-

Posts

442 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Wesley Burrows

-

Mac Pro - 12 Core, 64GB of RAM, Dual D700 Fire Pro Ghx

Wesley Burrows replied to Andrew Davies's topic in General Discussion

I use that same machine, but with a 27" thunderbolt display. Only 2K but I still love it. I tried a 55" 4K TV for a while, that was pretty comical. I couldn't get far enough away from it :-) -

Braceworks - Drape vs Border (or soft goods teaser)

Wesley Burrows replied to Projx_CA's topic in Braceworks

I too am getting very mixed results with this using the Truss PIO converted to a Hanging Position. Curtain is really the only one that works right, border sorta works but it inserts with it's bottom Z @ the bottom Z of the truss so the border goes UP 19' taller than the bottom of the 12x12 it's hanging from. When I adjust the Softgoods PIO to correct this the calculation no longer see it as connected. I typically just use the Insert Load (distributed) tool for stuff like this because of the strange results I've encountered. -

Do you use a custom hoist symbol for these points or just use one that you typically don't have in the rest of the rig?

-

Hoist Label Background Not Working

Wesley Burrows replied to Steven Morgan's question in Troubleshooting

I had this problem with 2018, I had to delete my user preferences folder to fix it. -

Added my vote. I agree with all of the above points. I've had to resort to Cinema 4D with Hantmade's Stage plugin to get nice looking volumetric lighting renders. (And easy fixture fanning/focusing etc.) But I wish VW could do this internally. It kinda blew my mind that it didn't when I first starting using it.

- 54 replies

-

- volumetric

- rendering

-

(and 2 more)

Tagged with:

-

Does anyone here have any links to good reading information this subject? I'm always trying to find ways to better what I'm doing. But for those of us that (which I assume is most) have to submit, Seating Layouts/Revisions to the Venue, Venue Deck Plans to the Venue, Lighting Plots, to the Shop. Scenic Plans to scenic, etc. Do you maintain different revisions/issues etc for each specific trade? Just use a master revision # that you update when changes occur and re-issue the entire production package (what I do more or less, currently), or just publish the specific sheets relevant to the trade/recipient? I appreciate any insight. -W

-

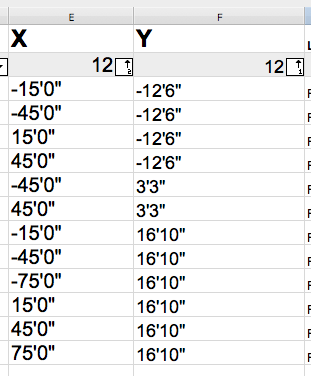

I'm almost certain this is a stupid question but for the life of me I can't figure out why when sorting ascending negative values (X on a motor X,Y sheet). Why I get this: Logic would dictate that -45 is less than -15. it seems like it should sort as, -45, -15, 15, 45. What am I missing? (This was generated with Spotlight > Reports > Create Hoist Worksheet.

-

Does anyone else find the service select portal significantly slower than the rest of VW's site/forums? I average around 7.6 seconds between clicking a link on there and and having the page delivered. I'm on a hardwired 1gbps ethernet connected to a 1gbps Google Fiber connection to the internet. (this is at my home office so I'm not sharing my connection with an office full of people) so I'm pretty sure it's not my internet :-) . The forums and main site are super responsive though. Just curious.

-

It's part of service select. Yes, you can continue working while cloud rendering is occuring.

-

2018 SP2 CRASHES DURING DWG EXPORT

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Thank you for the info! -

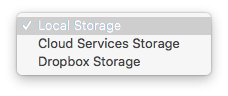

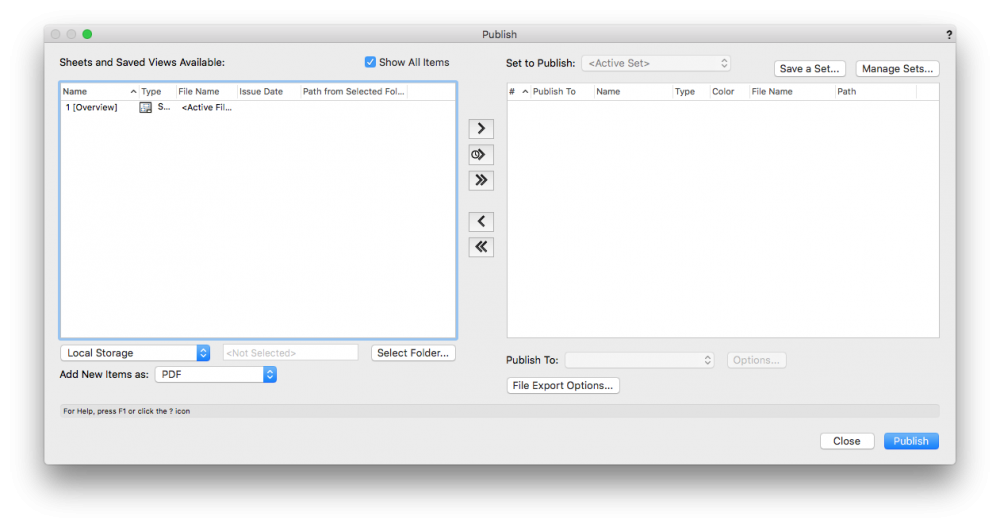

My experience has been: Yes they have to be in your cloud services folder, or allegedly dropbox if you have it linked to cloud services, but I haven't had much success with the dropbox link. You'll also need to upload any fonts to vectorworks cloud that are special. For now I've just added aliases from the dropbox folder I want to my cloud services folder, and that works. Publish is the same, you just have to change your storage dropdown to one of the cloud folders: (and your output file needs to be saved to a cloud storage location)

-

2018 SP2 CRASHES DURING DWG EXPORT

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Also here's the original DWG. pp_04.dwg -

2018 SP2 CRASHES DURING DWG EXPORT

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Attached is a fresh DWG (just received this morning) imported into a blank drawing. Crashes everytime I try to export a DWG. Venue_1.vwx -

Does anyone have any good camera symbol resources? On sticks, on skates, Jib. etc? I've typically gone to 3D warehouse and made my own 2D geometry on top of the 3D, but thought I'd see if anyone already had some nice ones they'd be willing to share :-) -W

-

Has anyone else run into this? Happens everytime. Isn't file specific (happens across different ones) and if I save the VW file as VW2017 and export with 2017 it works just fine.

-

Stupid question, but have you restarted VW? I've had viewports that render all black after 6 or 7 successful renders. In 2017 it happend all the time. I can't speak for 2018 as much as I usually render with Cinema 4D now.

-

Asymmetric Symbol Scaling Issues

Wesley Burrows replied to Andy Broomell's question in Troubleshooting

I've run into this scaling chair symbols asymmetricaly. The 3D geometry has a tendency to completely fall apart using something like Chair 4 in the library as a base. -

This is great! Thank you!

-

Does anyone have a 3D drawing of these? I reached out to my contact @ Atomic Design on Friday but haven't heard back yet. Sidebar. It would be rad if the Atomic stuff was included in our libraries :-)

-

Vectorscript - Save A Copy As

Wesley Burrows posted a question in Wishlist - Feature and Content Requests

I wish you could call this command via Vectorscript. -

Spotlight - Align Distribute Tool Crashes 2018 SP1 & SP2

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Bummer, according to Moritz Staffel @ Vectorworks Design Summit to avoid potential Braceworks calculation issues he recommends converting as geometry. So I guess it's one or the other.- 10 replies

-

- spotlight

- align and distribute items

-

(and 2 more)

Tagged with:

-

Thanks for sharing your workflows and experiences. I find it very insightful! From a code standpoint, (USA based) I too have often found the 14-16 seats (size dependent) to be max in a row to meet this IFC requirement: "Aisle accessway travel distance - The maximum length of travel along the aisle accessway shall not exceed 30 feet (9144mm) from any seat to the point where a person has a choice of two or more paths of egress travel to separate exits. (IFC 1017.4.3)" I rarely run in to any client/producer, etc, pushback on that from a theatre seating standpoint. I do however run in to pushback on seating for banquet rounds. Does anyone have any sources for code (I know it varies somewhat by municipalities) regarding rounds? I usually use this as a reference: https://www.lasvegasnevada.gov/cs/groups/public/documents/document/dhn0/mdax/~edisp/tst001962.pdf (I live in Kansas City, and we do events all over the US, but this seemed like a good starting point) For rounds, we are usually seating 72" rounds of ten, and that document shows ~6' table edge to edge if any seat is back to back, which is typical in a round configuration. So I usually start my round layouts @ 12' centers. Then people want to try 11', 10' etc, to squeeze more people in. I know that a lot of places will set this way, without saying a word, but if the fire-marshall gets a wild hair and wants to shut it down he could. Does anyone have any clear sources that either give me a leg to stand on @ 6' edge to edge, or somewhere that shows that 4' or 5' edge to edge is ok in certain circumstances? Or just general best practices that are a good starting place for code compliancy. -W

-

-

Spotlight - Audio Tool Set 2018 SP2 Can Crash VW

Wesley Burrows replied to Wesley Burrows's question in Known Issues

Tech support was able to replicate the issue and this has been submitted to engineering for a fix. I don't have a bug # though. @JimWI think this can move to known issues. I don't know if you can locate a bug # for it, for reference.