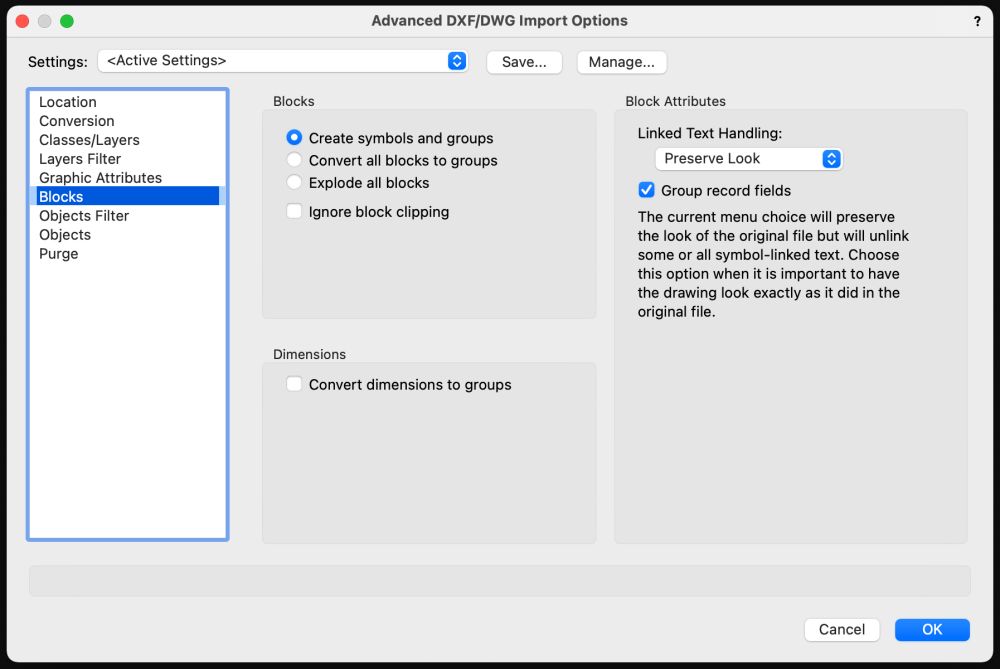

Jeff, I would check that it isn't an exploded DWG.

-

What version of Vw and which SP are you using? Also which OS?

-

-

A structural engineer will be able to give you appropriate advice on the three parts and connections between them.

-

1

1

-

-

-

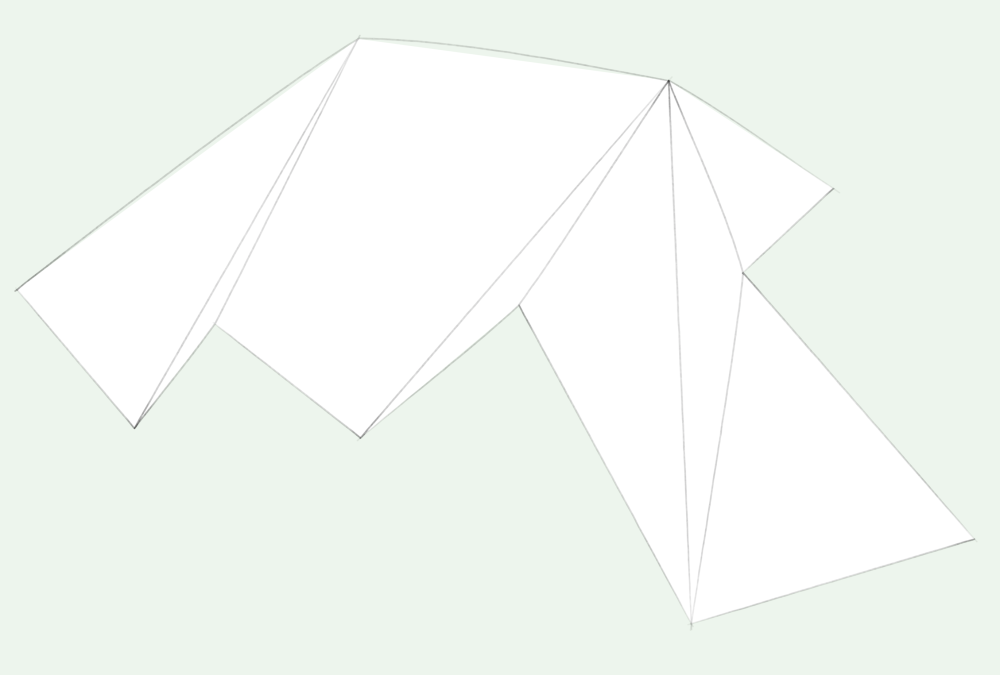

3D polygons are planar so need to have only three vertices. You need to either raise the 3D polygon ends in the centre of the image so they finish on the edge of the 3D polygon on the right or break the latter up into smaller triangles that join at the lower common point.

-

Have you tried to find a suitable one at Sketchup Warehouse? If you find a suitable one you can import it into Vectorworks.

Alternatively provide a sketch of what you want so it can be modelled.

-

-

The Cabinet tools are scheduled to be improved.

https://www.vectorworks.net/en-AU/public-roadmapAll too often I end up modelling cabinetwork because the existing Cabinet PIO capabilities can't get me close enough to what I need.

-

Kudos to the engineers responsible for the Mitre Roof Face Join capability.

-

3

3

-

How to create a curved bench seat with vertical batten array back rest

in General Discussion

Posted

Model it how you think it would be built.

If all the battens need to be the same size and shape try using Duplicate along Path in Fixed Distance mode.