-

Posts

445 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Wesley Burrows

-

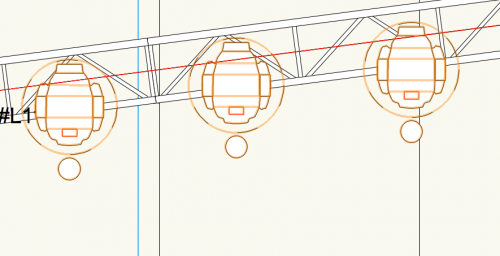

Spotlight - Align Distribute Tool Crashes 2018 SP1 & SP2

Wesley Burrows replied to Wesley Burrows's question in Known Issues

FWIW This has been filed as VB-146635. @JimW, I don't know if this thread should be moved to known issues or if it should hang here.- 10 replies

-

- spotlight

- align and distribute items

-

(and 2 more)

Tagged with:

-

I totally agree on this. I also get erratic results with option + dragging, and the mirror tool, which kills me cause I use it all it time. If I mirror something, say 4 fixtures across the center line on the same hanging position, usually one of the mirrors attaches its load position to it's old location and the mirrored geometry has a z height of zero or something arbitrary, while in top/plan the geometry shows in the correct location (but wrong Z height and the load is either not attached or attached to the wrong former location)

-

I have not encountered this. As Rob said you can do this with truss (either the PIO or braceworks truss) converted to a hanging position. According to Moritz Staffel (the creator or Braceworks) in his presentation at Vectorworks Design Summit, the best practice is to use Geometry rather than a Symbol when creating positions for Braceworks as to avoid potential errors. The thing I've learned from others and general messing around, (and was a source of confusion for me) is that you can't "attach" an item to regular braceworks truss or the truss PIO. However, the weight is automatically calculated and it assumes an item is attached if it is within a certain user-definable tolerance/distance to the truss. I believe this is the setting (circled) in the below image. The advantage of the hanging position and attach load is being able to show fixtures out of position for clarity while still calculating weight from their true truss location. This also allows the ability to move the position and have everything attached to it move with it. (Though I believe there are a few bugs with this to be address in a forthcoming service pack) This has been my understanding and experience anyway. -W

-

VW 2017/2018 Cinema 4D Export Bug?

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Hi @Selin. I've been talking to Joseph Block, he said he was able to reproduce the error with my file and forwarded it to engineering. JIRA VSS-60589 -

Spotlight - Align Distribute Tool Crashes 2018 SP1 & SP2

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Yeah, I've played with them a little bit, But not for a while. There wasn't much in the way of documentation and I didn't have a bunch of time to experiment with them. I just submitted this as a bug.- 10 replies

-

- spotlight

- align and distribute items

-

(and 2 more)

Tagged with:

-

Spotlight - Align Distribute Tool Crashes 2018 SP1 & SP2

Wesley Burrows posted a question in Known Issues

When using the "Align and Distribute Items" tool from the Spotlight tool set, VW 2018 SP1 crashes everytime I use the tool with fixtures on a hanging position. The tool seems to work if the fixtures are just in some open space. These were the settings I used.- 10 replies

-

- spotlight

- align and distribute items

-

(and 2 more)

Tagged with:

-

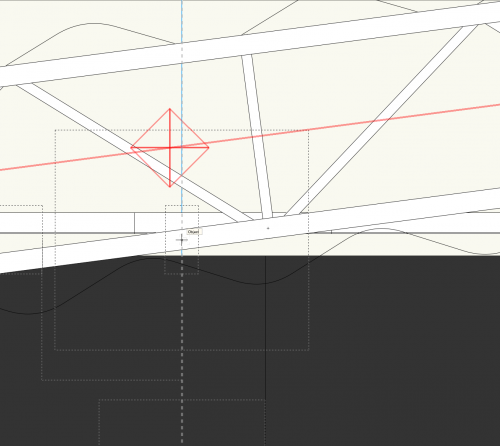

Hoist Insertion Tool Snapping is Offset

Wesley Burrows replied to Wesley Burrows's question in Troubleshooting

This really doesn't seem like the correct behavior. Support told me they believe it's operating as intended but I feel like it's incorrect. In CAD software I should be able to place the hoist with 100% precision to the beam while maintaining the center snap not have the tool dictate to me where the beam is. Anyone else?- 2 replies

-

- braceworks

- spotlight

-

(and 2 more)

Tagged with:

-

Works on Mac OS 10.13.1 and Chrome Version 61.0.3163.100 (Official Build) (64-bit)

-

I too confirm these observations. This just started happening with me on 2018 SP1 also.

-

Spotlight/Braceworks - Video Screen/Projection Load Attachment

Wesley Burrows replied to Wesley Burrows's topic in Braceworks

Thank you@Yordan Kostadinovfor the detailed answers! -

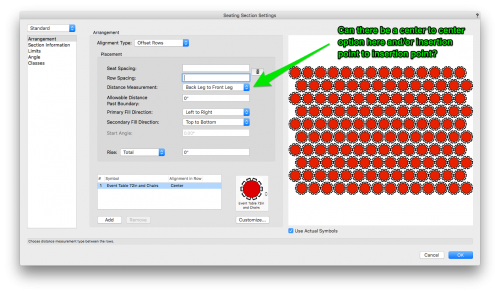

I'm curious, for those of us that have to deal with larger seating layouts regularly, how do you approach it? Do you start a ballroom or convention center layout with a giant rectangle and then start cutting in aisles for fire code etc? Build it a section at a time? For that matter which of the three different seating layout tools do you use? A few times a year I'm doing layouts that max out around 15,000 seats. This get's to be a special kind of bloated and difficult if you were to try and do as an enormous rectangle. How about bowl style seating layouts. Such as similar to the below image? Though this shows round horizontal aisles usually (in my situations) it's more of angled straight lines to form the "curve".

-

Spotlight/Braceworks - Video Screen/Projection Load Attachment

Wesley Burrows replied to Wesley Burrows's topic in Braceworks

So it does auto-associate with the truss pio without needing to be a hanging position? As in, it'll calculate the weight but not move with the truss if it the truss gets moved? I guess the thing I'm having a hard time with, is running system checks on objects and getting seemingly random load not attached errors. It's somewhat difficult to tell what is actually attached and what is not. There are even lights with the blue remove load arrow that flag with a label as load not attached. My company is purchasing Braceworks for me next week and in the meantime I've been trying to get some projects already in progress setup for it in advance. I'm currently just using the built-in Spotlight braceworks commands. -

Spotlight/Braceworks - Video Screen/Projection Load Attachment

Wesley Burrows replied to Wesley Burrows's topic in Braceworks

Is this braceworks truss? Or does this work with the truss PIO? Does it just auto associate with the nearest truss? -

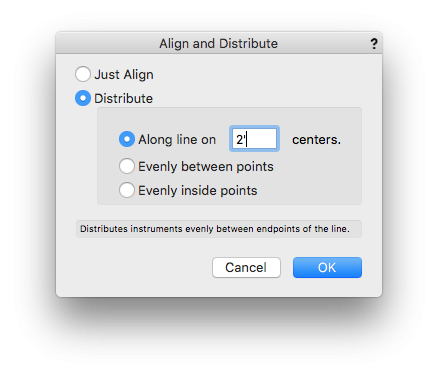

In the distance field there really should be an option to use center-center and/or insertion point-insertion point. For table layouts back leg to front leg and front leg to front leg are completely arbitrary.

- 1 reply

-

- spotlight

- create seating section

-

(and 1 more)

Tagged with:

-

Spotlight/Braceworks - Video Screen/Projection Load Attachment

Wesley Burrows replied to Wesley Burrows's topic in Braceworks

Good to hear! Thanks Mike! -

When you use the Video Screen PIO it shows two different weight fields, one for the screen and one for the PJ, which leads me to believe you should be able to attach the screen as a load on one truss and the PJ as a load on another. In reality, I have haven't been able to get this to happen. It all assigns as one item (as far as I can tell) so I've added load items for now. Should they be attachable separately? Or is that something that is in the works?

-

VW 2017/2018 Cinema 4D Export Bug?

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Tech support has confirmed my export issues too, but so far, only in the example files I've sent. Working with engineering to figure out what's going on. I'll report back when I hear more. -

It would be great if the Soft Goods Tool Set could calculate the total weight value of the drape based on a standard of measurement for drape/fabric. For example Rose Brand shows their weights as lbs or oz per linear yard (US) obviously it should also work similarly with meters. It would be wonderful if the tool could take information such as that and convert it to the proper total weight/lbs per foot. Based on the total square footage of drape. Currently I have to take the ((L X W) / 13.5) x lbs per linear yard to obtain the total weight and update the field anytime a drape adjustment get's made. EDITED TO ADD: The 13.5 comes from dividing the width (in inches) of the spec Rose Brand fabric (54"). So (54 / 12) * 3 = sq feet per linear yard. If the spec fabric on which the weight is based is a different size. Say 60", it would be (60 /12) * 3 = 15. So 15 would replace 13.5 in the above equation.

-

- 1

-

-

- spotlight

- soft goods

-

(and 1 more)

Tagged with:

-

When trying to snap a motor via the red insertion guides to a beam in a drawing (see the vertical light blue line in the photo) even when my cursor snaps to the light blue beam (as pictured) the red insertion square does not line up with the beam, it's offset slightly to the left. So the hoist always inserts slightly off the beam. Is this a bug?

- 2 replies

-

- braceworks

- spotlight

-

(and 2 more)

Tagged with:

-

Braceworks: Right click menu item "Attach Load"

Wesley Burrows replied to SCParker's topic in Braceworks

This +1000. I've had to manually right click / attach loads for almost every device on my hanging positions. They don't want to auto-attach no matter what. Even lighting devices, they work about 1/2 the time.