AStein

Member-

Posts

60 -

Joined

-

Last visited

Reputation

10 GoodPersonal Information

-

Location

United States

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Truss build out of NURBS. Runs poorly. How to convert.

AStein replied to AStein's topic in Entertainment

Thanks Justin. I actually didn't have the easiest time getting this from the fellas at XSF. The files are missing on their site and I had to reach out to a couple folks to even get this. But, yeah, I think I have clif on an email somewhere. I can reach out again. -

Hey guys I was sent this DWG for stackable truss I'm putting out and it's NURBS curves (attached). Completely nukes whatever drawing I put it in by making it run unacceptably slow. I'd love to understand how to simply convert this thing into shapes that Vectorworks likes. I'd also like to convert this into an actual truss symbol, if anyone has a link to some decent documentation on that. Thanks! X-SST-30x36-375FE-120 (1).dwg SST Example.vwx

-

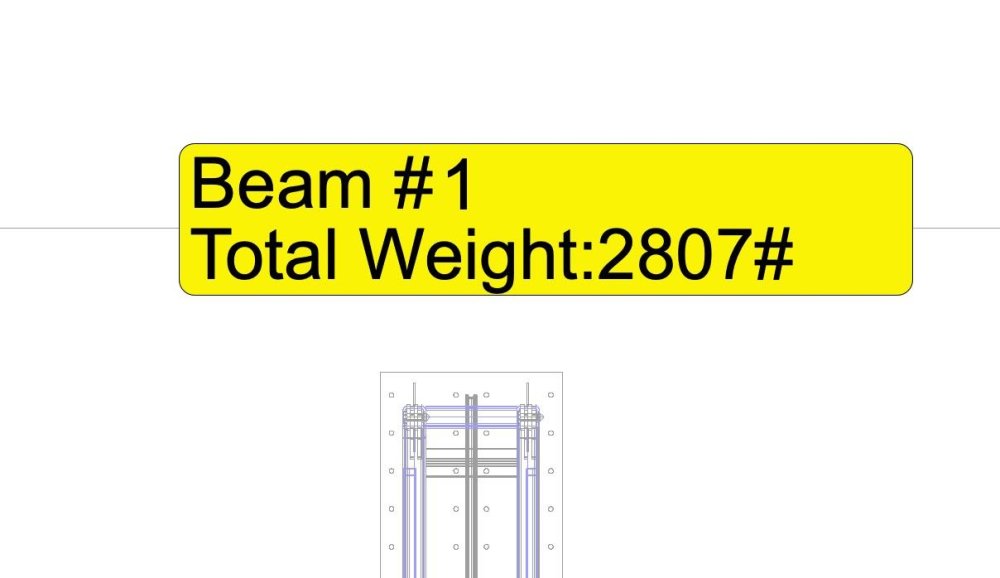

Alright, thank you. If I can't think of something clever I'll go ahead and make 20 different ID tags, one for each beam and keep them in my boneyard file.

-

@Pat Stanford Worked like a charm Pat thank you. I ended up doing a ROUNDUP function instead of TXT to keep it as a number, but I don't know if that'll matter or not at some point. My question now is if there's a way for me to pass the user entered tag field into the formula WS coordinates? So for beam 1, the worksheet cell I want to grab is B4 and add 3 to it, which will point the tag to the right cell. #WS_CONCAT('Beam Weight Calculator':B4)#'#' That's my current function #WS_CONCAT('Beam Weight Calculator':B"Beam # + 3")#'#' And this is the type of thing I'd like to make work. When I put single or double quotes around the characters in the cell coordinates if breaks the function so I'm not sure if there's a function to pass text in or something?

-

Hello! I have a big, complicated worksheet to calculate individual beam loads for me and I'd like to represent this nicely on my drawing. Is there a way to visually and dynamically reference an individual cell from a data tag? My backup plan is to create a new worksheet for each beam because I can reference worksheets from other worksheets, but this is very cumbersome. Thoughts? Thanks ahead of time!

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@Sam Jones You know Sam, you've pitched your software for enough of my problems that I'm really curious. I have two more avenues left to try before I buy another VWX tool, but I wanted to say that I admire sales acumen. -

@klinzey Copy... I think my workaround will be to have a special layer where I import everything I want to calculate, then dump the hoists into to rig layer after they calculate. They seem to retain their numbers if I do that. @Stefan B. You know, I've really run into headaches with that. if it were just my office and/or I was working with the same people a lot more I might cement that workflow, but using a dropbox folder that I set up for them is almost too much of an ask half the time... I actually run into this sort of VWX wrestling match a lot. I'm on a project right now where I'm integrating and was excited because other departments seemed on-board. LX said he used VWX symbols and truss so I'd finally get to use Braceworks as intended rather than replacing everything with BRX-friendly truss, manually adding up the lights and doing a UDL... Then i import his layer and it's all customized symbols from enough versions ago that nothing works or connects... It's kind of my larger frustratioin with Vectorworks... In theory, these are some awesome and easy tools, but they're too engineered. Like how we still can't hang a torm from a single hoist?!?! Literally every show I do...

-

Connecting a single hoist to a vertical truss

AStein replied to Mathijs van Ommen's topic in Braceworks

Is this on a list to ever get fixed? I've got torms in almost every show I do and I can't throw off my truss and hoist counts wrestling with workarounds. -

Hey guys. Is there a way to get hoists, truss and instruments to connect and communicate with each other on separate layres? Basically, the workflow is this: I create a dropbox folder where each department gets a sub folder and a master file. Then we all reference each other with reference layres. I would love to keep all the hoists on a hoist layer rather than having to import other departments layres then work inside their layres with my rigging stuff, and then having everything break when they make a small change that I then have to re-import. Thank you.

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@msharonThe Life-Size data tag is is a really interesting idea, thank you. The pitfall here is that I have a show coming up with a bit over 300 hoists so I'd need a way to automate the layout and pagination. Does vectorworks have anything like that? -

New File attached. One step closer. If I drop a "power in" component on the hoist symbol definition then the distro recognizes it and shoots a cable over there and/or the cable tool acts like it should. But if I move the hoist, the cable node wont follow like it does with a lighting device. I have a lighting device on this file that uses my custom "hoist cable" to make sure it wasn't my distro or cable, but it seems to like them just fine, so I think we're down to troubleshooting the hoist now. "Consumer" on the hoist doesn't seem to work, it likes the "power in" component. I also tried converting the hoist symbol to a lighting device, but it didn't let me. Cable WIP.vwx

-

@jcogdellAttempted file attached. So, I went into the cable XML file and made some hoist cable. Changed the symbols on the distro to "consumer" Everything seems to match. I can get the "end" to lock onto the hoist, but it still doesn't like the distro. Thoughts? Cable WIP.vwx

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

Interesting. -

@jcogdellCopy, thanks Jesse. I'll give that a try tomorrow morning.

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@Sam JonesYeah, one of my guys got really interested in trying to find a 2" wide soft tape and putting labels or tabs on it. I think truss tape alone for layout would be problematic because of how fragile it is, but something like that would look slick... Maybe a roll of vinyl? I don't know, I don't really have an issue with layouts done the "old fashioned way". The stickers are more to serve one-offs/festivals when there's just too much data to scribble with chalk effectively... Also, it tooks great when the bullseye of each sticker is my client's event or logo 😉 @Mike RockOhh! That's really clever, looping through to look for what's close and 2nd closest. I should really play around with LLMs eh? But that is a rough version of what I'm looking for. I agree that rigging is super-segmented and informal. I think one of the major issues in my market is that it's nearly impossible to run a vendor-based rigging company since other vendors just decided to buy their own truss and hoists and generally undercut what it's worth to rent in order to better sell their higher-margin instruments. Then, they can never get the best riggers to sign on because the mindset and pay expectations between departments is so vast... Anyway, that's why we're all over-opinionated, entrepreneurs who each have our own dogma based on how we came up in the industry... It's not great. But that's also why we're often frustrated with how closed-off Vectorworks can feel.