MaleXLR

Member-

Posts

80 -

Joined

-

Last visited

Reputation

5 NeutralPersonal Information

-

Occupation

Draughtsman/Sound Engineer

-

Hobbies

Family, Home, Sound, Architecture, Karate, Rowing.

-

Location

New Zealand

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Vectorworks 2018 Crashes Immediately After Opening

MaleXLR replied to Jeffrey's question in Troubleshooting

@JuanP As @DonnaS suggested, this does appear deliberate on the part of Vectorworks to force users to upgrade! Do you think that as a show of good faith, Vectorworks might address this issue and fix it? I haven't logged incoming and outgoing port activity when Vectorworks 2018 closes down, but assume that the problem is part and parcel of the monitoring that Vectorworks and their distributors are able to do, rather than the activation process. I know that as part of this monitoring, distributors have a log and are able to see where a license is being used, what the device name is and for how long the user has been active... I have always thought that this was a little over the top and wondered how many countries would have privacy laws that would disallow this behaviour!?! -

Vectorworks 2018 Crashes Immediately After Opening

MaleXLR replied to Jeffrey's question in Troubleshooting

Okay... after dwelling on it overnight and while working (on a different computer) today... Playing around with opening and closing ports achieved nothing but hours wasted. Ditto adding a Program rule to allow Vectorworks 2018. HOWEVER, I created a Windows Firewall outbound rule that blocks Vectorworks! Sort of the opposite of what JuanP suggested. The problem may be that occasionally Vectorworks goes off to check its Activation and with this rule in place, it won't be able to. Perhaps Disable Rule > Activate Vectorworks > Enable Rule. But - Vectorworks 2018 lives on Windows 11!!! -

Vectorworks 2018 Crashes Immediately After Opening

MaleXLR replied to Jeffrey's question in Troubleshooting

Old post, I know, but did anyone try JuanP's Firewall suggestion and did it help? 6 copies of VW 2018 working fine on Windows 11. 2 copies on new i9 computers and closing down immediately while on-line. It appears as though both copies activated correctly, but cannot be used... -

Slightly above my pay grade sorry, but I think if you create a symbol from your door there should be an option to "Insert in Walls" and I think that will do what you want. As far as hardware, I would probably create symbols from those and make sure that the insert point makes sense ie: maybe hinge insert located at the bottom corner of the door on the hinged side and handles insert located at the bottom corner of the non-hinged side, but I am sure someone will have a better way!

-

Possibly/probably very obvious, but how do you export from Vectorworks to 3MF please?

-

Sorry, you probably have solution already. Any chance that on the Object Info Palette it was showing up as Fillet or Chamfer? I had much frustration with models that I had painstakingly filleted and then wanted to change the solid modelling. The only way to do it was go through and ungroup multiple times to get back to before the last fillet command...

-

I don't know whether mine has been the same issue, but often the object is not visible, although identified in the Object Info palette. Once dragged in, I have just been cutting, clicking a point on screen and then pasting, then wherever it had wandered off to it was back where I could see it! Other than that, just the obvious, ie: are classes set to Active Only and are there perhaps strange classes or layers embedded in the imported [or not imported] object?

-

I am a novice with 3D printing but have already wasted much time and printed many useful (and even more useless) things! Question: Can anyone tell me whether there is a resolution difference between exporting Vectorworks to STL as solids rather than converting to a mesh first? I am currently printing a Sennheiser microphone housing (c1960) which has many curves and am less than happy with the results so far. When sending to the slicer I tried converting the model to a mesh, but on screen the curves seemed to have lost the smoothness that they had as a VW model so I created the STL directly from the model, ie: skipping the "Convert to Mesh" stage... There is a "Quality" option when exporting to STL, but presumably "Convert to Mesh" defaults to the best resolution it can get!?!

-

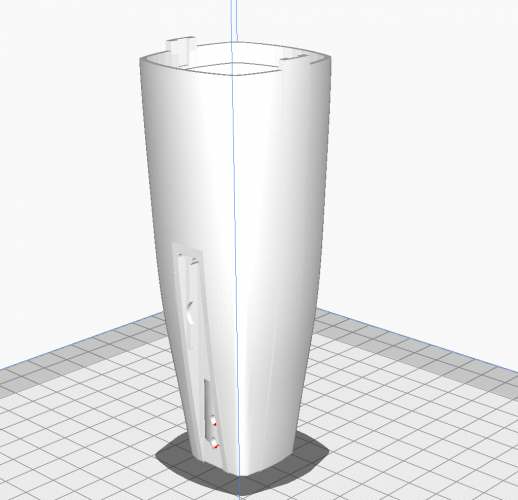

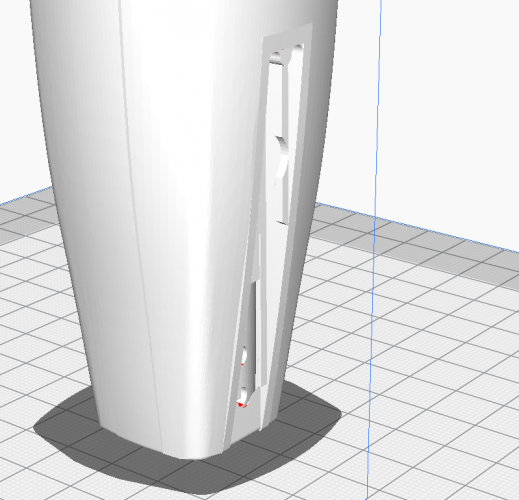

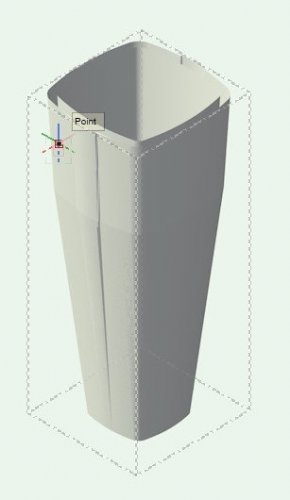

Nearly there, having tried various methods. Most of it uses the loft tool. I do have a problem with the area around where the mic clip goes, as it protrudes beyond the housing. I did prepare the perfect Sweep to tidy it up, but that was the point at which it wouldn't do any more solid subtractions! Bugger!

-

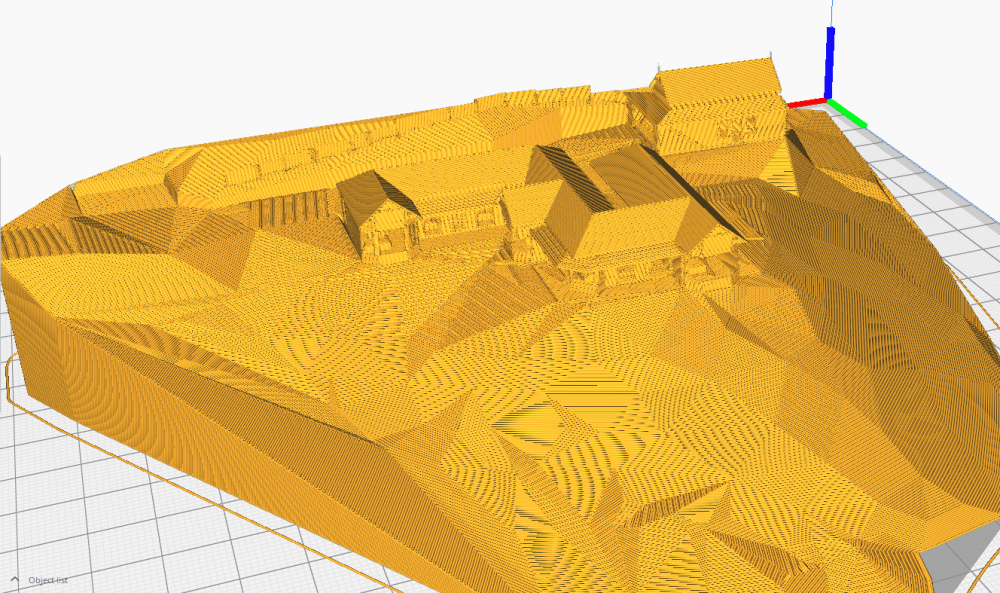

I did try just the site model on its own, but still couldn't get it looking smooth. I didn't want just the contour lines as per your print, but the smoothing just seems to be cosmetic for rendering and traditional rather than 3D printing. Thanks, I'm happy to send the file. Will just have to remember to dig it out while I'm in the office.

-

Hi Mark, Sorry this is an old thread, but... I have a job where it would be handy to be able to show their renovation in-situ. I am almost there with Cura, but would appreciate your input please. Incidentally, I was able to scale within Cura rather than having to import the STL back into VW. 1. Is it possible to get the smoothed version from VW, rather than the faceted version that is created with he STL? 2. Those dreaded roof overhangs! I have tried converting the site to a mesh, but still end up with an angular site. Not the end of the world, but it would be better smoothed out without having to redo the site model: I haven't done a building print yet, but have spent much time worrying about soffits, eaves, overhangs, etc. For a larger scale model I imagine that printing the roof separate from the walls would be the best idea!?! I did wonder about printing upside down, but that's a lot of support structure to remove! In this instance, I'd rather just be down and dirty and printing upside down would add extra time and material, not just for the roof and site, but also the finials! Any help would be greatly appreciated...

-

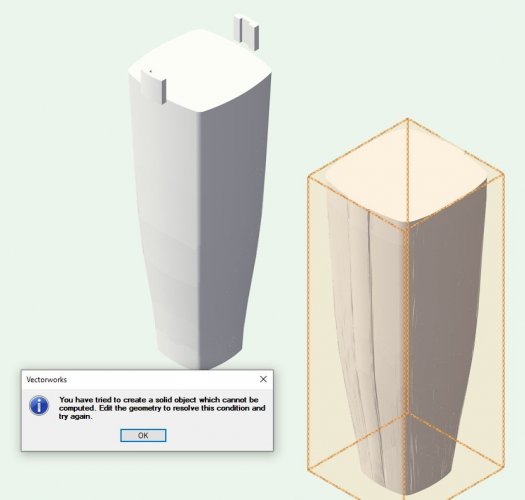

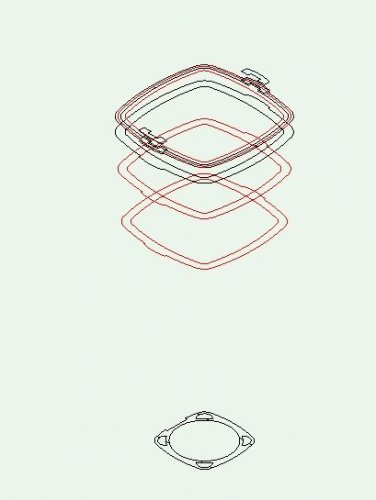

Unfortunately, this often happens when I try to subtract one mesh from another. If there is a secret I would love to know it! This is the easy part of the subtraction... I have more complex subtractions to do. Any ideas please?

-

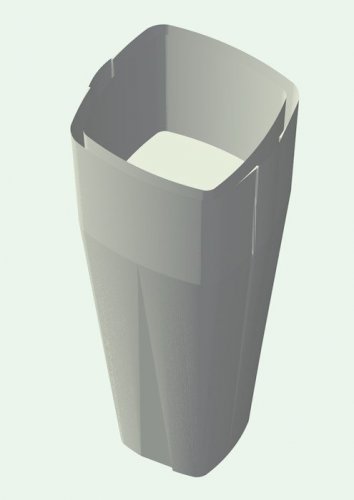

Thanks Pat, that's just the ticket... Outer shell created with Loft Surface and when I have time, multiple solid subtractions to finish it off. It's a Sennheiser MD421-N microphone - works particularly beautifully on snare drum even though it is a dynamic mic! [Drummers tend to hit expensive condenser mics anyway]

-

I have an (almost vintage) 1960s microphone, but its housing broke with a previous owner and it currently has a modern (gunmetal coloured) housing rather than its original white. Over the years I have tried, but failed to get a replacement. Could someone lend a hand as to the best method to model it please? I am hoping to create an STL file and chuck it through a 3D printer. It may not be perfect, but it will have more than a hint of originality. So far I have started a sequence of cross sections at 20mm intervals (mainly) and the images are a trial with Terrain and AEC. That might work, but so far gives me distinct "skins" that should be solid inbetween! I thought that Loft Surface may be the tool - but possibly not!?! Is there an easy method or do I have to do it long handed with extrudes and meshes? Many thanks.

-

Is it only me that can see the injustice (verging on corruption) of this and is it only with the advent of "IT" that businesses feel they can get away with this? We all know that the Title Block Tool is just one of the many components that doesn't do entirely what it should do! VECTORWORKS 2018 (as well as previous versions) IS DEFECTIVE... If you or I bought a microwave oven and found that it didn't perform or meet its written specifications, it would be within our rights to return it for a full and unequivocal refund.