-

Posts

1,330 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Stephan Moenninghoff

-

-

Sorry if we missed something, @Ride. Whom did you approach? As @Woodychips said: it's out.

-

You can adjust the door width by increasing the gap, then attach a free custom part. Or you could draw the opening triangles and put them in the same class. many options...

-

Hi Dave,

We have a FAQ article on managing the material database. https://en.extragroup.de/faq/ search for "material". Let me know if questions remain. Thanks!

-

Hi Dave,

You mean horizontal bifolds? We do not currently support those from within the cabinet object. We have recently added support for vertical bifolds. You can still make them quite easily by adjusting the door width and adding an extra panel. We will add horizontal bifolds to the cabinet as well. No timeline yet.

-

Hi Martina,

can you check the origins of this file please? Vectorworks won't open it, as it tells me the file was once edited with an illegal version. Not necessarily your bad, but you may want to check licensing. I cannot get this to open at my end.

Here's more info: https://piracy.vectorworks.net/IllegalFile.php

-

Yes that should work. Please always attach a document, not just a screenshot. I'll have a look. Thanks!

-

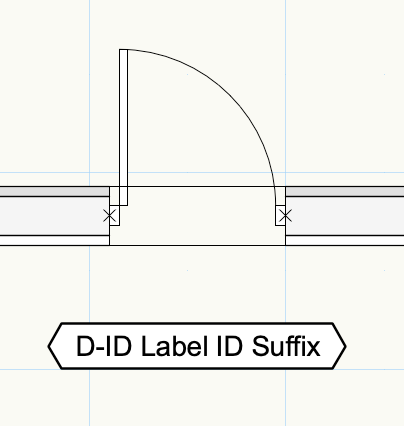

Here is a Datatag which uses the tagged geometry's object data to draw a hexagonal label around the text. I made this to get the label to adjust to the text without distortion. You might be able to adapt this.

-

1

1

-

-

Were you working on a Marionette?

-

Hi Ed,

That shape is not supported (yet). You will need to use individual custom parts to create something like this.

-

No, we don't allow it. We will need to make some changes to this as users have been quite unhappy about it but this change will have a lot of side effects and is a big project.

-

1

1

-

-

4 hours ago, Ride said:

Not to hijack a thread, but what would it take to get InteriorCAD to export to Biesseworks?

You need Vectorwop, our CNC interface. It outputs CIX, directly to BiesseWorks.

-

5 hours ago, Robson said:

Hi Nicolas,

l am new to Interiorcad and trying to find info how to build cabinets and cut their components on our BIESSE CNC.

Can you help ?

ROBERT

Are you running BiesseWorks?

-

- Popular Post

- Popular Post

11 hours ago, MarcelP102 said:Space tool - Pick Up atributes and Apply use the same icon. Suggestion to use a bucket icon for 'Apply Attributes'

@MarcelP102 someone else has caught this one and I have since updated the eyedropper. I think it will be in one of the upcoming SPs. FYI: Cannot use the bucket because it is already being used for the boundary mode of the same tool!

Great thread. Always good someone is keeping an eye out for these things!

-

6

6

-

Hi @jasvars do you have the full version of interiorcad with Vectorwop? Have you had your initial setup? Please get in touch any time here: https://en.extragroup.de/submit-ticket/ and I'll have a look!

Thanks!

-

1

1

-

-

6 minutes ago, napwszzm said:

The problem might coming from the sample screw which only has a drilling instead of two.

I just checked and the sample screw appears to have two drillings. I have dragged them away from the centre to show them. Maybe you deleted one of the drillings previously?

-

1

1

-

-

23 hours ago, napwszzm said:

The only thing I concern is the drilling locations are not in the right place. When I changed the dimension of the drawer, the drillings, drawer positions are not changed parametrically, which showed in the early post.

Ok, I don't mind having a look at your library files but you need to upload them please:

On 8/5/2021 at 9:07 AM, Stephan Moenninghoff said:I need those files from your user folder under /Libraries/Defaults/Custom Part/.

Thanks!

-

Just a quick update on the situation: we are aware of the insertion bug with messed-up drillings and are working on a fix.

@napwszzm I cannot tell from looking at the document what is going on, I need your custom drawer library for that. I assume you wnet through interiorcad -> fittings -> Edit / Adapt Fittings Library and then chose Drawer Boxes, Drawer Profiles etc.? I need those files from your user folder under /Libraries/Defaults/Custom Part/.

One of the most common mistakes users make is to mess up the groups in the custom fittings, or they delete record formats. Record formats that are attached to groups will also be deleted if that group is ungrouped. We provide a sample geometry with each library document that can be used as a guide how to set up your custom fittings. It is advisable to use this sample geometry as a starting point.

-

Hi @Shawn please buy here: https://en.extragroup.de/buy/

Runs best on Vectorworks Architect but can be used with Fundamentals as well.

Let me know if you have any further questions!

-

12 hours ago, Habitat43 said:

Wanted to share one of my latest projects using InteriorCAD cabinets

Thanks for sharing. Nice project!

-

6 hours ago, Ride said:

Customizing things after with the suite of InteriorCAD tools is less intuitive.

@Ride I would like to make sure it does not stay that way. If you have particular cases where you think interiorcad could be improved, please let us know. You can either post something here (PLEASE always include a comprehensible file) or on https://en.extragroup.de/submit-ticket/. Happy to take a look.

THANKS!

-

2

2

-

-

5 hours ago, TimoG said:

is there any way to define new names for this? so that "side left-1" would i.e. always be named "SL1"?

Greetings and thank you

Timo

Not currently.

-

4 hours ago, jgmrussell said:

Now in 21 I'm getting Custom Part in the description box. Is there a setting or way to have part names assigned properly?

If it's a cabinet object, parts are named automatically. Like you said: side, stretcher etc.

If it's a custom part, you can assign a custom name via the "construction" button in the OIP. (We had a bug where any new name did not take properly. Can you download and install this version please:

http://upload.extragroup.de/IterationBuilds/Bockschus2021/installer/zip/interiorcad2021-F3-E-Win.zip)

Let me know how you get on!

-

16 hours ago, eddc said:

Hello

How can I install the english version of Vectorworks Interiorcad for student?

Go here: https://en.extragroup.de

Then, download educational version.

-

1

1

-

-

1 minute ago, Ride said:

Yes, I have. And I've tried to get in the habit of using that instead of the poly line tool. I'm getting old and old habits die hard. I've been using '5' for drawing a polyline for 12 years now. I'm going to try swapping the shortcuts in my workspace. See if that helps.

Yes, I know what you mean. "Can't teach an old dog new tricks", I guess. 🙂

-

1

1

-

Design Layer Order

in General Discussion

Posted

It's likely a sorting issue. Have you tried changing the sorting order of the numbers column? That should fix it.