AStein

Member-

Posts

58 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by AStein

-

Alright, thank you. If I can't think of something clever I'll go ahead and make 20 different ID tags, one for each beam and keep them in my boneyard file.

-

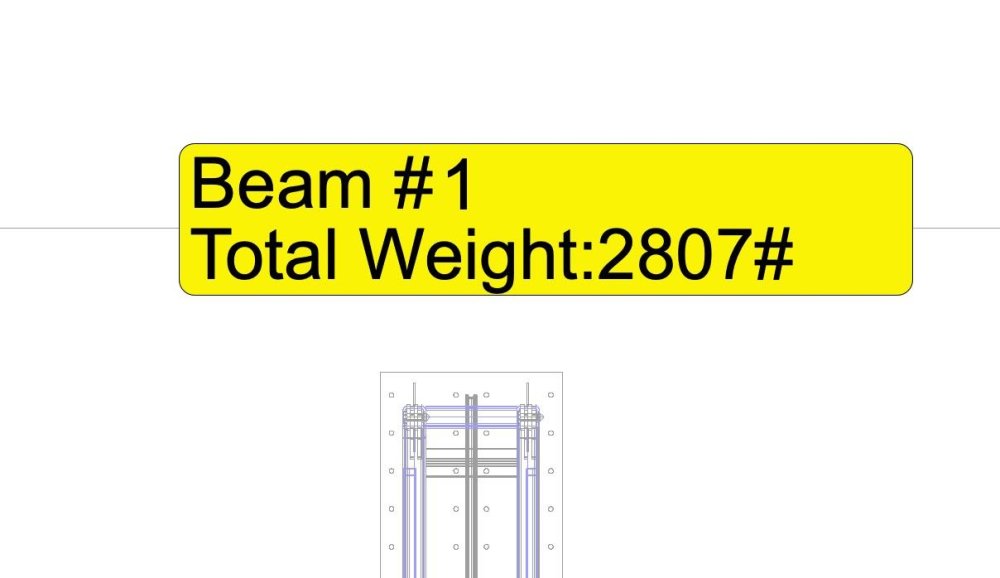

@Pat Stanford Worked like a charm Pat thank you. I ended up doing a ROUNDUP function instead of TXT to keep it as a number, but I don't know if that'll matter or not at some point. My question now is if there's a way for me to pass the user entered tag field into the formula WS coordinates? So for beam 1, the worksheet cell I want to grab is B4 and add 3 to it, which will point the tag to the right cell. #WS_CONCAT('Beam Weight Calculator':B4)#'#' That's my current function #WS_CONCAT('Beam Weight Calculator':B"Beam # + 3")#'#' And this is the type of thing I'd like to make work. When I put single or double quotes around the characters in the cell coordinates if breaks the function so I'm not sure if there's a function to pass text in or something?

-

Hello! I have a big, complicated worksheet to calculate individual beam loads for me and I'd like to represent this nicely on my drawing. Is there a way to visually and dynamically reference an individual cell from a data tag? My backup plan is to create a new worksheet for each beam because I can reference worksheets from other worksheets, but this is very cumbersome. Thoughts? Thanks ahead of time!

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@Sam Jones You know Sam, you've pitched your software for enough of my problems that I'm really curious. I have two more avenues left to try before I buy another VWX tool, but I wanted to say that I admire sales acumen. -

@klinzey Copy... I think my workaround will be to have a special layer where I import everything I want to calculate, then dump the hoists into to rig layer after they calculate. They seem to retain their numbers if I do that. @Stefan B. You know, I've really run into headaches with that. if it were just my office and/or I was working with the same people a lot more I might cement that workflow, but using a dropbox folder that I set up for them is almost too much of an ask half the time... I actually run into this sort of VWX wrestling match a lot. I'm on a project right now where I'm integrating and was excited because other departments seemed on-board. LX said he used VWX symbols and truss so I'd finally get to use Braceworks as intended rather than replacing everything with BRX-friendly truss, manually adding up the lights and doing a UDL... Then i import his layer and it's all customized symbols from enough versions ago that nothing works or connects... It's kind of my larger frustratioin with Vectorworks... In theory, these are some awesome and easy tools, but they're too engineered. Like how we still can't hang a torm from a single hoist?!?! Literally every show I do...

-

Connecting a single hoist to a vertical truss

AStein replied to Mathijs van Ommen's topic in Braceworks

Is this on a list to ever get fixed? I've got torms in almost every show I do and I can't throw off my truss and hoist counts wrestling with workarounds. -

Hey guys. Is there a way to get hoists, truss and instruments to connect and communicate with each other on separate layres? Basically, the workflow is this: I create a dropbox folder where each department gets a sub folder and a master file. Then we all reference each other with reference layres. I would love to keep all the hoists on a hoist layer rather than having to import other departments layres then work inside their layres with my rigging stuff, and then having everything break when they make a small change that I then have to re-import. Thank you.

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@msharonThe Life-Size data tag is is a really interesting idea, thank you. The pitfall here is that I have a show coming up with a bit over 300 hoists so I'd need a way to automate the layout and pagination. Does vectorworks have anything like that? -

New File attached. One step closer. If I drop a "power in" component on the hoist symbol definition then the distro recognizes it and shoots a cable over there and/or the cable tool acts like it should. But if I move the hoist, the cable node wont follow like it does with a lighting device. I have a lighting device on this file that uses my custom "hoist cable" to make sure it wasn't my distro or cable, but it seems to like them just fine, so I think we're down to troubleshooting the hoist now. "Consumer" on the hoist doesn't seem to work, it likes the "power in" component. I also tried converting the hoist symbol to a lighting device, but it didn't let me. Cable WIP.vwx

-

@jcogdellAttempted file attached. So, I went into the cable XML file and made some hoist cable. Changed the symbols on the distro to "consumer" Everything seems to match. I can get the "end" to lock onto the hoist, but it still doesn't like the distro. Thoughts? Cable WIP.vwx

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

Interesting. -

@jcogdellCopy, thanks Jesse. I'll give that a try tomorrow morning.

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@Sam JonesYeah, one of my guys got really interested in trying to find a 2" wide soft tape and putting labels or tabs on it. I think truss tape alone for layout would be problematic because of how fragile it is, but something like that would look slick... Maybe a roll of vinyl? I don't know, I don't really have an issue with layouts done the "old fashioned way". The stickers are more to serve one-offs/festivals when there's just too much data to scribble with chalk effectively... Also, it tooks great when the bullseye of each sticker is my client's event or logo 😉 @Mike RockOhh! That's really clever, looping through to look for what's close and 2nd closest. I should really play around with LLMs eh? But that is a rough version of what I'm looking for. I agree that rigging is super-segmented and informal. I think one of the major issues in my market is that it's nearly impossible to run a vendor-based rigging company since other vendors just decided to buy their own truss and hoists and generally undercut what it's worth to rent in order to better sell their higher-margin instruments. Then, they can never get the best riggers to sign on because the mindset and pay expectations between departments is so vast... Anyway, that's why we're all over-opinionated, entrepreneurs who each have our own dogma based on how we came up in the industry... It's not great. But that's also why we're often frustrated with how closed-off Vectorworks can feel. -

Normally, like with lights or when connecting two units it shows up on its circuit in the OIP, and yes, they do light up red when I use the cable tool. I van also tell they're not connected because the node doesn't attach to the object and move with it. See, I'm stuck between a rock and a hard place... I have a series of Google sheets with a bunch of javascript underneath that do a lot of organization for me. But now that I'm growing into a business that manages others, it's way too complicated and prone to human error. People hire me to draw their tours because I organize data better than the next guy. My system is good, but if I'm going to expect others to use it, it needs to be simpler. Like: my template and my boneyard, rather than complicated instructions and links to little apps I've made. Basically, I either need vectorworks to work or I need to spend a ton of time coding and building my own system. I have a 4-month-old and a two-year-old so... Given that vwx, has been making major steps to modernize itself in the past few years, I've decided to build out my system in vectorworks.... but it's so obtuse sometimes, like this cable thing. Rigging is always left mostly done...

-

@Stefan B.Thank you. No hurry. In the OIP of the distro there's no connections to choose from.

-

Hey there. I found a couple other topics that described how to jury-rig an LX breakout to use as a hoist distro, but I can't quite get it to work. Simplified attempt attached. I edited the electrical components inside the symbol definition to be SOCA-7. The hoist cable in the OIP of the hoist symbol is SOCA-7 and the cable on the cable tool is SOCA-7. I click the distro, then I click the hoist... And nothing. The distro, hoist and cable all act like they're not connected. I know that rigging-related electrics are on the to-do list for this upcoming update I've been reading about, but I can't see why my workaround here is failing. motor connection.vwx

-

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@jcogdell Thanks, I'm glad it might be useful. I've been teaching VWX to riggers lately, formally and informally, so I get to hear a lot from the community. I plan on formalizing my VWX knowledge more so that I can be sure I'm teaching a good workflow, but things tend to get busy... had to miss LDI because I've got a new baby at home and she needs all the tutorials 😛 -

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

I currently run Production Assist and I might describe it as "too much" But (aside from the loading tools and influence lines) I really like it's selection tree and sticker printing tools. What I think we all miss from the Legacy Hoists, even though it was a bit of a menu dive, was being able to stick the Hoist ID in the center of the hoist symbol easily and displaying/maneuvering the data (usually just the load for engineer submissions). I use data tags now and that's fine, but it's just a little bit of extra clunkiness where I'm like: why did this get worse? Another struggle is piercing the hanging position veil for gear counting. I just stopped using them because it makes counting truss in reports a pain. I feel like this concept is good, but if I've got a literal mile of truss to count and it's mostly in hanging positions. Yick. I love that BRX/PA auto resolves spans into hoists. This is the killer tool and what riggers seem to want access to more than anything, but $2500/yr is just not worth it unless I can claw some of that money back from clients via volume. For gear, I currently run a spreadsheet where I tell it what's in a system then multiply that list by the systems present, like: "deadhang" = x3 5/8" SHAX, x1 6' GAC x1 5' 3/8" WW, x1 Burlap... I have a Data Record and custom hoists that help me integrate into my format, but it's still copy paste. I see that there's some sort of virtual hardware thing going on in VWX right now. Maybe it's awesome? But I'm not really there yet. I'd love to do this inside VWX. I print floor stickers for most one-offs. Used the little bit of Javascript I know to build a script under google docs. I currently see no good way to do this in VWX. I'd also like to print cable stickers, but havent found time to update my sticker code in google. Most riggers, especially tour riggers, end up making floor marks. it would be nice to see some symbols for this. I made custom ones, but a lot of guys don't really know how to do that. It would be nice if some of the formulas and linkage in the data manager were accessible in vanilla data records. I use color to notate "worlds" for my hoist electrics. Like: "Red" distro powers "red" hoists which flies "red" truss. I use a visualization to show this, but it looks kind of bad, especially on hoists. I've been trying to just color the color parts of the hoist symbol based on their color tag rather than the entire hoist symbol. No luck so far. Changing the total chain length in the OIP for hoists really needs to be editable. This seems like an oversight? The hoist OIP really buries some of the stuff I'm trying to edit all the time. My custom data sheet has Hoist ID, hoist symbol, function, high hook weight equivalent, cable length and vendor all right at the top. I'd love to see my low-level beam calc operation work. I'm... not good at coding... so I've just made a symbol with a name and the coordinates called out in the data sheet, then I'll try to do the math within vectorworks sheets... Python seems pretty easy, I just have to learn "the first thing" about how it works vs. VWX and I can play around. I dislike how obtuse it is to make and use titleblocks in Vectorworks so I just made a fancy datatag that grabs some info and I fill in the rest with a simple double click. No need to dig into menus and wonder why there are so many blank fields. It would be nice to batch-edit certain things on sheet layres. I feel like this is something vectorworks probably has in some manager I havent found. Workflow here is: I have a show and I have 30 venues. Each venue needs a layout and an engineer submission. So I have a "VENUE" layer and class each venue I place in the design layres. Then I make a template for the layout and engineer submission, duplicate both 29 times and then start activating the appropriate class in each one, editing the titleblock (though I'm going to make that field smart when I get around to it) and double checking each. Then I batch publish. A function which I hold near and dear! The bridle tool has gotten pretty good. Bravo. I wish the mothergrid tool had the option to make the outsides or the inside dead hangs and vise-versa rather than all three being the same hoist symbol. Minor annoyance, but I mostly use it for deadhung spanners. I wish structural members had a data point to show the total vertical and horizontal weight (not tension) on them, as engineers often want to know. I do understand that this is something I can make a worksheet do with Braceworks/PA, but it really would be convenient. And if you read this far, you're a saint. I'm typing this as much for my own mind so I have a list... -

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@jcogdell Respectfully, I'd been wanting to talk to Vectorworks folks for a while about some of the growing pains within the rigging community in my market because it seems like the reality on the ground here is not being addressed. But for the sake of this conversation I'd just say that if I'm saying I need these low-level tools to bypass braceworks and half the riggers out there are bailing on the BRX tools in favor of the legacy hoists, then there's misunderstanding going on between user and developer. On a very basic level, production riggers here are almost all freelancers who learned how to calc loads by hand and then cemented that knowledge for years because Braceworks is laughably expensive for a new PR. Maybe in Europe riggers are company-people and that model makes sense? But everyone in my world is wondering what the VWX people are thinking with the pricing and features that seem like a minor convenience rather than a necessary tool. Having to constantly work around braceworks when you don't want the tool makes the business model adversarial, which is not what you want. Riggers talk. You want them talking about how cool their new tool is, not exchanging ways to work around it. Right now everyone seems very excited about Production-Assist... Basically a massive workaround with a license model that makes it affordable. There's no good reason Vectorworks couldn't make that money instead. As for liability, I have a lot to say on the subject of being deposed and what knowledge and papertrail is "good enough". "But I used braceworks" is not enough to educate the deposition even if it does prove a system. Mainly because liability is rarely a simple matter in a disaster. -

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@jcogdell On my cell. Plz forgive the typos... So, my issue using braceworks/production assistant for this is thatis have to build the show from scratch or have someone I trust do it. in the festival and tour world i get all sorts of drawings from all sorts of people and often at the 11th hour. I just struck a show testerday where the artist camp had changes the night before pre rig and the engineering plate already submitted was stamped (required) by the city. We normal just say "no" at that point but that camp owns the festival so... fun. The other anecdote is putting a tour in a venue where the engineer is super-lazy and tells you a couple days ahead that he needs you fo do his job for him and notate all the roof truss loads so he can stamp it and bill the show $5k. If I get either of those calls, there's no way I can take a strange drawing and make it brace works friendly in a quick manner. That's why I need something low-level. Throw in my beams, capture D and Span and spit out a number. I could nail a 500 point show in an hour rather than tinkering with braceworks for days. -

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@spettitt This is a fantastic bit of hand-holding. I really appreciate it. I'll chew on this for a good while. -

Distance between two symbols within the data manager?

AStein replied to AStein's topic in Entertainment

@spettitt Gotcha, so I'll want to build a script that does the following: Loop --> Each beam gets a UUID Each Hoist snags it's coordinates based on the beam UUIDs Then I can dump those numbers into my worksheet or be really cool and do the math within the script. I'm a bit intimidated by scripting. I blunder through Javascript to make things happen under google docs so I'm not hopeless, but definitely new. -

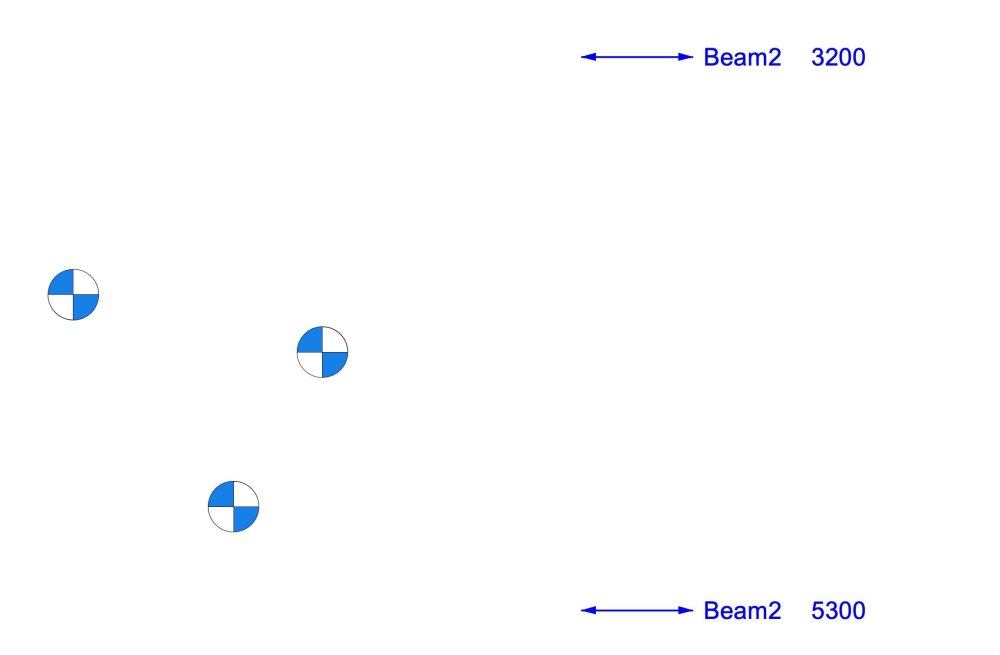

I'm not really into scripting yet, but if I need to be, this might be a decent project to start? So, I've had several venues lately who are requiring an engineering submission with ll vertical loads notated on their main beams as opposed to doing that work themselves... Ugh. I have a relatively obtuse way of doing this where I manually enter the distance of a hoist to a beam and the distance from beam to beam, then I throw it into a spreadsheet I made to do the math. It's clunky, but ti works. It would save me a ton of time on larger shows if I could make each hoist understand which beams it's between and how far it is from one of them.

-

That did it, thank you Scott. I was trying to attach a record over in the data pallet, but it looks like every hoist object has this record already attached, so no wonder it did nothing when I was attaching random others. Your walkthrough above got me there. I'm having trouble understanding how some data records can be referenced by symbols and "live" inside those symbols while others just seem to ride on the symbols, but not be able to talk to them... Maybe that's for future me... While I have you... I'm wondering if there's some kind of way to attach data tags to hoist symbols by default? Not a huge deal because the option to tag all eligible objects is powerful, but it would be nice if I could set a few tags ahead of time. Thanks for your time.

-

I have, but there were a ton of those data records in my resources. I tried 5 of them (in mm of course) to no avail. Maybe I need to attach all of them, see which one works and tag it somehow? I wonder if a data tag will talk to the object as a workaround? I could give that a try... But wow these are broken...