-

Posts

1,330 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Stephan Moenninghoff

-

-

2 hours ago, Ride said:

I don't understand. Why is the implied bezier curve with the poly line tool is so eager to activate?? And why is this a feature at all? There are options for different curves in the mode bar, if I wanted something other than a straight line, I would select a different mode. This "feature" drives me crazy. Sometimes the software needs to get out of the way so you can get some work done.

I think what you are seeing is when you hold down the mouse after you have inserted a new vertex. If you click fast, this may happen. It's a feature that allows you to change the vertex type to Bézier without switching modes. It's been around forever.

-

17 hours ago, javitojavitojavito said:

Thanks Stephan apologies for the delay in responding. I think the issue was caused from copying and pasting between files all the time. I updated my EDU vectorworks to the latest version and things seem to be working regarding duplicates now. Also replicated the same design without copying and pasting cabinets between files and my file is not bigger than 50mb. Made a bunch of custom connectors and seems to be working fine now.

The problem with the connectors and the groups seems to be just when the cabinet is nested in at least two groups if you keep a single group structure connector placement seems to be working well.

BTW I found that the purge command has a coincident duplicate option. Handy if you have placed the same connector on the same place twice!

Thanks again! So far I am enjoying it, it requires a bit of structure but is far better solution than we have used in the past!

That sounds good. Thanks for confirming!

-

On 4/29/2021 at 11:18 AM, javitojavitojavito said:

- Performance: I made a test with 8 cabinets, 12 drawers and a couple hundreds cabinet connectors (cabineo and screws) and things are slowing down. Testing in in a i7 with windows, 16Gb and Radeon RX 580 8Gb. Full quality OpenGL and shadows. File is now 130 Mb. Which system would be recommended for these type of files? Maybe there are some optimization routines that should be applied?

I would like to have a look at that file as well please. From what you are describing, it does not sound like it should be slow. I might find out why it seems to perform poorly though.

On 4/29/2021 at 11:18 AM, javitojavitojavito said:- connector placement: I have nested groups for different cabinets so when double click I can isolate parts of the model and work faster. I found an issue when inserting cabinet connectors on nested groups, the connector wont align properly on the grid. See first image below. Funny thing is that if I copy the cabinet to an empty document it will allow me to insert the connectors as expected. See second image. So I ended coping and pasting cabinets back and forth to insert connectors.

This issue should be fixed in the upcoming service pack. Thanks for reporting!

On 4/29/2021 at 11:18 AM, javitojavitojavito said:- Coincident duplicates. When creating cutting list I am getting far too many connectors and fittings counts. I checked that there are no elements one of top of each other but there might slip out something when cutting and pasting. Is it possible to remove coincident duplicates in order to get those listings correct?

I am not aware of a script to check coincident duplicates but I checked your file manually and the counts seems ok. I also created an empty file and inserted the same connectors you used and the count seemed to add up. Did you see this in the file you sent me?

On 4/29/2021 at 11:18 AM, javitojavitojavito said:In summary I find Interiorcad intuitive and powerful but before presenting the tool to students next semester I would like to check that it would simplify their design workflow and reduce errors when cutting things on the CNC.

That is our mission and it should do just that 🙂

-

2

2

-

-

Can I have a look at your file? I have an idea what's happening.

-

You need to use the cabinet tool and then choose the saved preset from the mode bar. It doesn't work if you insert from the resource manager.

-

Thanks, @Marcel Ostendorf for chipping in!

Here's the direct link to the FAQ: https://en.extragroup.de/question/why-do-some-of-my-own-custom-screws-change-position-when-a-cabinet-is-reshaped/

-

1

1

-

-

Hi Zeno,

they are. As for all machinings that we model in interiorcad, you need to hide the class in 3D. See this FAQ:

https://en.extragroup.de/question/why-are-my-millings-visible-in-hidden-line/

-

1

1

-

-

Go to View -> Class Options. It should be Show/Snap/Modify Others. Is it?

-

1

1

-

-

Hi Zeno!

We do not show the profile currently in the part layout. We'll need to add that. Argh, yuck, we messed up the texture mapping badly for the profile. I'll need to get someone from engineering to look into that.

-

1

1

-

-

12 minutes ago, Ride said:

Following along here. A quick question about interfaces. How well does InteriorCAD interface with Biesseworks?

It does. We supply CIX. We also interface with the more modern BSolid, also by Biesse.

-

On 4/5/2021 at 3:03 PM, dminzner said:

Playing around with cut lists I see they come up metric. Is there a way to have them Imperial?

I have Interiorcad set to imperial.

Our plan is to get up and running 100% on the software while we wait for our machine to arrive.

We can take advantage of cut lists immediately so our guys don't have to waste time pouring over drawings.

Not sure why they come up metric. When you first installed interiorcad you were asked to choose. Did you choose imperial then as well? Can you shoot me a document where you are getting metric units?

-

19 minutes ago, dminzner said:

How about labels? Will we be able to barcode parts or is that a Homag thing?

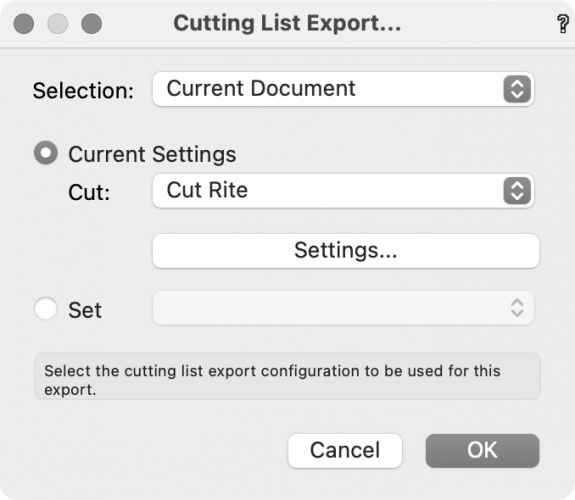

Sure you want a barcode? I think QR codes are the preferred choice now but up to you. Both are no problem. Make sure you get "Cut Rite" for panel optimising. It should be supplied with your machine anyway if it's capable of nesting. We have an export for it so you get all your edgebanding information across as well. Cut Rite will create the graphic code from the information you get from interiorcad.

-

9 hours ago, dminzner said:

On Tuesday we are looking at a new Homag Router.

Homag uses Woodwop as their machine software. We have been interfacing with Woodwop for 20+ years. No worries there. Will you be looking at a nesting-based or a point-to-point setup?

-

3 hours ago, dminzner said:

We are new to Interiorcad. Currently we are 3D modeling all our cabinets and then manually creating cut lists etc.

Our goal is to use InteriorCad to draw all our cabinet boxes and go straight to a CNC router.

All of our projects are 100% custom and all our shop drawings are reviewed by a designer or architect.

Many times architects will have us make very minor changes such as increasing or decreasing a cabinet by fractions of an inch.

In theory we may have a cabinet with a vertical divider in it that needs to be moved a 1/4". Does this mean we need to completely redraw the cabinet to the new divisions for is there a way to adjust vertical divisions AFTER the cabinet is drawn?

That's kind of the point of interiorcad 🙂. It's very easy to do. You can use mm/inches or percentages or ratios even and you can define variable cells that will stretch and shrink. Have you done the tutorial in the Vectorworks University? It explains how it's done. Let me know if you have questions.

https://university.vectorworks.net/course/index.php?search=interiorcad-basic-workflow-2021

-

Ok, you need to turn off the contour class in the viewport. We can hide the contour in openGL and wireframe (we have assigned it a zero line thickness and a texture with 100% transparency so it does not show up but you can still select it) but not in hidden line.

-

6 hours ago, Ride said:

@Stephan Moenninghoff - can you tell me how to notch this partition? I have a sink going here and want to show the cutout.

Of course I can tell you: use a Contour 3D object. Please make sure you have ticked the "3D Details" checkbox in the Object Info Palette of the cabinet object. The notch will not show up otherwise.

You can skip the "convert to polygons"-part if you're not bothered about CNC output. I do that to get rid of the extra side. It is not required.

6 hours ago, Ride said:Also - how is the InteriorCAD manual coming along? I asked some time ago and I think you said it was not far away.

Yes, the tutorial on the Vectorworks University. Glad you mention it. It is done: https://university.vectorworks.net/course/index.php?search=interiorcad-basic-workflow-2021. Enjoy!

We have also updated the interiorcad manual: https://conf.extragroup.de:8443/im/latest

-

2

2

-

-

You cannot use a hash placeholder when you use proportional division. It is not logical. Which proportion of the total height should the hash occupy? You have ratios of divisions so if you have a total of four boxes, you can input 1:2:2.4:3 but you cannot use a hash.

You can use a hash if you use percentages: 30%;30%;10%;# will work for example.

-

1

1

-

-

Happy to have a look what might be happening. As with all support questions, you can dramatically expedite the whole process by including a document or messaging me directly with it.

-

1

1

-

-

-

1

1

-

-

Marionette placement appears to be broken in the 2021 cabinet. Thanks for the report, I have filed a bug.

-

1

1

-

-

You need to check "Ridimensiona oggetto" and then make it stretch. You don't need to use a Marionette any more for this, did you know? You can use two rod bearings (as blue symbols) and an extrude (also a blue symbol) and interiorcad will reshape the extrude to fit the width. No clothes and no clothes hangers (yet), obviously...

-

1

1

-

-

-

2 hours ago, Daisy Y said:

Thanks Nicolas! The first point helps a little, it lets me edit the frame that goes round the outside but it doesn't allow me to create a detail style of door I can apply to different units (ie, with mini sub rails that divide up the door creating a sort of grid look over the door). Perhaps this isn't a possible feature available yet?

Can you show us what you have in mind? Maybe we can integrate it or maybe you can already do it.

-

@Daisy Y I have just finished a 11-part tutorial to get you up to speed with exactly how these things are done. It will soon appear on a screen near you. Stay tuned until mid-March for more news on this.

Stop it with the implied bezier curves with the poly line tool!

in Troubleshooting

Posted

If you want to draw corner vertices only, you can use the polygon tool. Will that not work?