-

Posts

3,096 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by shorter

-

in a word… practice! oh, and patience oh, and care… like cameras models never lie. takes 3-4 projects before you get it close to how you would have drawn it (unless you are like some users of another software that shall remain nameless who simply do not seem to care). this is why for very good reason they say never wait until you biggest project to ‘do bim’. I would add to that never wait to be told. bim under duress results in the same result as does bim without a plan where you have no strategy as to how you are going to model.

- 4 replies

-

- elevations

- linework

-

(and 2 more)

Tagged with:

-

Architectural Fees - how to get more $$ upfront?

shorter replied to Shortnort's topic in Architecture

Tend to find clients are happy to pay (more) when they can see they are getting a quality service. I don’t think BIM has anything to do with it. bIM is just another way of getting your work done. If anything they will be expecting a discount because they have probably heard things can be done faster so be careful what you wish for! -

Architectural Fees - how to get more $$ upfront?

shorter replied to Shortnort's topic in Architecture

@jeff prince I must admit I thought the question was from a recently qualified architect not one of 40 years practice. Not sure it warranted that response. -

Door Dimensions and Tolerances

shorter replied to shorter's question in Wishlist - Feature and Content Requests

ps Having set the SO of a double door, it would be good if the door reported the leaf size as 826, not 1652. Or conversely, set the door to double door, and then set the leaf size of each leaf i.e. 826mm, and this sets the correct SO for a double door.- 1 reply

-

- 1

-

-

Just building a content library for a few clients at the moment and have encountered the perennial complaint about the way doors work, and the fact we cannot add tolerances between door and frame. For typical door tolerances take a look at http://www.leaderflushshapland.co.uk/Integrated-doorsets/Technical-Resources/Technical-Guide/Design-Considerations/Tolerances-Dimensioning If we set the 7mm tolerance between frame and structural opening, the frame size is correct, but the leaf size is wrong. So if we adjust the overall frame size, and increase the tolerance between frame and SO to 10mm, the overall frame size is obviously going to be wrong. We base our doors on leaf size. leaf size + 2 x 3mm + frame thickness = doorset size. doorset size + 2 x 'shim gap' as Vectorworks calls it = SO. Without being able to specify the 3mm gap between leaf and frame something ends up being wrong in the schedule, usually the overall frame size. I know this has been discussed before ad nauseam, but thought I would chime in again. The problem is even worse in a double door where we need to allow a gap between door leaves in order to generate a schedule with the correct leaf size. 2 x 826mm leafs, 4mm gap at the meeting stiles, 3mm gap between door leaf and frame. If we set leaf size to 2x826, the overall frame size is wrong if we enter the correct width and compensate in the 'shim gap in order to report the correct SO. 7mm shim gap + 32mm frame + 3m tol. + 826mm leaf + 4mm tol. + 826mm leaf + 3mm tol. + 32mm frame + 7mm shim gap = SO Overall Frame size is SO - 14mm. We have to model 12mm shim gap + 32mm frame + 0m tol. + 826mm leaf + 0mm tol. + 826mm leaf + 0mm tol. + 32mm frame + 12mm shim gap = SO Overall frame size is SO - 24mm.

- 1 reply

-

- 3

-

-

The current behaviour of 'paste in place' is to deliver the objects copied relative to the coordinate system defined by the user origin, or if there is no user origin, aligned to the coordinate system defined by the internal origin. Sometimes, we want to copy from a file containing a user origin but want to paste relative to the internal origin. An option to do this in the paste in place command would be useful. As would 'copy with base point' where you select objects, define a point in the source file, copy, click on a point in the recipient file, and paste and the objects paste relative to the click point. There are obviously workarounds but each is an extra step compared to the above and involves a manual move of the data after placement or a temporary cessation of the user origin, both of which we would rather avoid.

-

Wall component graphic behavior changes when part of a symbol

shorter replied to EliM's topic in Architecture

In a 2D workflow unified view is probably unnecessary, but would be a bit of a pain in 3D. This sounds like a bug to me. -

Wall component graphic behavior changes when part of a symbol

shorter replied to EliM's topic in Architecture

I shall test as we have a lot of projects with walls inside symbols… could be a problem if this does not work as expected. I often find that some plugin objects do not update very readily when inside a symbol. -

Wall component graphic behavior changes when part of a symbol

shorter replied to EliM's topic in Architecture

Which version of VW is this? -

Buying - Selling licenses Info

shorter replied to JuanP's topic in Buying and Selling Vectorworks Licenses

Is this true? Of course the UK is stupidly not in the EU any more, but I thought the deadline for new perpetual licenses was 31 December 2023, and that Service Select is no longer available because it can only be purchased with a perpetual license unless you are currently a service select customer and looking forward to your renewal. -

It should be like a roof plane. If you look at a ramp in section, it generally has constant thickness, like a roof finish. So, if the ramp could be like a roof we could 'style' them. We use the roof plane at the moment, but have to then draw the ramp arrow, which is a bit of a pain, but it's constructionally correct and if I am not mistaken, on a BIM project, that's the name of the game.

-

ISO 19650 Compliance - Revisioning

shorter replied to shorter's question in Wishlist - Feature and Content Requests

The frustrating thing is that non-compliance in vectorworks is far easier than compliance! -

Could this be a document setting rather than an application setting? It currently resides in the application preferences.

-

IfcClassification - The use of - and / in the classification name.

shorter replied to shorter's question in Troubleshooting

I am talking about the classification fields that are standard in every standard ifc pset. I am not talking about a new pset. for example, the Wall has Cost Index fields that map to the Classification Name and Classification Reference fields in the ifc attributes of the wall, eg Uniclass2015 Ss_25_10. if I enter XX-YYY in place of Uniclass2015 it does not export. XX/YYY does. The issue is that we have been told to use the hyphen and I am not sure the hyphen is a permitted character in that field or if it’s a vw bug. -

Materials - Percentages...

shorter replied to shorter's question in Wishlist - Feature and Content Requests

There is a desire to report the volume of PPC for the purposes of Embodied carbon calculations… -

Materials - Percentages...

shorter replied to shorter's question in Wishlist - Feature and Content Requests

Circular Hollow Sections -

Materials - Percentages...

shorter replied to shorter's question in Wishlist - Feature and Content Requests

Polyester Powder Coating… I have of course suggested a homogenised approach as per galvanised steel but they would like to differentiate the steel from the finish. -

It does not appear that we can enter percentages of material to any greater accuracy than 2 decimal places. If I have two materials in the proportion 99.999999% and 0.000001% it rounds to 100.00% and 0.00% but strangely does show one of the materials as having a volume of 0.00001m3 on a 10m x 10m x 10m volume but shows the other material as being 1000m3, and not 999.99999m3.

-

IfcClassification - The use of - and / in the classification name.

shorter posted a question in Troubleshooting

Apologies if I have posted this already. If I enter XX/YYY as a classification name in the ifc classification pset, I get XX/YYY listed as classification in the IFC when viewed in Solibri or BIM Collab. If I enter XX-YYY, I get nothing. Is this a Vectorworks bug or IFC semantics? -

Uniclass 2015 Classification Tables - Out of Date

shorter replied to shorter's question in Wishlist - Feature and Content Requests

I am sure materials is not the only place where a lookup of the correct classification would be useful. When creating content, it would be great, for example, to have a lookup in the Wall Data Cost Index fields, or the Classification field in the IFC property set, or when mapping classes, or in the Data Manager....- 2 replies

-

- iso19650

- uniclass 2015

-

(and 2 more)

Tagged with:

-

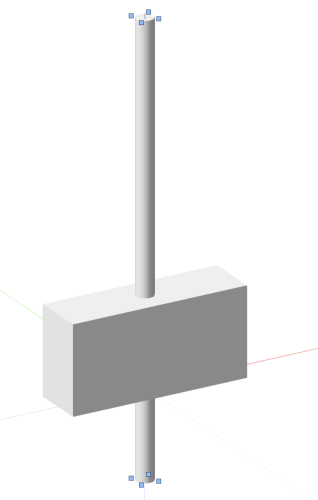

Here is a very simple example of what I am looking for with the Trim Tool. I would like to simply use the Trim Tool to remove the lower section of the cylinder that hangs below the rectangular geometry. I would like to do this with one click. I would like to not have to select anything. I would like to not have to create another object. I would like to not have to go into another view to use the split tool. If these were 2D objects, I would simply select the trim tool and it would trim the 2d object to the nearest object. Not so in 3D. Yes, I know there are other tools that would do this but what I wish for is the Trim Tool to do this with greater ease and efficiency. Trim Tool will throw up an error...

-

Dear Vectorworks Would it be possible to issue up-to-date Uniclass 2015 classification tables with every service pack in future? Table Pr for example was updated in April 2023, and is now on revision 1-30. The version that ships with VW is v1-19. For those interested, the csv that works with the lookup classification tables in the materials properties dialog can be found here https://www.dropbox.com/t/195w5kmiIoYa4A2Q I have saved it as a Dropbox link because I cannot upload csv files to the forum. Save it in the Libraries/Defaults/Classifications folder in the application folder or workgroup folder. Note to Vectorworks... These tables now include a 'Sub-Object' column and this throws Vectorworks off the scent, and the descriptions that we rely on to find the correct code are missing. The csv above has the sub-object column deleted. Thanks.

- 2 replies

-

- 1

-

-

- iso19650

- uniclass 2015

-

(and 2 more)

Tagged with:

-

The split tool only works in one plane. Which is fine in this instance, and that's what we used, but when another 3D object meets a more complex geometry...

-

Solid Subtraction on Mulitiple Solids

shorter replied to shorter's question in Wishlist - Feature and Content Requests

The columns need to remain as individual columns. I suppose it was semantics. The command says ‘subtract solids’ but doesn’t. It only subtracts one solid from another. the split tool only works in one direction and would not help if the wall, for example, undulated. Section Solids works once the geometry is aligned correctly but was overlooked.