-

Posts

3,799 -

Joined

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Mark Aceto

-

-

-

I can't tell if these ConnectCAD icons are actually retina, and I have no idea what the filenames should be (I can only right-click on the thumbnail to download "Unknown"):

Cable Routes definitely doesn't look Retina.

-

22 minutes ago, Nikolay Zhelyazkov said:

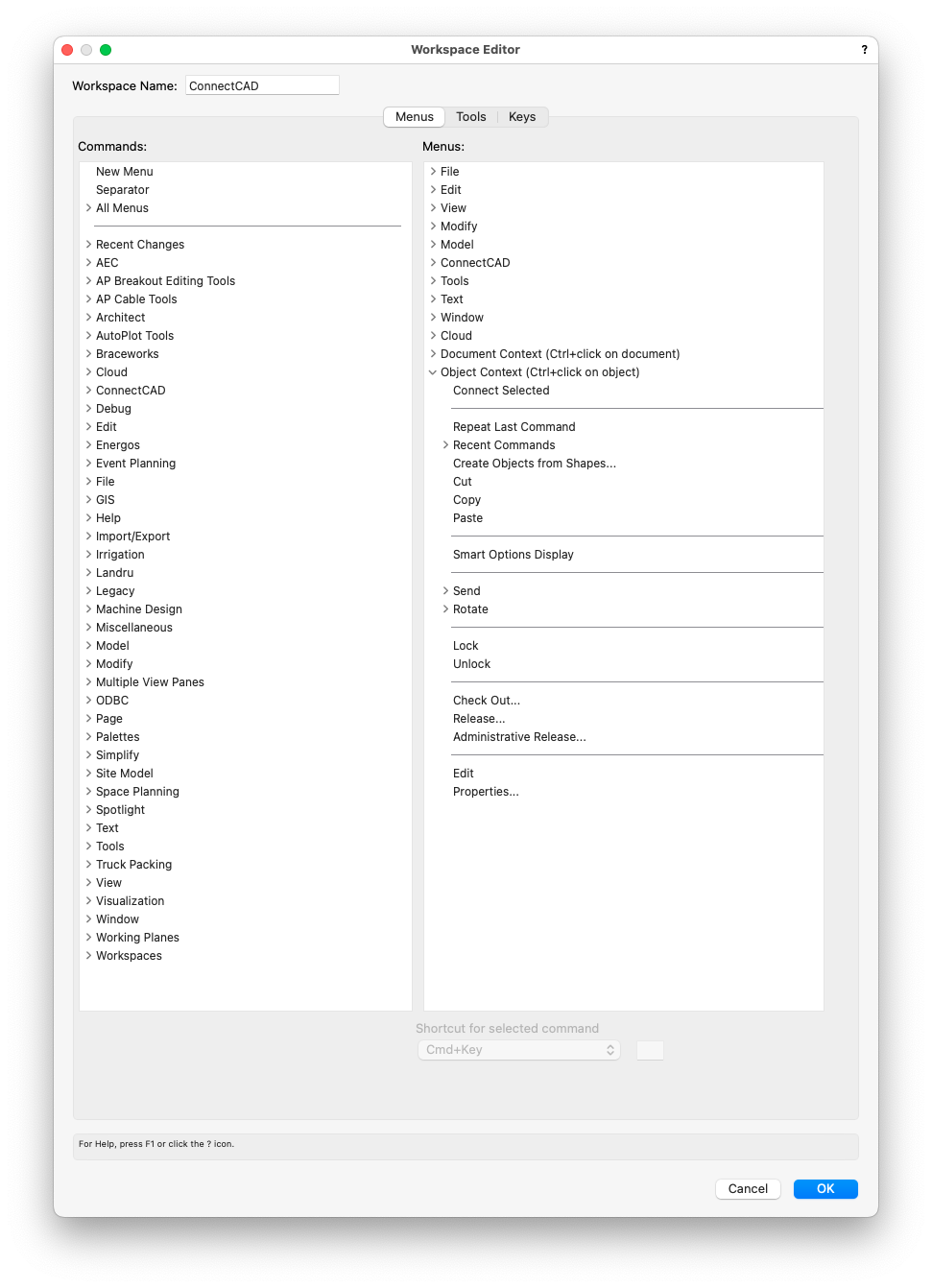

Find in report is inserted as Object Context menu:

I don't think that's what's shipping with the stock CC workspace which is why I couldn't find it in the exported text file either.

-

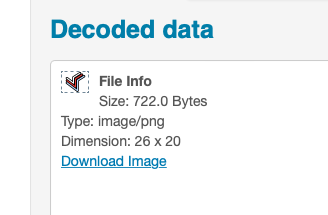

Rebuilt ConnectCAD workspace in my custom workspace but there's one leftover command that didn't have a place in the folders: "Find in Report". For some reason, it's included in the ConnectCAD folder on the left but not in the ConnectCAD menus on the right which usually means it's buried in some other menu like File, Edit, Tools... but when I export the workspace, search the text file, I can't find it.

Also, I can't move the ConnectCAD Report command once it's in the right pane. It will only stick the very bottom of the list of commands (and folders). Is that WAD?

-

-

On 10/21/2022 at 8:02 PM, C. Andrew Dunning said:

As-formatted, the lens options, no. But...with the Landru Design versions of the tools, things like tvs, projectors, and stands are chosen using the Resource Selector system, which IS Workgroup-aware.

Think we just found a chink in the armor with my plan to move from User Folder to Workgroup Library. Custom lensing isn't a dealbreaker but now I'm a little worried about what else won't be Workgroup-aware (along with Braceworks-aware and ConnectCAD-aware). VW really needs to be more self-aware.

-

1

1

-

-

5 hours ago, Projx_CA said:

Mark, I'm always reluctant to upgrade before a service pack update for the reasons you've posted in other 2023 topics - yikes!.

As an option, you can install the new version to get to know the new features until you're ready to use it in a production environment. SP 2.1 is typically *chef's kiss* sometime before the end of the year.

-

1

1

-

-

I fought with the reverse 2 leg bridle on a gig earlier this year using VW 2022. There have since been improvements to this tool that might help you out in VW 2023. I haven't tested it yet but it's worth a shot.

-

5 hours ago, jcogdell said:

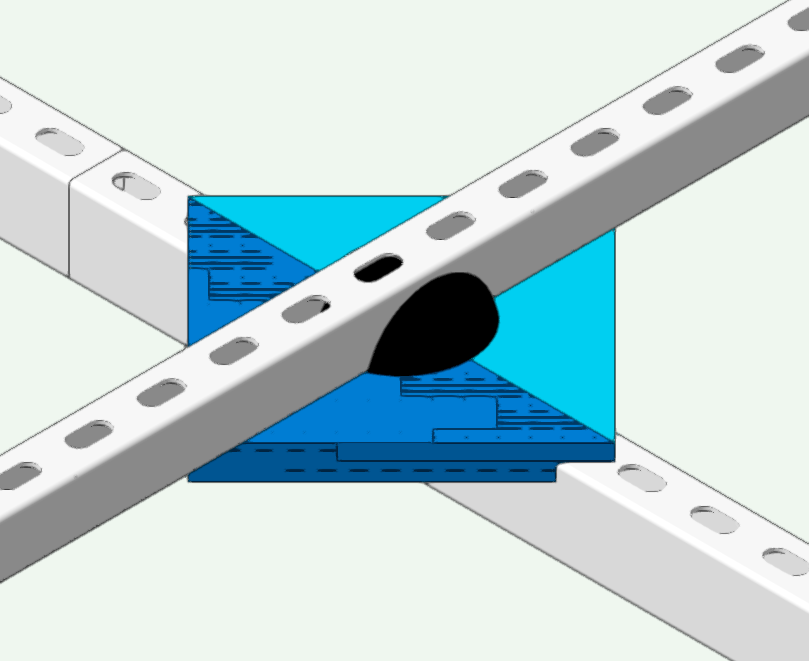

@Mark AcetoI've had a look at your file and as far as I can tell the issue is being caused by the lower layers of unistrut being too close together, I found moving them each about an inch apart stops the duplicate truss crosses being created. I've Dm'd you a fixed version of the file

Thanks, Jesse!

That makes sense. I've noticed that with any rigging elements, literally anything with a pixel (even truss cross labels) can throw off VW/BW, so that's a good note for anyone following this. Hopefully, I won't have too many 41mm strut to 41mm strut connections but I've already 2 gigs with that in the past 2 months, so...

As a solution / workaround, I'm wondering if I can create custom truss cross symbols that smaller/thinner and won't clash with each other. I guess then I would pick that symbol in the Insert Connection settings before connection any rigging objects. I thought there was a way to scale them but I can't find it.

-

On 10/14/2022 at 3:03 PM, spettitt said:

Hello, not sure if this is better in the Entertainment forum or here...

We are starting to draw video walls using the LED screen tool. We are not using Braceworks right now, but will be ASAP, and I want to establish the correct workflow in the office now ready for when we are. I would appreciate any advice you have, please.

I have a few needs:

- Be able to add header/hanging bars for video walls and have them logically associated with the panels. These are needed not only for spacial planning and build use but also for their significant self-weight in calcs. At the moment, the drawings that we need to produce pretty much daily for both clients and engineers on site show an elevation of the header configuration connected to the panels, and this is pretty much standard output for any rental company where we are. With the led screen tool, I can draw a wall and just position the header bars above it, but if I change the wall config/location/etc, it's clunky and the propensity for error is high. Much like how bumps are part of the speaker array tool, video walls need a header bar facility I think.

- Be able to attach hoists to said header bar (and thus the LED suspended as well). Sometimes we hang screens on trusses, but very often we just pick them up directly from a few distributed hoists. In this scenario, we have no need for BW calculations since we don't expect BW to know the structural specifics of how the header bars and panels transfer load, we have separate data for that. But we need this for being able to export an accurate drawing of hoists picking up header bars, particularly as an elevation.

- Be able to hang said header bar (and LED below) on a truss. This we obviously do want the BW calculations to run for.

- (Lower Priority) - an option for 'show symbol' on the LED screen tool, to replace the simple block with the manufacturer's frame. Most LED panels have various features and connection points (particlarly like the dorsal connection point shown below) that are needed to plan wind bracing and other such things. For the sake of processing speed, we would turn the relevant class off for most of the time and have a 'simple' panel within the same symbol, much like truss.

I would appreciate any advice on how the above can be acheived, please, particular in a way that will calculate properly.

Thanks

Simon

All of this is perfecting articulated, and I wish it existed, so I could use it on most gigs.-

1

1

-

2 minutes ago, Kevin Allen said:

I don't think Braceworks supports ground supported systems?

There's a way to fake it with motors instead of towers. Also, in 2023 there's an added overall structure weight that I haven't tested yet (like PSF).

-

13 minutes ago, Kevin Allen said:

The center connection is insane and has NOTHING to do with real life.

What's also making me suspect this is that Insert Connection tool / functionality includes drops which are also (very logically) centered. They could be a dead hang or a motor, attach to pick or sling (also obviously centered)...

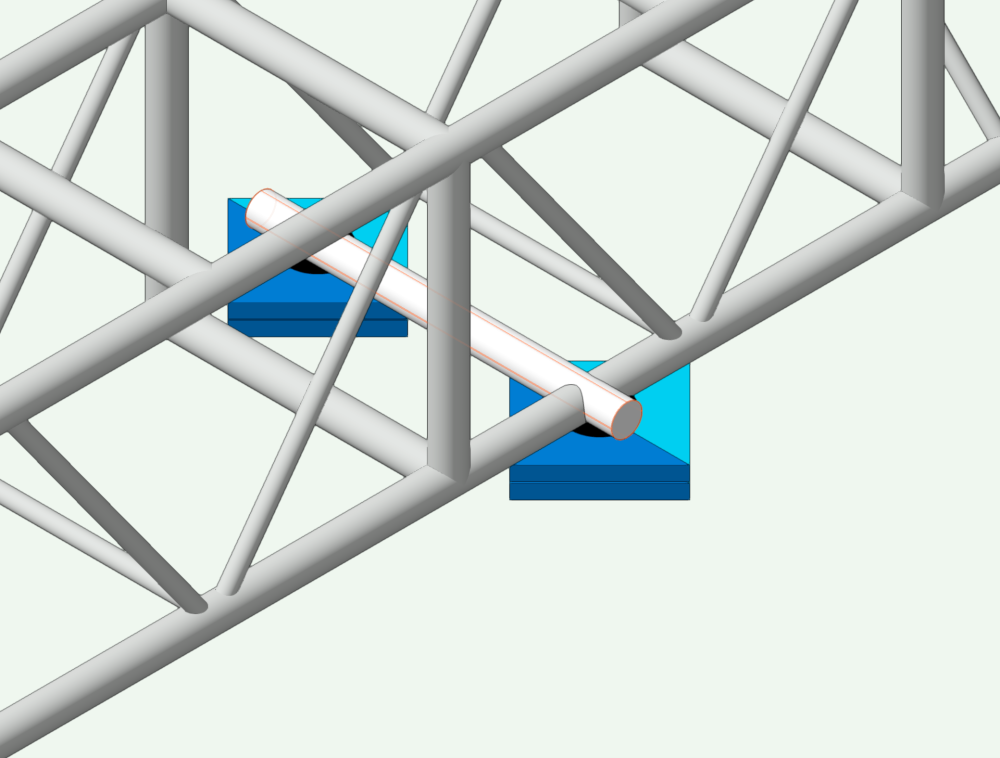

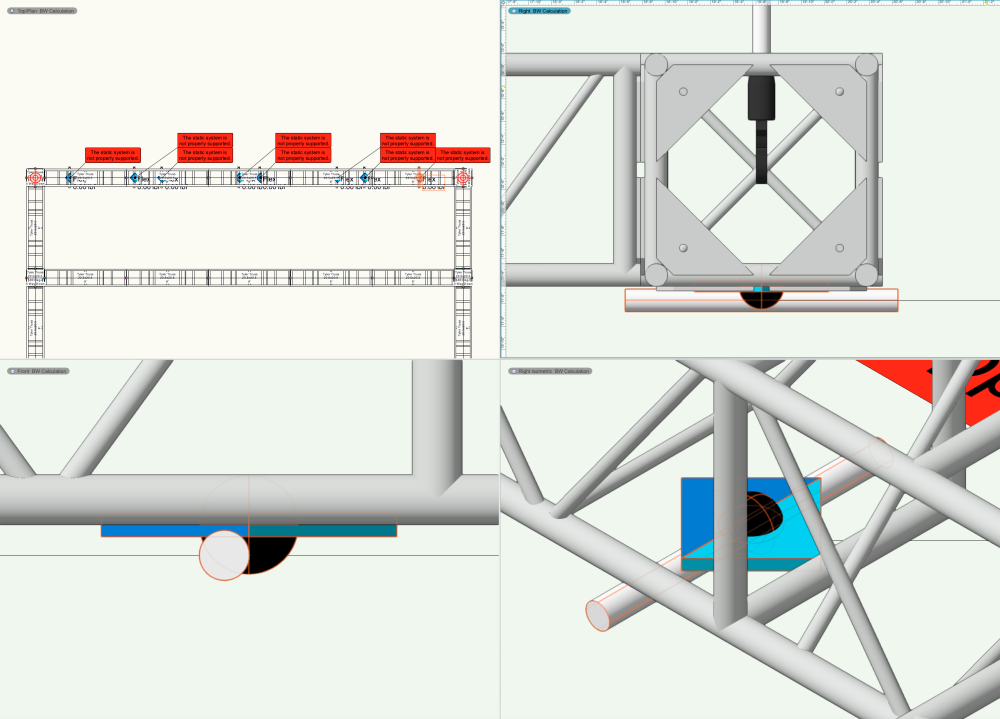

The only way I can force the pipe to attach to both chords is by juking the insertion point, which is totally fine because I'm using it to replace clamps attached to each chord but for some reason it won't attach to both chords on the perimeter truss (again, I wouldn't have to do this if Insert Connection could sister truss):

-

1

1

-

-

I'm the biggest defender of BW but I've also lost immeasurable time and energy fighting with it to accomplish the simplest systems.

If it's just hanging truss from motors, it's green lights all day.

However, as soon as I move to a ground supported installation, welcome to workaround city.

The main issue with this system is that the design team has sistered Unistrut to the truss it's hanging from. Hence the perpendicular pipe connection. I honestly feel like I'm missing something super obvious because it can't possibly be this bad.

-

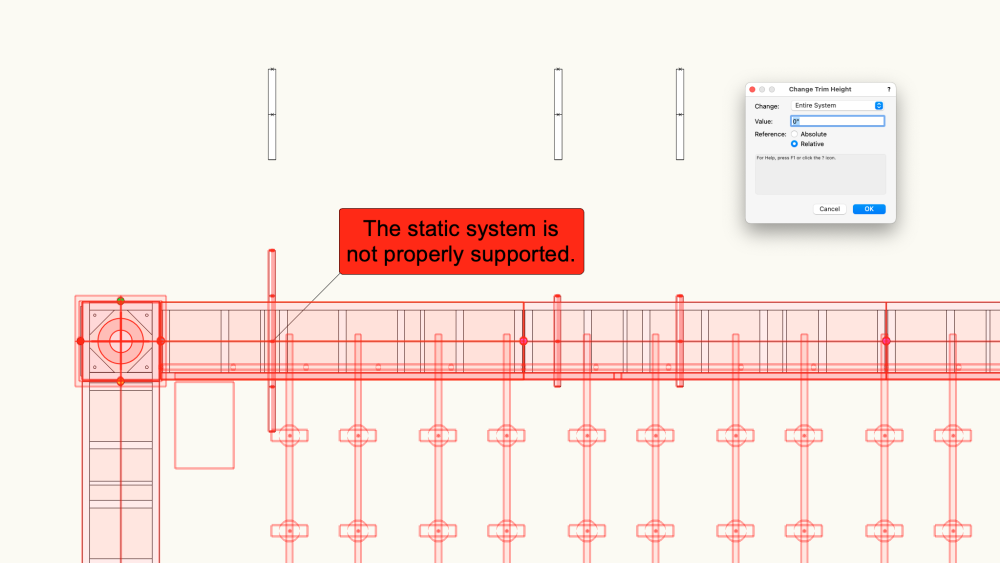

Nope, same thing happens with pipe.

For context, as soon as the first one fails, it stops the calc. If I delete that pipe, the red flag will move the next pipe.I hate to say it but at what point (pardon the pun) will I get reimbursed for the DAYS of beta testing Braceworks while my producer misses deadlines?

-

1

1

-

-

The 2' pipe is a truss object. Should I just use a regular pipe object? Is that a thing now in 2023? It's just a placeholder for clamps, so I could care less what the object/symbol is.

What appears to be happening is the connection is auto-connecting to nothing because truss objects are set to autoconnect at their centerline.

I was able to force most of the to connect to the chords when offsetting the insertion Z but that also had fail points.

What the heck is going on?

-

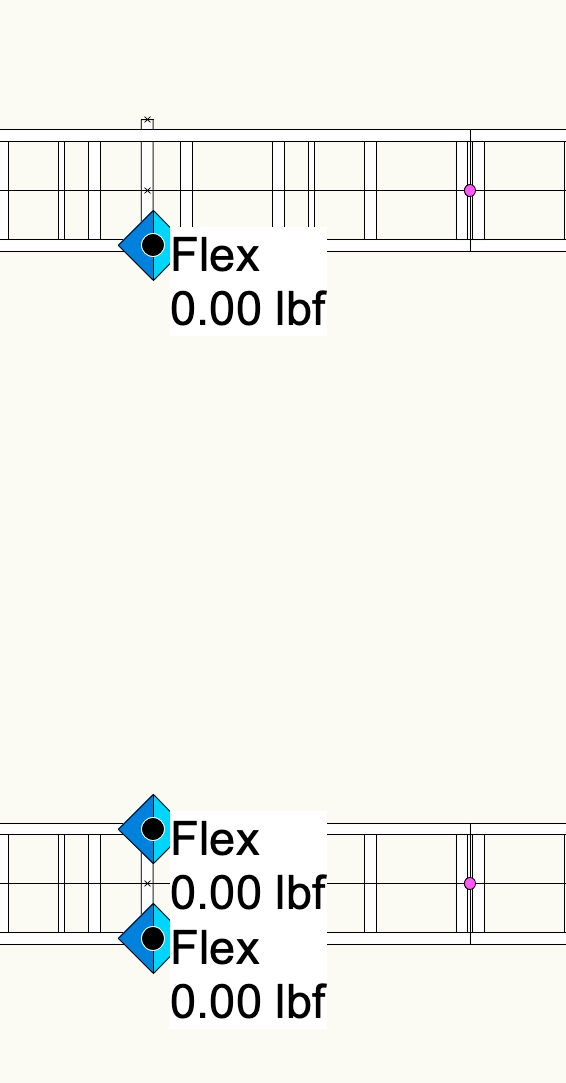

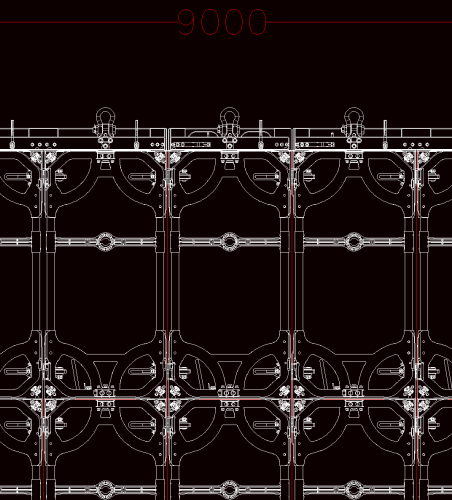

There are A LOT of them, and I'm wondering what is causing this issue (other than a bug) because that could be a clue to the errors I'm trying to fix.

Also, they reproduce quickly on their own.

-

Not sure what's causing this but I have to find and delete the duplicates:

-

45 minutes ago, Malovejr said:

Yeah,

The files I have been receiving have everything in the none class which drives me crazy as well.

I don't have Rhino and I'm not familiar with it. I tried downloading a trial version about a month ago to see if I could clean up the files in Rhino before importing them into Vectorworks, but unfortunately I just don't have time to sit with it. It feels like the show I'm on is more of a sprint then a marathon.

I signed a bunch of NDA's which prevent me from posting the .3DM files here.

Yeah, they have offered to File-Save Small, but it doesn't seem to help much. They also said they are reducing the Nurb count on the files they are sending me.

They have tried giving me OBJ's. The problem with OBJ's is that parts of the set come in giant chunks. I can't turn particular things on/off or highlight where we have LED's running throughout the set.

@Josh Loyis a good person to send files too. I just sent him a few STEP files with the same issues. -

The “dumb” way of managing this is to export multiple files for each dept. Just make sure to include alignment guides for XYZ (for when you reassemble everything in VW).

-

1 minute ago, Kevin Allen said:

maybe there are several VEs here? a) better import and translation. b) referencing.

Not sure about referencing but there a bunch of VE's for VW to not flatten layers when importing exporting. They never get any love.

-

1

1

-

-

1 hour ago, Malovejr said:

Hello,

I work in the film industry and I am currently receiving Rhino (.3dm) files from our art dept. The files are somewhat small as Rhino files, but become massive once I import them into Vectorworks. Has anyone found an easy solution to working with Rhino files?

I'm constantly wasting tons of time every time there is a new set. It can take as long as 30 minutes to import the files and then moving around is super clunky. I'm constantly going through each set to class everything, and then deleting as much as I can get away with (nuts, bolts, etc...). The current set I am working with is a 1.5G Vectorworks file. Moving around is very difficult and I'm going crazy trying to figure out the best way to work with art dept.

I have heard of art dept drafting in Rhino for other shows, however this has been my first time experiencing it for myself.

Any help / suggestions working with large Rhino files would be appreciated?

Thank you,

Mike

My Computer Specs:

-Apple MacBook Pro

-M1 Max

-10 cores (8 performance and 2 efficiency)

-64GB RamIf you have a Rhino license, there's an option to File > Save Small.

Then again, if you have a Rhino license, you could export a bunch of other file formats that would also preserve layers.

-

56 minutes ago, Malovejr said:

Additionally, the .3DM file I received was around 250,000 objects. Currently its around 150,000, but that has only been after hours of me going through and deleting as much as I can.

Also VW flattens all objects to one layer on the none class when importing and exporting 3DM which is the bane of my existence.

-

1

1

-

-

2 minutes ago, Kevin Allen said:

Is it possible to reference this type of file?

Great question.

-

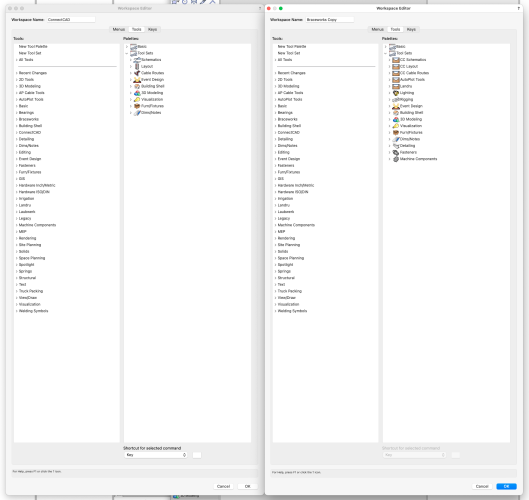

Horz, towers, CB's...

I can't find a cut sheet for the CB's, so I'm still digging for that weight.

Toolset picture files.

in General Discussion

Posted

Retina icons attached: