Nathaniel.C

Member-

Posts

23 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Nathaniel.C

-

Label Legend - Size of container type

Nathaniel.C replied to Cristiano Alves's topic in Entertainment

Try using "absolute address" -

Label Legend auto spacing based on different fixture sizes

Nathaniel.C replied to Nathaniel.C's topic in Entertainment

I've had a play with the above but it still seems to space them based on fixture size or breaks parts like "flip left or right" if you force align. -

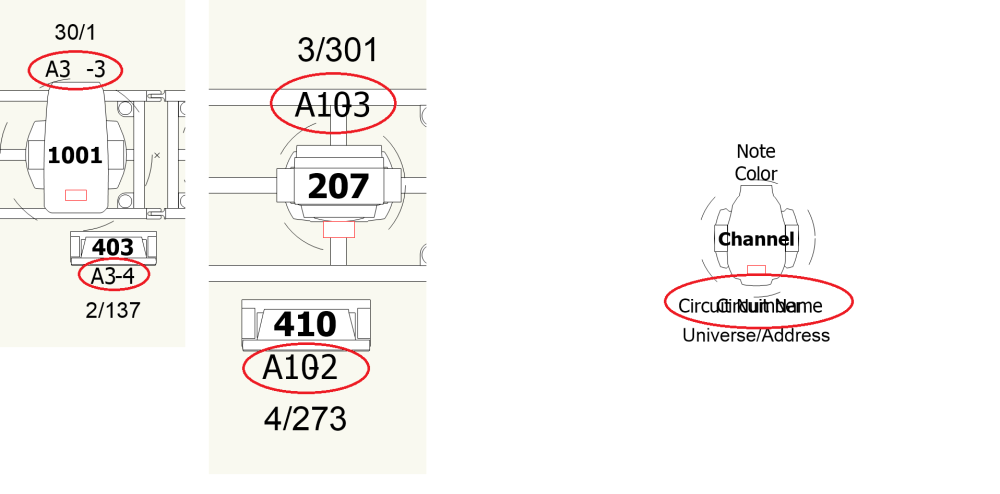

I've been having this issue from around VW22 after an update, where my label legend auto spaces out based on fixture size. (Image attached below, First image shows the spacing issue.) It never used to do this and then suddenly started doing it. Is there a way to stop it from spacing out automatically? Short of making 3 different label legends for different sized fixtures. I'm using Circuit name followed by Circuit Number.

-

pm sent with file.

-

That is unfortunte, I have two files that do it currently and they are extremely large and detailed. with a bunch of the loci imbedded in symbols and some on the same class by the looks of it. which is definately not an easy task. There must be some way to fix this, as it has happened quite randomly and not when i first started the file. Also the draw lines arn't infinte.

-

Thanks Pat, I've run the script and it made no changes to the wireframe render. Script compiles correct.

-

I've had this issue come up a couple of times now and it makes it extremely hard to work in a 3d space, as you can see the symbols explode out like the loci is massive and as you pan they spin also. Anyone experienced this or know why this is happening?

-

Thanks Peter, as you can see all the above posts are pre-october. Using the new library now, looking forward to being able to use the braceworks data also.

- 12 replies

-

- feature request

- braceworks

-

(and 1 more)

Tagged with:

-

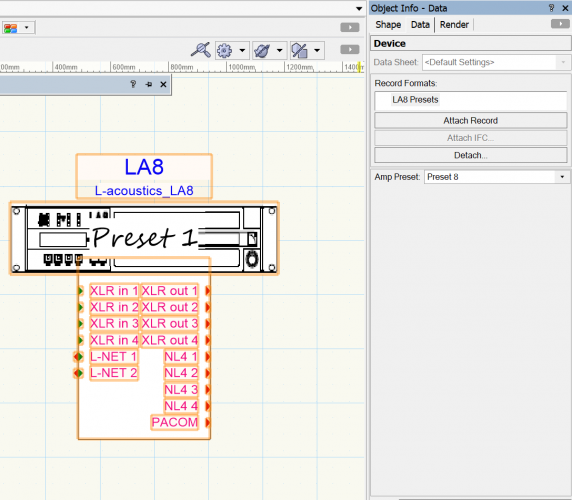

I'm not really sure where this question should go, I'm trying to attach a popup record to a Symbol but have the label show the popup selection, I've had a couple of ideas on how to achieve this but none of been a one size fits all solution. Currently linking text to record will only display the first item in the record as it has no relation to the symbol popup selection. If i use a data tag it means everytime i add the symbol i would need to add the data tag if i'm not mistaken?

-

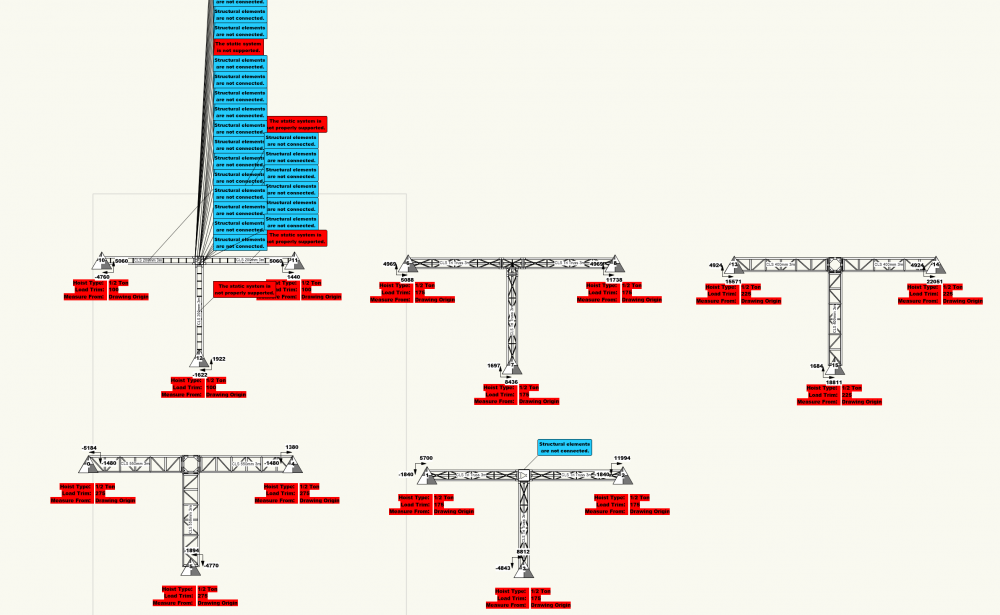

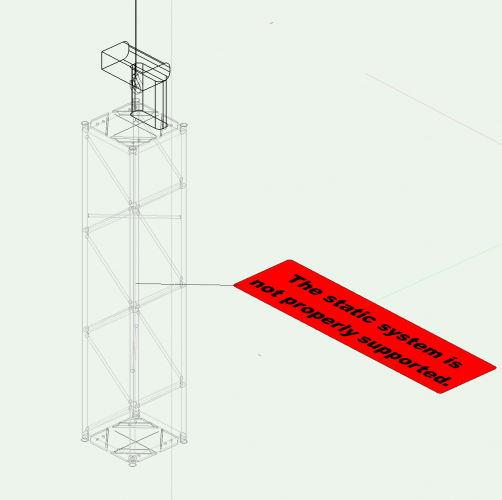

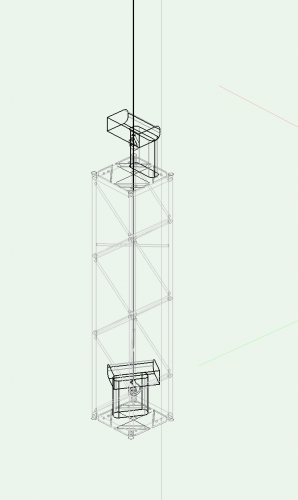

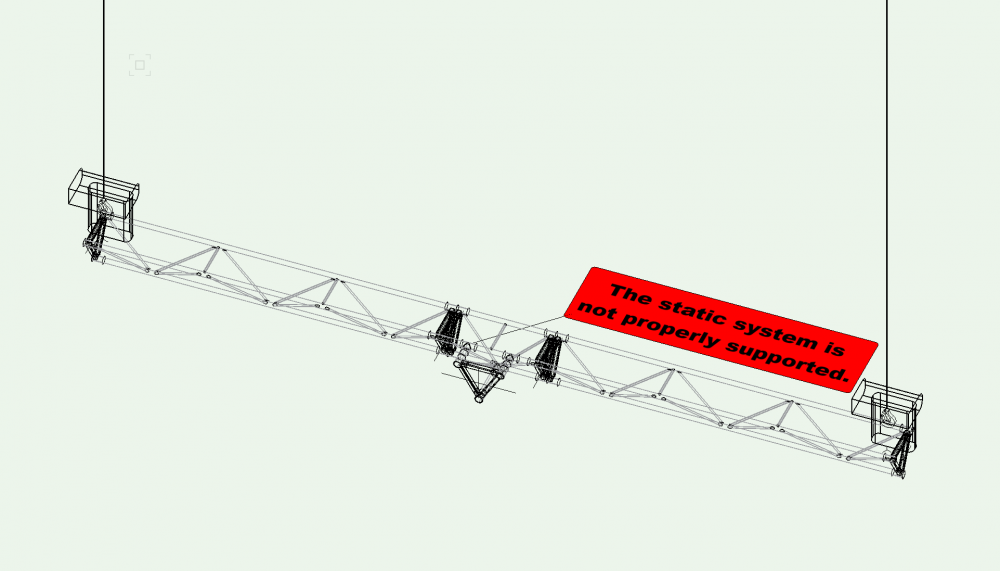

I'm following you with the errors that i need to fix up, but i still don't understand then why does the the 400 and 500 not error out where as the 200 and tri does??? I just did a quick edit and matched the type field for the 200 to the connectable and adjusted the 3D geometry and still have the same issue with the 200 but not the others.

- 12 replies

-

- feature request

- braceworks

-

(and 1 more)

Tagged with:

-

I don't believe you are correct, as you will see the 500 box and the 400 box don't have the errors yet all have the same type, connectable field setup like the 200 box/tri truss and the cube is larger also.

- 12 replies

-

- feature request

- braceworks

-

(and 1 more)

Tagged with:

-

Bump PM sent and no reply.

- 12 replies

-

- feature request

- braceworks

-

(and 1 more)

Tagged with:

-

PM sent

- 12 replies

-

- feature request

- braceworks

-

(and 1 more)

Tagged with:

-

These are my own symbols with no cross section data currently. With the T section i did some further testing and did find it did exactly as you mention where once you add the third piece it is happy. However with Cubes is a different story, I'm getting mixed results and not sure if its something with my symbols or something else. As you can see it is happy with the larger cubes but not with the smaller ones. (this was run without our braceworks licence enabled just to do a system check) Happy to PM you the file, just let me know.

- 12 replies

-

- feature request

- braceworks

-

(and 1 more)

Tagged with:

-

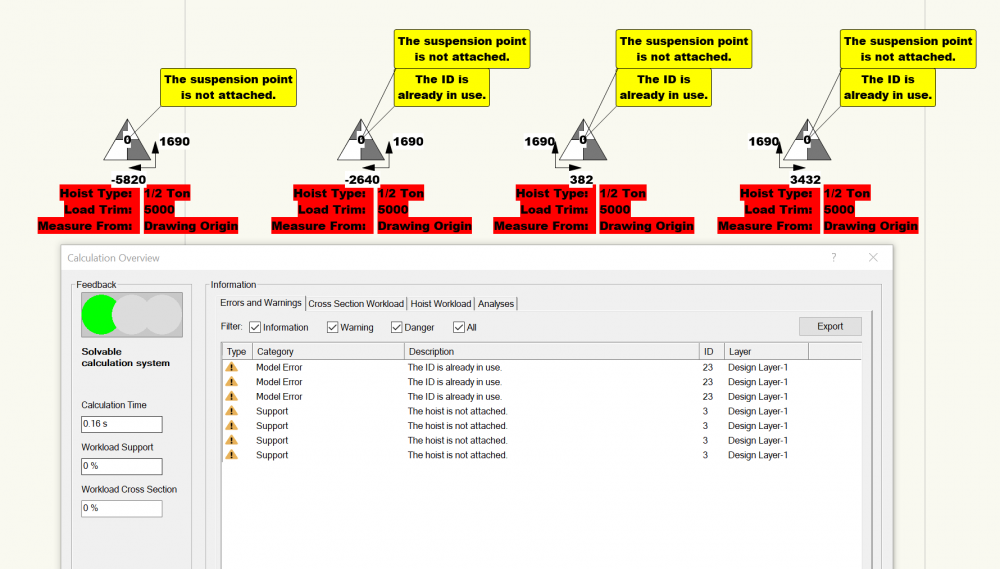

Thanks for the update, If Hoist ID is not a UID for braceworks then why does it flag as a "warning" when you run a calculation? Should it not just ignore it? If the UID was the same then i would expect this warning and "reset Braceworks ID" to function as it does with a lighting fixture. If a lighting fixture has the same channel braceworks doesn't flag this, but when a lighting fixture flags this same error/UID restting braceworks ID's fixes it and the error no longer persists. I understand it doesn't effect the calculation, but its such a frustration if you mirror an entire rig and when you run your calculation a million little yellow pop ups appear and errors in your calculation for a field that doesn't effect the calculation. As mentioned above we don't even use this field as it is an integer field and doesn't allow for alphabetical letters. (we use Hoist Label instead) I like the sound of the auto numbering and look forward to this!

-

So after playing around Reset Braceworks ID's works for lighting fixtures with this, but not Hoists. As mentioned a script was written for the Hoist renumbering.

-

Identical result. I am aware you can use the spotlight numbering tool, but its yet another step to do to get rid of an error message.

-

This hoist ID is the issue. Every time you duplicate a hoist the ID stays the same and flags in Braceworks and you have to go through and change them, this field doesn't accept letters thus we don't use it to identify Hoists and positioning and use Hoist Label instead. This field should just auto increase on duplication so as not to flag everytime.

-

Negative it doesn't

-

As every hoist must have a unique ID for braceworks i don't see why it should duplicate. We use the "Hoist Label" to differentiate between hoists and for location identification. So the hoist number is purely for braceworks and should always generate a unique number. A script sounds like a good temporary solution.

-

When duplicating a hoist or piece of truss it copies the ID and flags an error, can this be set to automatically create a new unique ID upon copy / duplication so as not to cause this every time. Same with mirror tool if you want the same truss setup on the opposite side of a room why would you redraw the entire thing when you can just mirror?

-

I've run into a hiccup where if i want to hang a truss vertically from a single motor Braceworks defines it as not properly supported and requires the second motor to be attached. As the truss is hanging vertically it is sufficiently supported. Same as if using a T or X join peice of truss, if all connection points are not connected it believes it is not supported.

- 12 replies

-

- feature request

- braceworks

-

(and 1 more)

Tagged with:

-

Wahlberg Winches would be nice also, there is one symbol already made in the library.