-

Posts

1,331 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Stephan Moenninghoff

-

-

1 minute ago, Tom W. said:

Yes. Always

Can you send me the file?

-

This is the approach and departure path of the router. interiorcad created data for CNC milling from your 3D geometry. A bit like you can get lighting data from devices.

-

Have you enabled "3D Detail" in the OIP?

-

Fronts are not counted towards the overall dims because they have variable gaps to accommodate different hinges. They can also have different handle configurations. Fronts were included in overall dims with the old, "classic" cabinet object and it caused problems. Can't win in this situation.

-

3 hours ago, Tom W. said:

I'm trying to understand interiorcad Materials as well. I notice in my demo version of XS that in some instances where it previously said 'Material' it now says 'Board' which makes it a bit clearer.

I don't think there's any coordination with VW Materials.

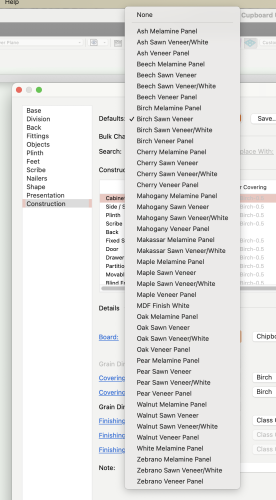

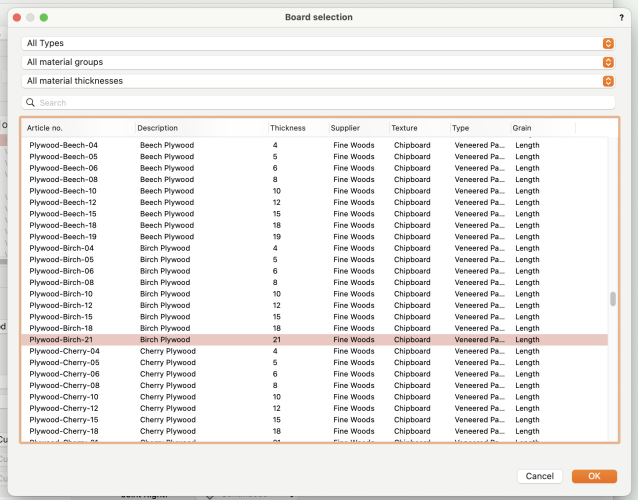

What I'm concerned about is that in your third video @Stephan Moenninghoff you say that if you have interiorxs you can't create your own materials so that means I'm restricted to the supplied defaults...??

Or do I create my own Boards/Materials in the 'Details' section + apply them to all the relevant Construction Groups? Do I have to repeat this for each new cabinet? Or save the first cabinet + adapt it for subsequent ones?

What do I do if I want to use a 24mm thick birch plywood board when the thickest offered is 21mm?:

Do I have to choose a different material but one which is 25mm (+ be happy with the 1mm difference + incongruous name) then override the texture?

Likewise am I restricted to the pre-existing material thicknesses for coverings I want to apply inside + outside? So if I want to apply a 1.3mm thick veneer I can't? I need to settle for 1mm.

Thanks to anyone who can point me in the right direction on this!

Am I in the ball park @Kevin K...?

Just a quick update. I'm too tied up with other stuff but I did create a substantial database of UK-specific materials, corner cabinets, as well as appliances such as fridges, cookers, hobs, sinks etc. These will be included in a future release with interiorcad so stay tuned...!

-

8 minutes ago, Chris Fleming said:

Ticket #5509

Thanks. I think you have heard back from them now anyway. Hope they were able to resolve your issues!

-

@Chris Fleming do you have a ticket number? I can try and reach out to extragroup for you.

-

1

1

-

-

Best open a ticket on https://extragroup.com.

Thanks!

-

3 hours ago, Raph said:

Did you try to take the symbol from my file and move it to a new file or an existing file of yours?

Yes, I did that. The only difference I saw was when pasting to a file that was set up to use imperial units. It changed the dimensions of the "Zarge" objects. But it did not break it. A video would help, I think.

-

I tried really hard to break it but couldn't.

Here's what I did:

Rotated the Marionette Object

Removed style and rotated

Created a new style from the unstyled object

Rotated

Everything looks good. Do you have any steps to reproduce? Maybe a short movie?

Thanks

-

8 hours ago, Raph said:

Hi Stephan

Thanks for your answerThis will solve the network display problem.

But the basic problem is more annoying.

in fact each time I import a new parametric symbol, I must to open it and go to the Marionette network.Otherwise the symbol remains invisible

Is there anyone who regularly uses parametric symbols and this happens to them too?

Is there a solution to this problem?Thanks

Do you mean a Marionette object when you say 'parametric symbol'?

I wanted to have a look at your file but it seems like the file is already broken. Do you have one that is still intact?

-

You can select all of the nodes in your network and then scale by the factor of your layer scale. That should return the network to a workable spacing.

-

1

1

-

-

I can confirm this. I am not sure if this is actually supposed to work since the native version seems to run without issue. But since this is an emulation, it may not be the same.

-

1

1

-

-

Hi @Fre , yes, it is not difficult, see here: https://www.extragroup.com/faq/ search for 'add new materials'.

-

1

1

-

-

@KenH Have you tried the Smart Options Display? It can be configured to do what you require with fewer clicks.

Maybe this will work for you?

-

2

2

-

-

Hi Bruce, it does align but with respect to the screen plane. 2D alignment works in x,y, 3D align in x,y,z. While 2D is the preferred mode for cardinal views (left, right, etc.), it creates the wrong result in an iso or perspective view. It is not always easy to identify where the 3d axes are in a cardinal view. That's why we need 2D align for these views.

This has nothing to do with your wish to improve the alignment process, which sometimes requires a locus. This used to be the case with 2D align before we had the right-click. So, I see a two-fold scope for improvement:

- Make it less cumbersome (and more discoverable) to override the normal align behavior's 'master object' (which is normally the object at the max coordinate of the alignment direction). This goes for 2D as well because the right click effect on the 'master object' is not known to many users.

- Make it easier to switch between 2D align and 3D align.

I would add my own 2c by saying that the entire alignment process is too protracted because it either requires a right-click (with a submenu, to boot) or, opening a dialog from the menu. Also, you must decide if you want 2D or 3D align. I think this could be simplified.

-

2

2

-

Gotcha. Like right-clicking a 2D object and aligning via the context-menu because that gives the clicked object priority. Yes, the 3D Align command does not seem to be available via right-click. You can place a 3D locus in case that helps because that takes precedence over everything else.

But I see what you mean. You don't want to use an extra object.

-

Bruce this is what Align 3D is for. Have you tried that?

-

The Vectorworks University is a good place to start.

Here is an 11-part course on interiorcad. Before you start with it, I urge you to complete the basic training for Vectorworks first though.

https://university.vectorworks.net/course/index.php?search=interiorcad-basic-workflow-2021

-

1

1

-

-

Vectorworks basic knowledge is a good foundation to becoming a successful interiorcad user. Get in touch with Vectorworks UK to get info on who can teach you. Once you have the basics under your belt, give me a shout and I'll teach you what you need to know for interiorcad.

A word of advice: as tempting as it might appear - avoid going down the easy path. Sketchup is great software but it is not for what you want. We did not choose Vectorworks randomly as a foundation for interiorcad 😉

-

Hi @sol117 interiorcad is perfectly suited to bespoke cabinetry because it combines the flexibility of Vectorworks with a state of the art parametric cabinet and powerful 3D custom parts. In fact the top UK bespoke kitchen designers and manufacturers are already switching to interiorcad because of its unrivalled combination of presentation/visualisation, costing/material takeoffs and CNC interface. With most modern CNC workcentres, you won't even need an additional middleware. You can output your 3D designs straight to your machines.

Don't worry too much about the learning curve. As you are correctly pointing out, interiorcad is used by the vast majority of companies in Germany now and we are only getting started in the rest of the world, with the UK being our first international stepping stone - with some happy customers.

You will master any software if it is suited to your job and interiorcad is, 100%. If you want me to put you in touch with some active users (there are now considerably more than the ones whose testimonials we are using on our web site), PM me. Also happy to answer all your questions in a Zoom call/demo.

Thanks!

-

3

3

-

-

10 hours ago, aref.aj said:

Is there an educational version of the Interiorcad program compatible with vw 2022

Yes there is. You can download it on https://extragroup.com

-

1

1

-

-

Did you enter edit mode from a sheet layer?

-

1

1

-

-

Just SVG import would be nice. Never mind EPS. Not sure about what you mean by lack of accuracy. SVG is quite accurate in my experience.

-

2

2

-

InteriorXS question re Contour 3D tool

in 3rd Party Services, Products and Events

Posted

Ok, I see. You want this:

That's pocket. You need the full version of interiorcad for this to work. interior xs does not support it. But your workaround with a humungous router bit works, of course.