Joe-SA

Member-

Posts

232 -

Joined

-

Last visited

-

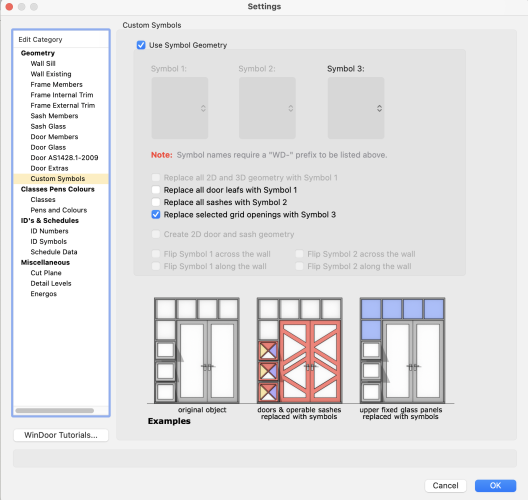

I'll add to this the WinDoor option of Custom Symbols. A 3D symbol of the panel can be inserted into the desired grid openings you choose. This works if the window sash or door panel settings can't make the exact configuration you are looking for. Joe

-

The forum thread above was started in 2019 pointing out how hidden line ignores the clip cube. The last note saying this feature is still not fixed was last year. I just tested in 2024 SP4 and it is still not fixed. We regularly generate interior perspectives with textures, lighting, shadows and overlay line work. We do this from an eye point location outside of the room in order to avoid the fish eye look and to be able to see more of the space. This is best done from a perspective section view. Hidden line and Shaded simply do not respect the clip cube the same way in Viewports. It is not consistent through the various other Rendering Modes, either. We've resorted to having to generate DLVP Section viewports and then set up a perspective view of that design layer model section. A massive file size and memory suck in order to do it. We've been jumping through this hoop for years. I've brought this to Vectorworks directly in the past with back and forth exchanges but still no action. This shouldn't be a new feature wishlist request. It is actually a bug that has needed fixing for the past 5 years. Once upon a time it worked as expected.

-

Picking up on this AFP vs SMB setting info....I ran into some issues with some employees setting up Project Sharing with AFP when in the past I've had much better luck with SMB for many years. I did a little research and found this article on Project Sharing.. https://blog.vectorworks.net/an-overview-of-project-sharing-in-vectorworks-software Which contains a link to this forum post from 2016 Which contains this NOTE: of AFP deprecation at the top and a recommendation to only use SMB following MacOS 10.13 which is High Sierra released in 2017. I also found this current Vectorworks University Course https://university.vectorworks.net/mod/scorm/player.php?scoid=40&cm=103¤torg=articulate_rise Here item 28 in the Frequently Asked Questions reiterates that you should use SMB only for any MacOS 10.13 or later. It includes a link to the same 2016 post above. VW2023 Is not supported by MacOS10.15 Catalina or earlier. VW2024 is not supported by MacOS11.0 Big Sur or earlier. All of this being the case....why are we still being offered the ability to choose AFP protocols when setting up Project Sharing Files? Should we at least be prompted that with any MacOS that has been released in the last 6 years it is recommended to use SMB Only and not AFP? Or Does the 2016 deprecation of AFP need better explaining because none of what I found today is evident to unfamiliar VW users as they setup Project Files. Some of us have been running AFP with VW2023 which has worked but generally it has not been a great experience. Meanwhile I use Project Sharing via SMB nearly daily with VW2023 and rarely have any issues but I will say we have seen some sync issues that have shown up intermittently with both protocols. It is still easy to find non-vectorworks sources for internet advice that suggest if you are running mac...AFP is the better choice. Can anybody clarify this? Seems to me the Project Sharing Setup could use some re-vamping to provide better guidance. I'm curious what's in the works for VW2025. For more context we are Dropbox for Business users with Project Files in a shared dropbox folder and Working Files stored locally. Most of us are running MacOS Ventura. Some may be still on Monterey. Nobody is running Sonoma as far as I know. I have not yet loaded VW2024 but I can only assume that nothing has changed in the Project Sharing Setup Dialog box in the latest version.

-

CONCRETE FOOTING PLAN VIEW VS SECTION HATCH

Joe-SA replied to Christian Fekete's topic in Architecture

I have found that when it comes to walls the class overrides will work on the class the 'wall object' is in but not on the components inside of the wall. We make our footings out of walls with dashed lines and solid fills. If you define this by the class the entire wall is in and you do not include any components inside of that wall style you should be able to override both line type and the fill when in section. It is the lines and fills defined by the components that I can't override. Additionally, I use custom line types with my framing members and then class override those lines back to solid in my section cuts as well. There seems to be some issues getting the textures correct in 3D when applying by Object instead of Component. This could be a bug or I just don't have a setting correct yet. I am able to set the proper texture wall by wall its just getting Wall-Footing class texture to show without the use of a component seems to be a bit tricky for some reason. -

I often put multiple WinDoor object together in a single assembly inside of a symbol when a single plug-in can't make what I need. A common one would be a double door flanked by single fixed doors. The '2' door setting makes the sidelights double door units, too. I'll make the entire perimeter out of one Windoor object leaving the sidelights as openings and then place a second and third plug-in into that assembly to make the final product. There are lots of different configurations where something like this is necessary.

-

Show Section Marker in Elevations Viewports?

Joe-SA replied to Scott Schwartz, AIA's topic in Architecture

I don't follow the forum that closely these days so forgive me for jumping in months later... I did not see it mentioned so I'll give you our solution for those who might not know of this feature. You can manually draw a section mark in annotations. This functions as a 2d mark that you manually locate, however, you can optionally auto-number it by linking it directly to an existing viewport that was created with the Section Line tool in plan. Not as good as automatically having it come in on its own but better than an un-linked mark that doesn't update when detail and sheet numbers are modified during development. For what its worth. -

VW 23 Project Sharing via DropBox Business constant failure

Joe-SA replied to Talal's question in Troubleshooting

For those interested in the solution to this problem....a simple log-out of our Dropbox account and logging back in forced a re-indexing of the entire local dropbox folder. Each account associated with the Dropbox for Business account need to do this. This latest Dropbox updated was prompted by a change Apple implemented with Monterey 12.3 which changes how the OS interacts with Dropbox and other cloud storage. Dropbox claims that they send prompts to indicate when their update will be running on individual accounts but nobody in my office was aware that this update ran in the background while they were working. It just appeared one day. Apparently it will take months for the update to roll out to every Dropbox account. Once updated all users will need to re-index the library. Hard to know when to do that with no obvious prompt or instruction to do so. -

VW 23 Project Sharing via DropBox Business constant failure

Joe-SA replied to Talal's question in Troubleshooting

In our early tests this problem may be specific only to VW2023 and not our previous version. As an office we skipped VW2021 & VW2022. We have been making a push to move people to VW2023 in recent weeks which is why this project was taken into VW2023 after being started in VW2020. We exported our file back to VW2020 and reset Project Sharing. All appears to be working fine. My .vwxp file is now syncing fine between myself and my co-worker without the loss of the 'offline' status as before. Some combination of software versions that includes VW2023 but not VW2020 is the issue. Backing out of VW2023 was the only solution I had left. -

VW 23 Project Sharing via DropBox Business constant failure

Joe-SA replied to Talal's question in Troubleshooting

Thanks Pat, You sent me down quite the rabbit hole. It appears this Dropbox Upgrade rolled out to us on Friday (March 24th) but instead of fixing issues it may have actually caused the behavior I'm getting with Project Sharing. After conversations with our IT Consultants, OS Upgrades not helping and a long online chat with Dropbox Tech Support I'm awaiting to hear back from them as they move the issue up the tech ladder. I have people in my office running everything from Catalina to Ventura and interacting with Dropbox without any issues. This appears to be a problem that is only happening with Project Sharing and it is only happening on one of the two stations we are interfacing from while syncing .vwxp files. Below are some links if others are interested in following this issue. https://help.dropbox.com/installs/macos-support-for-expected-changes https://www.macrumors.com/2023/01/17/dropbox-full-support-for-macos-12-5-by-april/#:~:text=Dropbox today announced that it,the update by May 2023. https://support.macincloud.com/support/solutions/articles/8000066740-dropbox-v170-4-5895-now-supported-on-macincloud-managed-servers -

VW 23 Project Sharing via DropBox Business constant failure

Joe-SA replied to Talal's question in Troubleshooting

Picking up on this thread....we are having the same problems running Project Sharing on Dropbox for Business with VW2023 SP4. I'm on macOS Monterey while my co-worker is on Ventura. Both iMac27s. We are long time Project Sharing over Dropbox Users. Worked through all the logistics to make this reliable and predictable long ago and have been using it well for years. Working files are local. We try to only check out objects by Layer and not one at a time just to keep the Dropbox queue as limited as possible. We are on our first VW2023 Project Sharing project. We were Project Sharing these same files in a previous VW version early last week without error. This problem showed up as soon as we brought them into VW2023. We are in 'legacy' mode since these files are not native to VW2023 if that even matters. When my co-worker does his Save and Commit I watch my local .vwxp file set to 'make available offline' literally switch to 'online only' completely on its own. The green dot turns to a grey cloud on my local drive just from the act of my co-worker updating the Project file from his station. It reverts trying sync to my local file drive. I watch it happen from my station. My working file then loses connection to the local dropbox .vwxp file until I change the local file back to 'offline' again and refresh the working file. This is not sustainable as inevitably the wires get crossed and we loose data from one user or the other. VW will ask me to 'Reset' the .vwxp file because my local dropbox file no longer matches the cloud version. But of course, it appears to be intermittent. The same reverting behavior doesn't happen to my co-workers .vwxp when I update. Last Friday I was seeing this behavior consistently with every test as described above while today my co-worker did many syncs without my file converting to online only at all. As soon as I stopped paying attention the problem returned and now we are scrambling to find the lost objects. I was hoping this was specific to SP4 but found this thread which appears to make it a VW2023 issue. May need to drop down out of VW2023 if we can't find a solution quickly. -

Tobias Kern started following Joe-SA

-

Vectorworks 2023 - major regression in section rendering…

Joe-SA replied to GatRed's question in Troubleshooting

I'm going from deep memory here but wasn't there a situation a few versions ago where EAP's with 2d base geometry in the profile vs Nurbs would give different results in sections vp's? I remember having to return to the problem EAPs and converting all profile objects to Nurbs to resolve how they appeared in section. It's a vague memory and I haven't seen it in some time now. -

I've had a busy schedule and often go months without jumping into the forum. It's only been recent weeks as I'm turning some attention back to upgrades and standards that I'm getting into it. I don't think you are wrong. For interior and exterior colors you can separate the trim finishes but not the frames, sashes, or doors. That is one big advantage the VW tools have. I believe you are correct on your other issues, too. When Julian was hired by Nemetschek I anticipated new VW Door and Window tools that were the best of both worlds. I have to assume that is still coming.

-

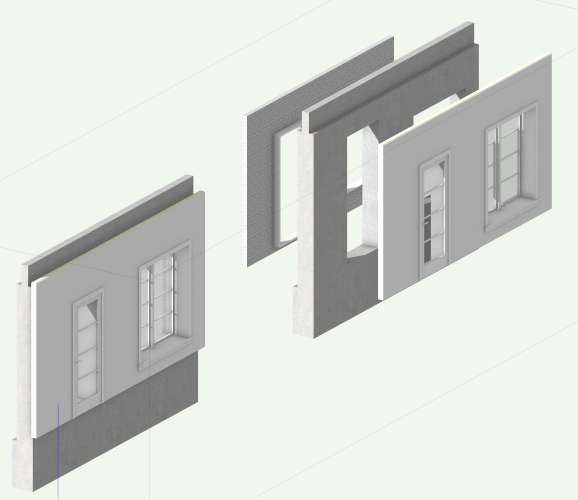

Well, these are not the only tricks up our sleeves with WinDoor. We have certainly run into a number of challenges getting what we want out of it and the solutions are not always evident but we've mostly managed to get there one way or another. For about 10 or 12 years now I take every upgrade and look at the improvements to each tool and I'll admit its been a close call in recent years but I've always come down on the side of WinDoor. For a long while I feared WinDoor would just up and go away and I'd be forced to switch. One of those tests is always a triple unit with a single arch with sashes shaped to the arch. My current understanding is neither tool can make that. We use the VW tools for Overhead Doors and mix them in at other times as needed but that is a rarity. Here is one example of a challenging situation I use in training new employees. We have a foundation wall with the need for inset framing ledges on both sides plus a brick ledge. (BTW-this is made with a single four component wall object) For the purpose of having a clean foundation plan the face brick wall and interior furring walls are always separate from the concrete. In this case, that meant every opening was a collection of 3 WinDoor objects in order to achieve the end results...one to cut each of the three walls. This was needed so that they worked everywhere we needed them to work....interior, exterior, section, floor plan, foundation plan, etc. We are almost entirely residential so we may not face all the problems others run into and certainly in VW there is always many ways to to skin the cat.

-

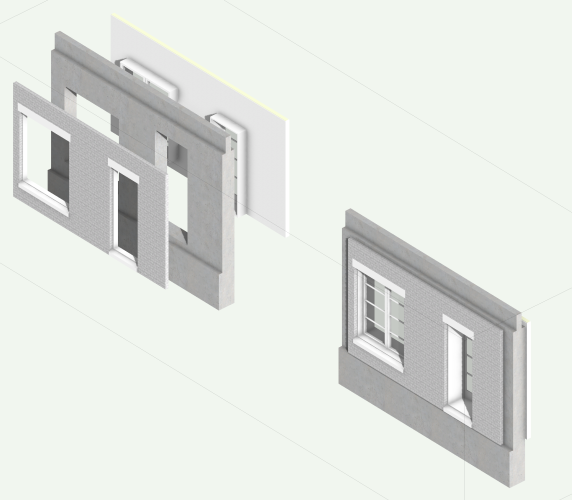

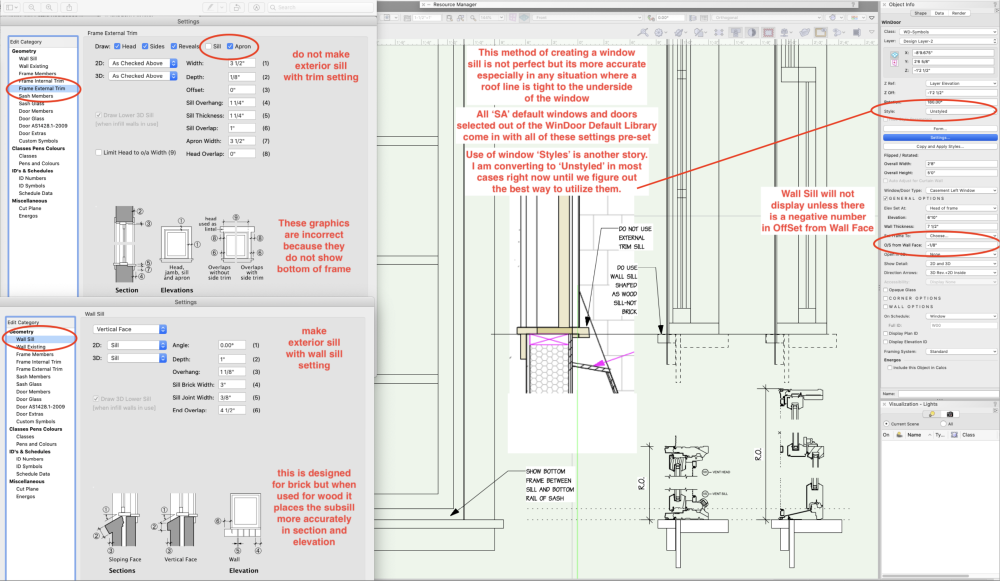

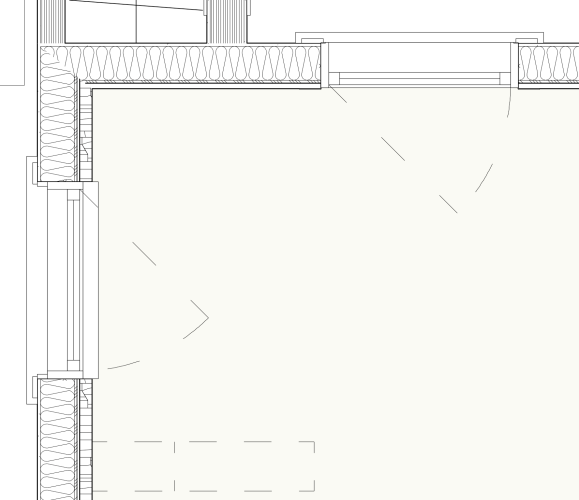

As a 20+ year user of WinDoor I thought I would add some thoughts on the use of WinDoor Sills and try to clear up some of the confusion inherent to them. We are able to get just about everything we want out of WinDoor but not without developing some tricks along the way that are not self evident. I have not spent much time with them in VW2022, however, but I don't think they have dramatically changed. First, there are 4 different objects called 'SILL'. The 'Frame Member-Sill' and the 'Internal Trim Sill' and the 'External Trim Sill'. Each of these show up in section in about the same elevation. We always had issues with the External Trim Sill's inability to drop down below the 'Frame Member-Sill' into a traditional sub-sill location. A number of years ago we started to use the fourth sill, the 'Wall-Sill' to create our wood sub-sills where we wanted them to show. The 'Wall-Sill' is designed for brick or limestone sills and we use it for those, too, but with the tweak of a few settings they work great for wood trim sills as well. This graphic is pre-2022 but I think the only thing missing is the component wrapping features. I created this to help illustrate to new employees how to get the proper sills in our models using Wall-Sills. The only real 'trick' for doing this in standard frame walls is that the Wall-Sill only shows up if it the window or door is offset from the face of wall with a negative number. We just drop -1/8" here to turn the Wall Sills on. The graphic below shows how the block nature of all these components are intended to align with true unit sections setting us up properly both in elevation and section. Mostly we are able to use the 2D settings within the WinDoor Settings to get what we want in plan with only a few minor compromises. A trick we do with the trim and aprons is to set the depth to 1/4". The trim object in the PIO has to sit on the face of the siding and cannot overlap it the way it would be built in the real world. We get a more realistic relationship between the face of siding and the face of trim. In section, we can simply overlay a 2D trim profile to finish it out. In the second graphic we just didn't take the time to go the extra distance to model the board and batten as it wasn't necessary for the completion of the CD's but it illustrates a wood frame window and a brick veneer with limestone sill window next to each other. WinDoor Tool - Wall Sill not Trim Sills (1).pdf

-

How to align wall's surface hatch while generating exterior elevation

Joe-SA replied to Rishie's topic in Architecture

At the bottom of the Render tab of the OIP of every Wall object there is a toggle called 'Use World Z for Origin'. Turn this on for all your walls. If you need a unique alignment you should be able to use the Attribute Mapping Tool.

.thumb.jpeg.48a6fdc44e48c98b8e1b507e86e57e95.jpeg)