-

Posts

1,193 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Sam Jones

-

-

An understandable need, but currently, there is no way to do that. I have heard from a bunch of people about different info they would like to pass between fixtures and cables, and additionally, functionality that will do appropriate deletions. Hopefully this will be added in future versions.

Thinking about it. I can probably create a modified "Assign Multicable Circuits" command that does what you wish. Do you just want the Unit Number or would you want the position name and unit number.

For example: FOH - #9.

Can't give you an ETA for this, but working on it will be a nice occasional break from a currently onerous project.

-

How is it that you wish to do this? The "Assign Multicable Circuits..." is the command that extracts the information. The information it extracts is put into the Circuit fields of the selected Multicable. If you want to change what is collected and put into the Circuit fields, you need to use the "Circuit Assign Preference..." command. That command will let you select a different Lighting Device parameter to place in the Circuit fields of the selected Multicable. If you want to do something different, what would that be?

-

You have combined and mixed together fields from different Object Info palettes (OIPs). A "Hanging Position" does not have a "Trim Height" parameter only a "Hoist" object has a trim parameter. The Z Height on a Hoist is the Z height of the low hook. The "Load Trim" on a Hoist is the lowest point of the load hanging from the low hook. So... If a 12" x 12" truss is hanging from a Hoist the "Load Trim" parameter will be 12" below both the "Low Hook Height" and Z parameters of the Hoist. Of course there will be fixtures hanging from the truss, but it is the truss that is considered hanging from the Hoist. You can continue with your work flow, but if you include Hoists the Low Trim parameter of the Hoist should be set to equal the Z height of the Hanging position.

-

I am under the impression that VW stores mass internally as Kilograms, and that it uses the mass unit settings to determine how to display mass. It is a shame that those mass settings are not available to VS, since there are many simple arithmetic scripts and worksheets that could be constructed if they were.

-

Is there a way one can find out what structural (weight) units a user has picked for a drawing? I imagine that it is a GetPref() call, but I can't find it. Hopefully it exists.

Additionally, does anyone know what metric units VW uses to store weight?

TIA,

Sam

-

A vectorscript could certainly do this, but... Since they're all selected, why not renumber them all starting at 11? Also, using a Hanging Position or a Lighting Pipe you can have it auto number.

-

Have you managed to get ODBC to work with any 2 programs? Perhaps Miguel Barrera is a place to start, but I think ODBC is just too hard, and it isn't all VW's fault.

I'm sure someone at VW has gotten ODBC to work, but the LightWright / Vectorworks connection is not an example. John McKernon, the author of Lightweight and VW collaborated to hard code a connection that uses XML files to pass information; no ODBC involved at all.

-

Yes it was as was the example that twk pointed me to. However, I was not able to determine how to fit which indices in my process would be fit into the ProgressDlgStart() and ProgressDlgYield(). I'm sure continued experimentation would have yielded an answer, but during the experimentation that I did, I found a solution that did not involve a progress bar, so I moved on.

Again many thanks.

-

Where can I find Dialog Builder for VW2018?

-

The window plug-in is part of Vectorworks and the orange in an apples to oranges comparison. The trick is constructing a user interface that will allow one to construct a custom connection with any other program that supports making such a connection. This problem is unique and not appropriate to compare with plug-in object programming, such as the window object.

ODBC has never been easy. In fact getting ODBC to work is a hell of lot harder than scripting. This has been the case with every program I have tried to hook up to Filemaker using ODBC. The production company PRG Hamburg got ODBC to work but only after scouring Europe. They found one guy, in Switzerland, who they paid to construct the connection. When you don't have control of both sides of the action, it's going to be exceptionally tough to create the user interface.

All that being said, if VW could solve the problem of creating an easy user interface for constructing a live connection with an outside database, it would be @#$%& fabulous.

Hippocode, ok, don't advertise. Send me some examples privately, they will reshape the terrain I'm working in.

Sam

sjones@autoplotvw.com

-

5 hours ago, Don Seidel said:

Vectorscript? Why? It's (year) 2017...VW is supposed to "connect" to an external DB without fuss. Particularly on the Mac OS and particularly with FM Pro, it should be a snap. One should NOT have to be a VS or DB Geek to set it up and make it work, and yet the instructions are not clear & simple. I've looked but never seen a simple VW file example w/ associated DB.

OK, that would be nice. Where have you seen this. The "this" being an easy way for an end user to set up a custom configured connection between two separately created and marketed programs to seemlessly share information. I'm sure this is the future of personal computing, but I haven't seen it or heard of it. I would love to check out any examples you can point me to.

Currently, VW seems to provide the most easily accessible tools for creating such a connection between CAD data and database data. Easily? No. More easily than other CAD programs? I think so, but my familiarity is not that great. Show me.

-

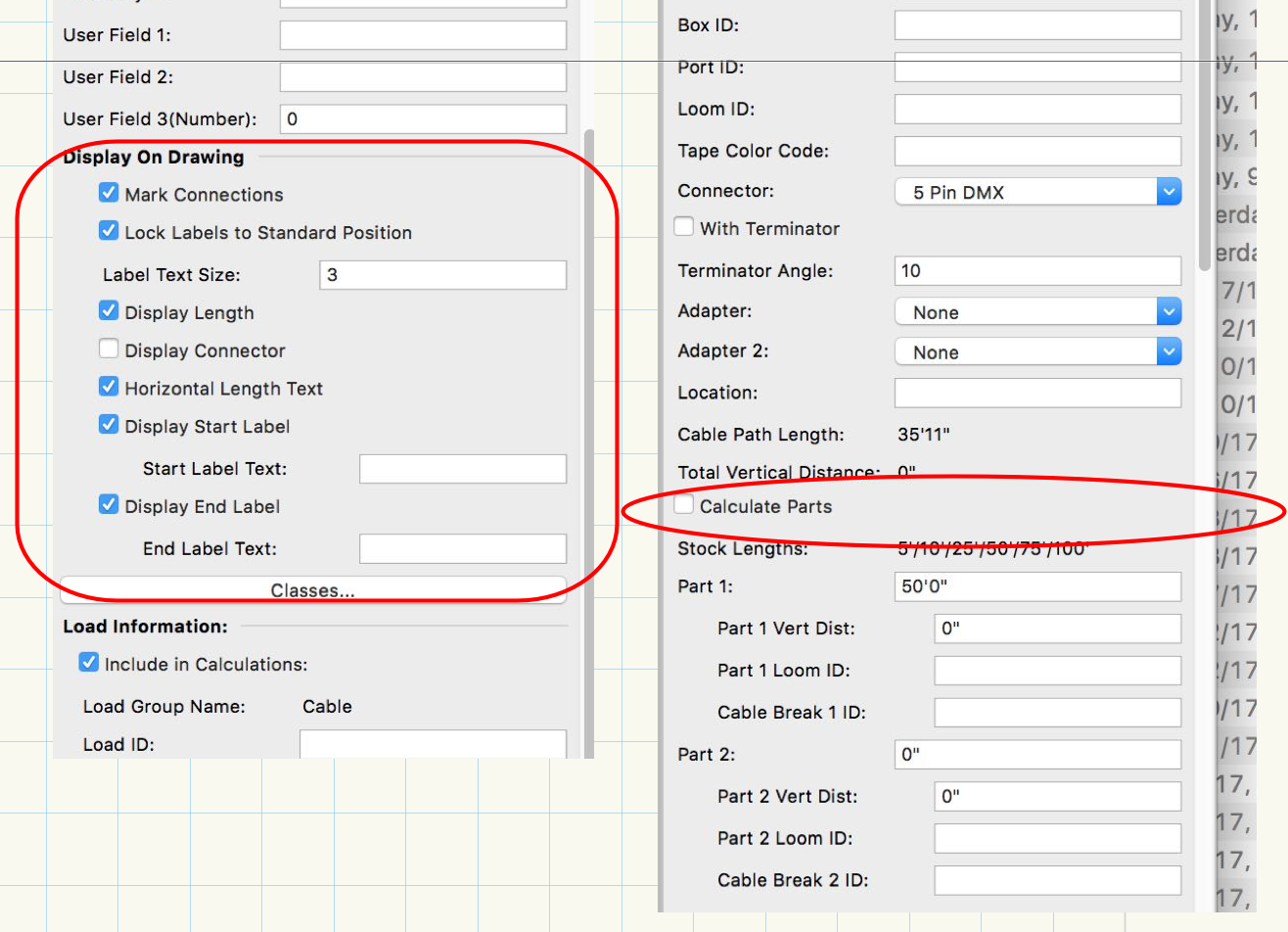

Play with the check boxes under the "Display On Drawing" divider. You will not have anywhere near the control you desire, but you will have much more than you seem to realize.

Also, unchecking the "Calculate Parts" button will allow you more freedom in assigning part lengths.

-

1 hour ago, RedBassett said:

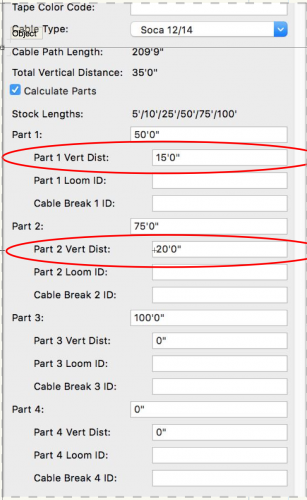

...since I am drawing out-of-scale with the rest of the plot (because the cable tool doesn't take 3D model shape into account, so a "50ft" run may actually be 50ft horizontal and a 25ft drop at the end that isn't show in my plot) the amounts I get are completely wrong.

I can't help you with the problem of displaying "extra" or formatting the text, but...

You should be able to type in the value of the vertical runs into the vertical distance parameter of any part so that your amounts are correct.

-

Thank you, Obiwan!

-

Can anyone point me to instruction, examples of how to use the ProgressDlg calls? The Function Reference is unhelpful.

Sam

-

9 minutes ago, MeTheMachine said:

On the flip side, the same workflow ( i know this would be a separate script) that could handle the import side and update the instruments.

The import command in AutoPlot should work, but it will require the creation of tab delimited file to read; Filemaker should be able to handle that. The info has to be in the same order that it was exported, and the first line should contain field names which will be ignored. I haven't used the commands in quite some time since I work with Lightweight, but I just tried a very simple test file, and it seems to work as described.

In terms of using keystrokes to activate commands, this can be done with any AutoPlot commands using the Workspace editor.

HTH.

-

OK. In your original post, you said you wanted to export and import instrument data. Which instrument data? Here are some questions that need to be answered. (BTW I have written routines to do just this)

1. Are you using Spotlight?

2. If so, do you want to export information contained in the Object Info Palette (OIP) of the Lighting Devices instances you have placed?

3. If you are using Spotlight but do not want to export information from the OIP, what information do you want to export/import?

4. If you are not using Spotlight, what information do you want to export/import? If you can identify the info, it can be exported/imported?

It would seem from your examination of the OIP that you are using Spotlight and want to deal with the OIP data of the Lighting Devices. If this is true, forget about the data tab. What you want is the data contained in what is called the parametric record, called "Lighting Device"

Penultimately, however you identify the information you want to export/import, the actual work will be done by exporting and importing text files, either tab/comma delimited files or XML files. Forget about calls to Spotlight menu commands. One work around, might be creating a custom report and then using the export worksheet command to create a tab delimited file.

Lastly, Pat is correct I have written commands that export/import Lighting Device information. They were designed to work with Lightwright 4, before the advent of data exchange, but they just write and read text files. If you end up looking into AutoPlot, feel free to ask me questions.

If you want to learn programming just for this task, you have something of a learning curve; as to whether it is steep or long or both is to be determined. If you are new to programming, you will need to learn about "handles", "variable scope", flow of control, variable and static variable procedure parameters, and a host of other things. As a ray of light here, I can tell you that Andy Dunning taught himself to program after teaming up with master Vectorscripter, Gerard Jonker to write video screen tool, he continued to write a bunch of cool stuff, much of which has been incorporated in VW.

-

In vectroscript, you can create tab delimited text files with any of the information you describe.

Open(filename);

PutFile(prompt, defaultfilename, filename)

Write

Writeln

I'm sure there are Python calls to those commands

-

You will need to make symbol(s) and attach a record to them. The record will be made up of fields that hold the information you want to display. In each symbol, you will need to place text objects located where you want your information to display. Each text object can be connected to a field in the record that is attached to the symbol, so that it displays the value in the record field of the placed symbol instance. You will need to use the "Link Text to Record..." command under the Modify menu to do this. You can get away with just one symbol for everything if you have a record field that identifies the object and is displayed in the symbol.

HTH.

Sam

-

1

1

-

-

Structural units are weight units. You can now use weight units instead of text strings and it makes math in worksheets easier to set up. I'm sure it was required for Braceworks.

-

I realized that Easy Cargo does not allow you to make schematics of the load, e.g. moving items on top of other items to the side of the plane view. one could print multiple views, but those are difficult to hand off compared with one schematic. Back to my truck packing commands. Maybe I'll use Easy Cargo to suggest packing arrangements, but double entry will discourage that.

-

1

1

-

-

I have found that I can enter values in the OIP while multiple units are selected and have what I type applied to all selected Lighting Devices. You might try the same thing in any applicable dialog.

-

I want a command, tool, or PIO to be able to query what structural units are selected for a document, and l want to be able to set a documents structural units.

-

Using VS, is there any access to a documents structural units. Can we find out what they are? Can we set them? If so, how ?

How does the Lighting device interact with the structural units? Can I set values in the "Weight" field? Can I set values in the "Total Weight" field. How do those fields interact?

Linking fields between objects

in Entertainment

Posted

How about putting the Unit Number in a User Field?