Mike Wright

Member-

Posts

219 -

Joined

-

Last visited

Reputation

33 GreatPersonal Information

-

Location

United Kingdom

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

-

I'm not sure if I'm missing a setting somewhere but I can't get equipment summaries to show a data visualisation on the symbol key like an instrument summary would. Is this option available? Ta VW2024 update3, windows 11

-

I had the exact same issue for SP2 VSS support were unable to resolve the issue, I had to do a clean install using the latest installer (I backed up my user files first) I now have the problem with SP2.1

-

Hi. As the title says. Used the curved truss tool. Selected the correct cross section information for braceworks but when I calc the system it shows the truss as having no weight. If I enter the kg/m in the oip it just jumps back to zero Is this a bug or am I doing something wrong? VWX 23 SP5 on Windows

-

I see from other forum posts that the cable tool is another one of those deployed perhaps too early to be genuinely useful. I'll go back to powerpoint 🙂

-

I'm also struggling with the cable tool. If I try to draw a multi cable along a path it draws the route from the distro direct to the breakout distro object then back along the path and places the connector symbol at the start of that path. Sometimes when I've drawn a cable it just ends up being a NURBS curve and not a cable. Reshaping cables seems to be extremely random and snaps to random points especially when there is a NURBS point on it no matter what vertex mode I am using. I'm attempting to learn how to use the tool and although just beginning, I can't attribute these behaviours purely to lack of experience. VWX 2023 SP3 on Windows 10

-

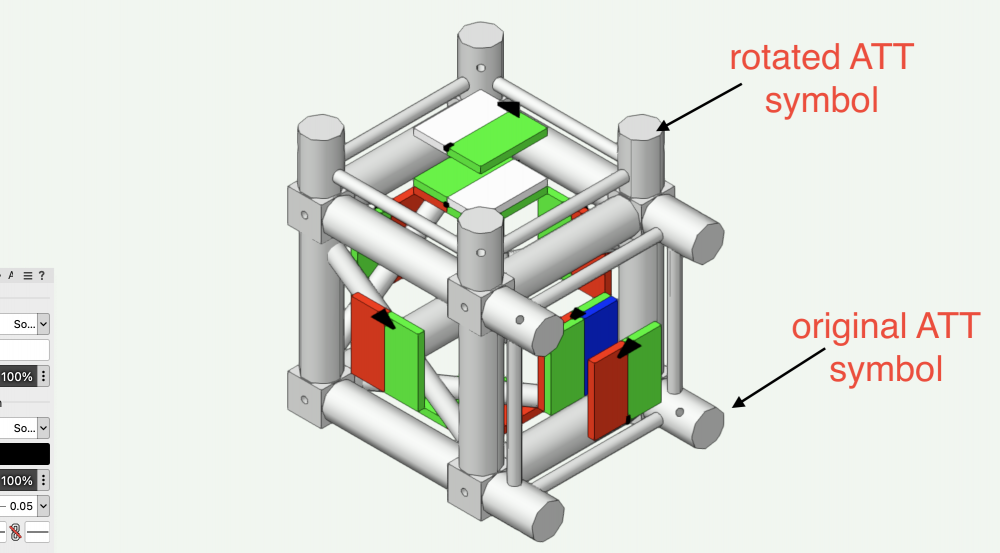

Thanks. New to truss magnets. Perhaps you can clear up a resultant query from the fix above? I've set the magnets on a box corner to be gendered so that when I attach the ATT spacers they always sit in the correct orientation. However, if I add the ATT to the top face of the box corner it creates a new symbol for the rotated ATT which does not have the same gendered magnet properties. See below:

-

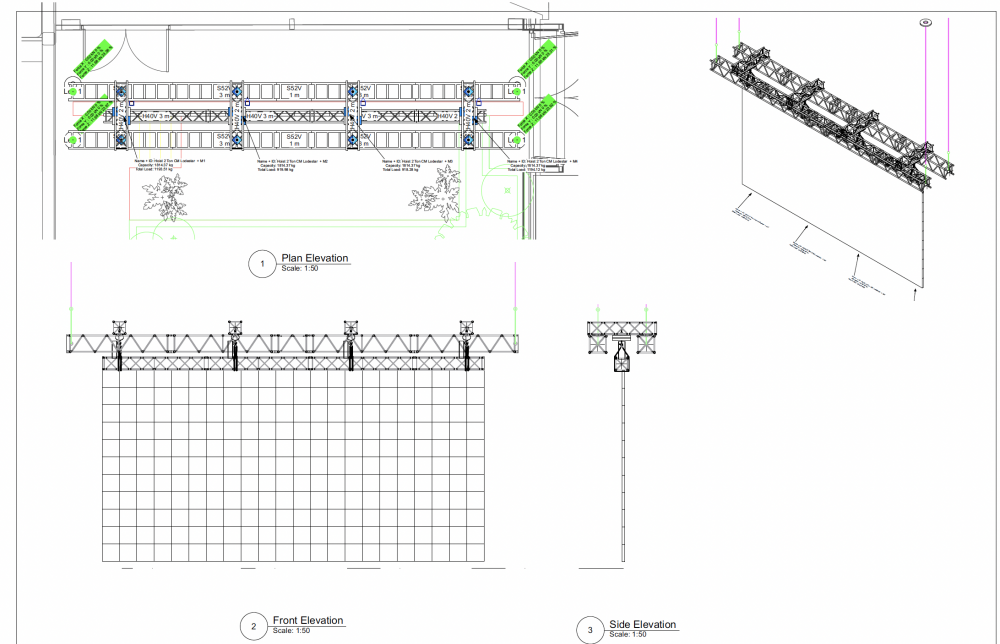

I've just worked on a project which involved a moderately complicated indoor truss structure supporting an LED screen. I worked with the project manager to choose the correct truss products, spans and hoist types. My resulting braceworks report indicated that none of the trusses were above 50% of their load limit even after applying chain shortening to account for the rigid nature of the LED screen. The venue asked that a ticketed rigger look over the loads involved, a perfectly reasonable request. Their default was to look at the weights and check them against the manufacturers load table. The configuration was as near as damn it 5th point loads and the table indicated that two of the trusses would be 110% of the safe load. My rig was therefore rejected. I then had a very experienced rigging engineer and another very experienced rigger look over the drawings and they were all in agreement that even before the dynamic loading factors were applied, the system was beyond or close to the edge of the capabilities of the truss. This has raised a lot of questions for me. Have I been over reliant on braceworks as a proof of concept, should the manufacturers tables have been my first point of call? Is the truss system here too complicated for braceworks to reliably calculate? Have I over stepped the abilities my moderate level of rigging experience gives me? There's a screen grab of the system below. I can't share the file at the moment but will attempt to re-produce it in a simpler form. The problematic trusses were the two larger spreaders and the end solution was to add two more of them so the load was (roughly) quartered between them. I'd be interested in peoples opinions/advice Thanks

-

That's sorted it thanks. It's not an option I've ever used though so perhaps it is default on by mistake?

-

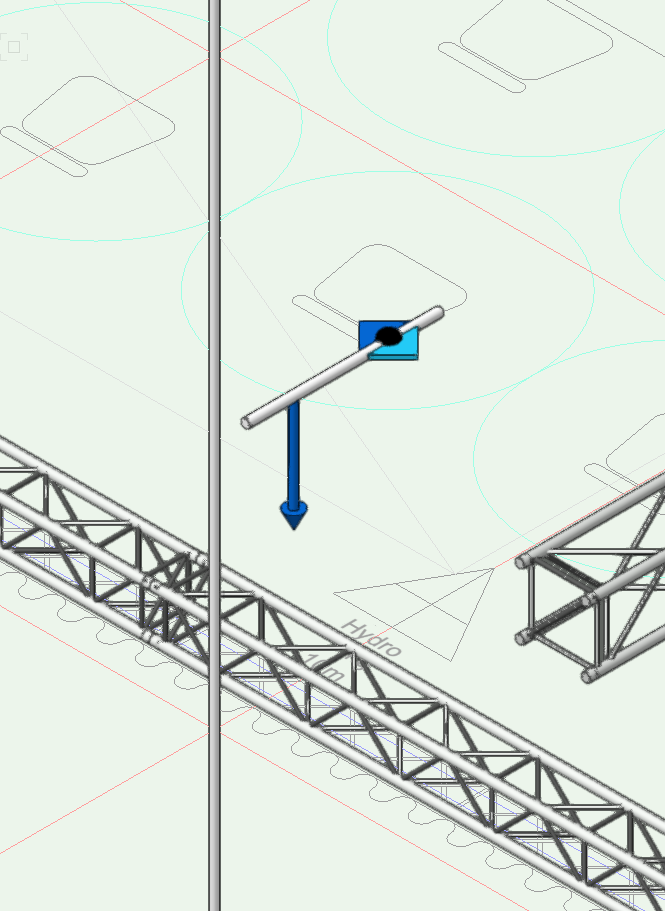

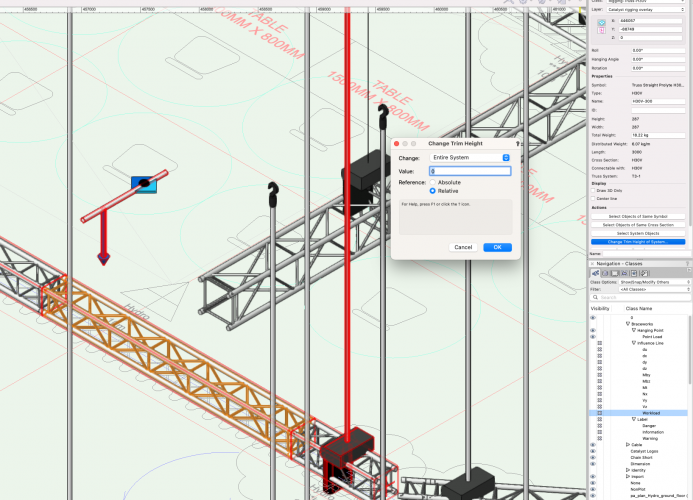

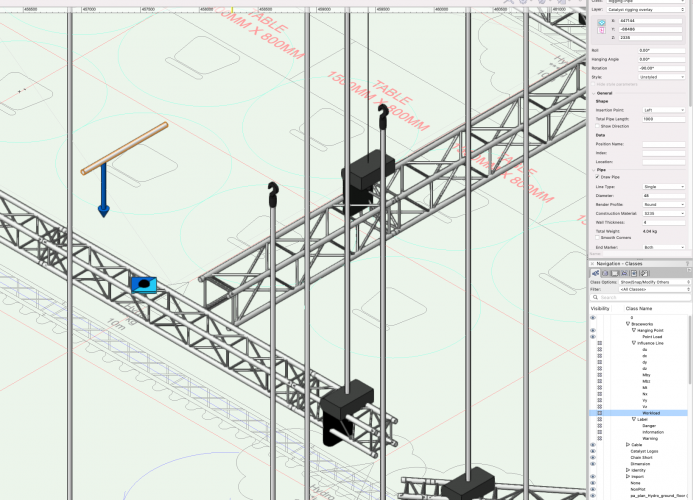

Hi I'm coming across the same problem here. If I use the insert connection tool to add a pipe, it draws the pipe and connection at a different height (in the picture below the truss Z value is 0mm, it has inserted the pipe at a Z of 1835mm When you change the trim height, the connection symbol adjust to the new height but the pipe just moves up by the amount entered. See below: After the trim height is adjusted:

-

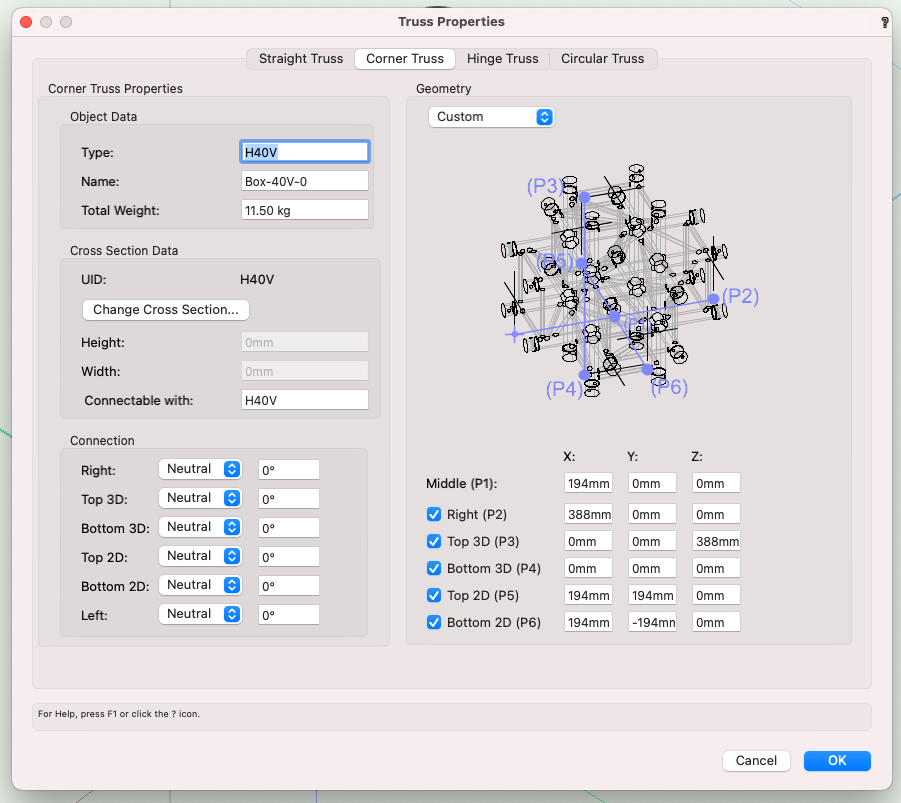

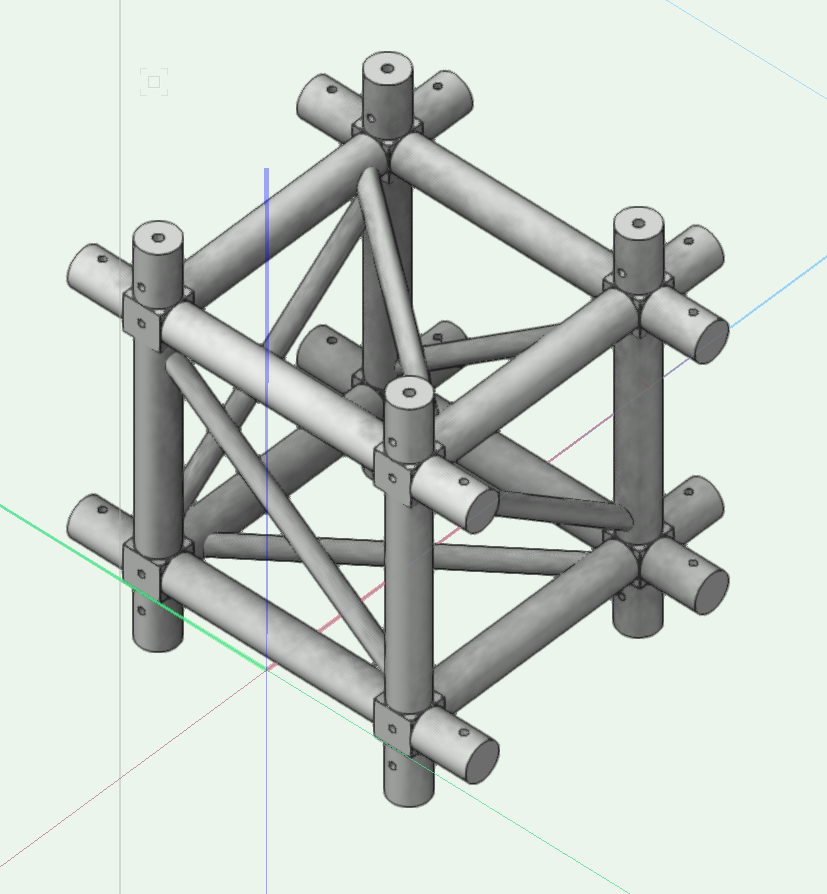

Prolyte H40V box corner - struggling to configure correctly

Mike Wright replied to Mike Wright's topic in Entertainment

Awesome! Thanks for your help. It would appear that that value is zero for all Prolyte truss in the library, I guess this doesn't matter on trusses with a value for length but will for corners like this. -

Prolyte H40V box corner - struggling to configure correctly

Mike Wright replied to Mike Wright's topic in Entertainment

Hi Justin Thanks for the quick response, file attached I'm also having problems using the same corner in braceworks if you are able to assist with that. H40V box corner try out.vwx -

I'm trying to correctly configure this box corner. I have all faces behaving as should apart from the face which is coincident with the insertion point. It will not offer this as a connection point. Pictures below show the maximum number of faces I can occupy plus the corner block settings (VW 2021 SP4.1)