Kevin C

Member-

Posts

158 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by Kevin C

-

I am an administrator (on the Mac). I presume that you are running PC which gives you the option of running each program as an administrator - Mac does not. As far as everything else in VW2017 working well, we are having quite a few problems. Major issues with Graphics - 2 machines are on iMac 5K retina with 4GB cards. Haven't loaded up on the older iMac yet (it is a 2011 i7 with a 2GB card. Text not displaying properly - mirrored / upside down / back to front / at an angle until the file was re-opened and all the test selected and refreshed (callouts only for some reason) Tiles and hatches no showing in the correct orientation - In the design layer but properly in the sheet layer, I had one guy in the office this morning almost pull his SO FAR. I do like the resource manager though, but pity that none of the bigger issues have been looked at again - Stairs and handrails for example. Someone needs to look at this seriously as I am still unable to use handrails for any project. Haven't had a chance to try out the walls and roofs yet, but as there was nothing in the update blurb, I am not holding out any hope that basic improvements have been carried out. Vectorworks is not just a design tool, it is a production tool and the software has to move past the 'pretty picture' and provide for production information.

-

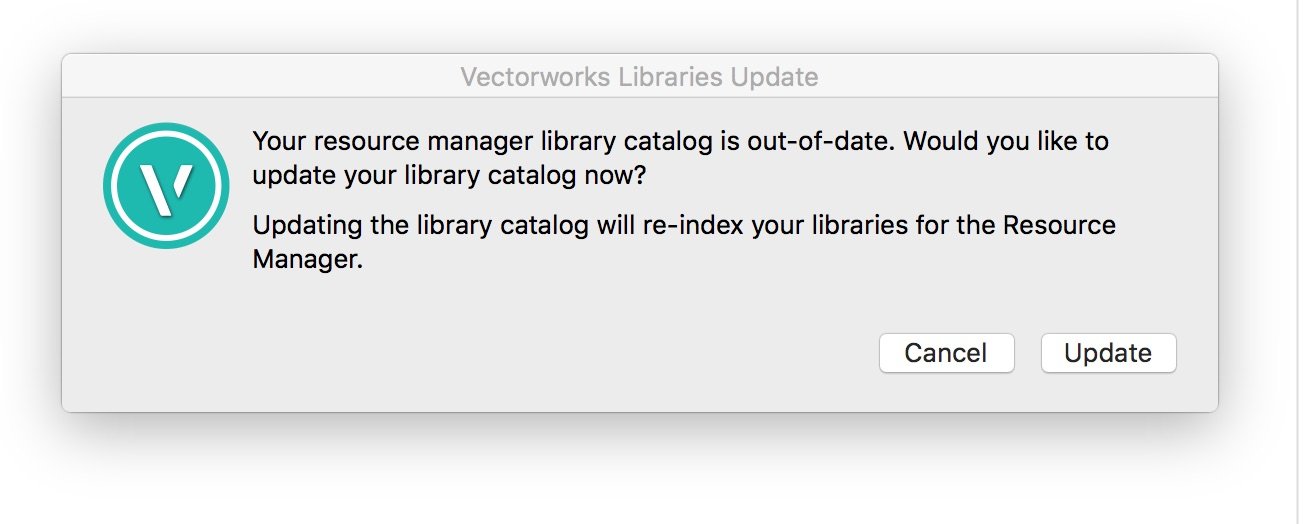

Does anyone know how to stop the pop-up for "Vectorworks Libraries Update" which pops up every time I start VW. I updated the libraries when it was installed and now every time I start VW - Getting a bit annoying.

-

I have been trying unsuccessfully to carry out a batch conversion of my 2016 files to 2017 but the batch conversion tool doesn't seem to work. anyone else had the same problem. I store all of my VW files in project folders on a NAS server and it worked perfectly well when converting from 2015 to 2016, but not this time. Thoughts anyone??

-

scheduled Unsupported Error when Importing rfa in VW 2017

Kevin C replied to rgcn's question in Known Issues

I have managed to download and sport a manufacturer's file (tried the Velux) and it seems to work - very disappointed with the result though imported as a wireframe model with no attributes (editable or otherwise) - less detail than an ifc import. I did however try and download the 2 sample rvt files (basic sample project and advanced sample project) from the Autodesk website and both failed to open - VW just hung. Question, Is there a file size restriction with revit import, as this could cause problems if I want to say to my Revit clients that I can now work with the whole team without having to force them to export to ifc (which does not go down well. Also - why is it only import and not import/export (ArchiCAD has both). Kevin. -

Hi Wes, Thanks for that. However, that only works when the individual component values are being entered into the system and does not allow for thermal bridging to be calculated (this would normally be carried out by other specialist energy software -which I have and am certified to use, for U-values, SAP Calculations and linear thermal modelling) Example: Modern timber frame wall, as per the specification in my post contains specialist membranes and low emissivity service voids and cavities to enhance the overall U-Value of the structure. The insulation and service void are both bridged by the timber studs. Details: Timber studs - 140mm thick infilled with 120mm PIR board (lambda 0.022) and and a 20mm thick low-e service void (declared R-value of 0.655) both of these components are bridged by the 38x140mm CLS timber studs at 600mm Centres. Convention states that 25% bridging is applied to the insulation and service void to account for the timber studs. - Entering the lambda value of each component only works if you can also add the bridging fraction (and the bridging element resistance). Breather membrane on the OSB facing the cavity (min. 50mm thick) - again a high performance reflective membrane with a declared R-Value of 0.655 (Protect TF200 thermo in this case) The external leaf in this case is an existing sandstone external wall, but could be anything as its just a rain screen The internal plasterboard (in this case) is double sheeted due to the fire resistance requirements of a flatted property. As you can see, although the software is smart, unless it has an approved U-value calculator built in (for each country that uses the software) I would not trust it to give an accurate value in terms of thermal efficiency. I need to be able to select a wall and know that the U-Value is correct or be able enter in an overall U-Value for the structure. If I need to convert it to an overall R-Value, so be it - its not difficult to do. In relation to the overall reported 'R-Values' for the generic wall constructions in the software - they are all US (imperial) R values, even when the project is being designed in metric, so are all wrong, or rather the software has not converted them to metric. Example, all of the timber frame walls have a pre-determined R-Value of 0.17, I calculated "nbl_Ext_Blk-Cavity-CBPBrd-TmbrFrmInsul-MtlFrm-GypPlstrbrd" and the R-Value is 5.184 which generated a U-Value of 0.20 I do have one question in relation to the default timber frame wall styles though (specifically the UK ones). Who on earth decided on the standard constructions. No-one uses particleboard in a timber frame - you won't get an agreement certificate for it! and no structural engineer will sign it off, because they are nothing like what is built as standard practice (or have ever been) - from my experience at least.

-

Trevor, I fully understand how to get from a U-Value to an R-Value, that is not the issue. The problem is that in Energos the R-values for equivalent constructions is of the magnitude of 0.17 (check the pre-populated values for some of the generic wall constructions), which would using the formula U = 1/R, give a U-value of 5.88 which is the same as a polythene sheet!! This is obviously wrong. I have done some more digging and found that in the US the R value unit is h.ft.ºF/Btu. How are we meant to use a system that cannot calculate values in metric. Also means that there must be a 'fiddle' in the software to export to PHPP - as that system is fully metric.

-

Can someone please help me with the data input requirements for Energos. More specifically what the R-Value is and how do I relate it to the U-Value of a construction. Example: I have a project where the wall makeup is 140mm timber kit using 120mm 0.022 rigid board (thermal conductivity in W/mK) reflective membranes and a standard Low-E service zone internally finished internally with 2 layers 12.mm plasterboard and externally there is an existing sandstone wall with a 70mm cavity. This gives a U-Value of 0.19 W/m2K (Watts per square metre per degree Kelvin), the equivalent R-Value for that construction is 5.304 m2K/W. This makes no sense whatsoever in the Energos calculations, as R-Values for the equivalent constructions in the database are similar to the U-value (but not the same). Is there a units or conversion problem? - Ie. The building is being constructed in metric (SI units) and does Energos work in imperial?? If so there is a serious problem wth the software engine. Or have I just got it completely skewed. I have attached the wall U-Value calculation for information Please help.

-

Kizza, That's the only way I could think of doing it as well. The situation is that my client's engineer uses PDS software to create the roads and drainage model and I am have to generate the site profiles for planning (comparing existing and proposed etc.) and for sales so that they can see the garden slopes. I can generate two independent site models, have them on two independent layers and then view generate the sections etc. Only thing is that I have to generate everything twice. The problem was in this case the engineer had only modelled the altered area so the existing survey model and the proposed model didn't marry up (as far as the extents were concerned. I had to trace round the proposed contour model, trim it from the existing survey model and then combine the two into a single drawing which would then match the extents of the survey. Thanks anyway. Kevin.

-

I have an engineer who has carried out the engineering on a housing layout for a small site. I now have two 3D autoCAD files. 1. The existing site survey and 2. The proposed site levels and contours I know how to generate two individual site models and work on them individually. The question is can I import the survey model as the existing terrain model and import the proposed site level drawing as the proposed site mode, merge them together, then add the houses etc. to the proposed. Kevin.

-

I have an engineer who has carried out the engineering on a housing layout for a small site. I now have two 3D autoCAD files. 1. The existing site survey and 2. The proposed site levels and contours I know how to generate two individual site models and work on them individually. The question is can I import the survey model as the existing terrain model and import the proposed site level drawing as the proposed site mode, merge them together, then add the houses etc. to the proposed. Kevin.

-

Carrie, Joining two separate files using the same technology as AutoCAD doesn't wok in VW. I.ei inserting a file as block then exploding it. The only way to combine files that I am aware of is to join the two files together by importing the layers and objects. Let me explain: 1. Create a new file (with blank template). 2. In the navigation palette, create a new layer, but instead of selecting "Create a new layer name" choose "Import Design Layers". 3. Using the "Choose" button navigate to the file you want to import from an select it. 4. The layers in the VW file will now appear in the dialogue box - Select the layer, but remember to also ensure that the "Import layer objects" check box is ticked. Repeat for the layers you want to import in all the files you want to import from. If there are layers of the same name - VW will add a suffix the the new year -1, -2 and so on. Doing it this way will bring in layer heights etc. Hope this helps. Kevin.

-

Fergus, Is this what you are looking for - Standard rebated windows and doors. The attached file is a screenshot of a 10mm facing brick blink over the kit - Client required all opening to be brickwork sizes. Unfortunately VW cannot show firestops or lintels for timber frame (which is a shame). The Cill detailing is getting better, but still a long way to go. It is actually quite straightforward - once you get round the quirks of VW. 1. Create your window and put it in the wall (Take a note of your jamb and wall width). This is typical apartment external wall (U-Value 0.19) Example: 372mm wall (2 x 12.5mm plasterboard / service void 140mm kit / 9.5mm OSB / 50mm cavity / 102.5mm Facing Brick) Window jamb = 65mm thick Will require an offset of 51mm to sit the window frame on the inner brick face (Standard detailing) 2. Adjust the window offset - It always has to be moved. Who wants to put a window in the middle of the cavity???? 2. In window settings - go to components and select 1 external component (no splay. This will now put a drag grip on the LH side of the window. To adjust the blink size, just select and drag. I usually select / drag then hit tab and enter the distance (10 / 15 / 20mm) as required. If you have a roughcast finish to the external leaf, select 2 external components (and so on). 3. The Internal is just the same as the external although you can also drag the internal finish horizontally and vertically (either by feel or by specified distance). Hope this helps. Kevin.

-

I've always had the same problem. I have just ended up creating a custom field in the worksheets. Anyone who has not come across this problem is obviously not exporting their models for take-off and scheduling. What is needed is the ability to create a custom gap at the head and base for "fitting" and a custom threshold / weather strip (if needed), or even better - allow for a carpet tolerance. We should be allowing at 15mm gap at the door base. Or even better having a tab in the door settings which allows there to be different shim gap for the jamb, cill and head. I presume that you are using a standard metric door. Internally (let's say a 826x2040 door). If the door frame is 35mm thick you would normally have a 2mm gap between door and frame and a 5mm fitting tolerance giving a structural opening width of 910mm. For the lintel height above FFL you would again have a 2mm gap at the head, 15mm gap at the floor - this gives a module height of 2092 leaving 18mm shim gap at the head between the frame and lintel. If you have to use one of those stupid imperial doors - you just end up with a bigger gap at the head. The problem only arises though when you are building with masonry internal walls - if you're using timber kit, you can just adjust the lintel height to suit (2064mm AFL, rings a bell for lintel height). Externally - you have to tie in with standard coursing and you end up with shim gaps which have to be filled either with timber packers or something else. The only way round this is by old fashioned large scale jamb / head and cill detailing

-

I would always import a dwg file into a blank VW file and then reference the new VW file into the project and a design layer viewport. Reasons for: 1. You can export the dwg reference file as a dwg file back to the originator easily 2. If you import a dwg file directly into VW it will overwrite your class settings (dwg file imports always have fill on as solid - causes havoc with drawings) 3. You can always overwrite the dwg settings in the advanced settings tab of a design layer viewport to display how you want it to 4.Your file will not get overloaded with autoCAD layers (classes) - they will only show up in the viewport, which you can then customise. Reasons against - None that I am aware of. One thing that would be good for VW importing and exporting dwg files is the ability to use the dwg originators ctb file from an e-transmittal (or one which we have created ourselves), then we would be able to replicate the file settings and stop the constant moaning from autoCAD users about linetypes and colours to being incorrect

-

Amelia, Once you have joined the walls, you have to join the components. VW isn't very smart in this respect and you have to tell it which components should be joined in on place and which components nee dot be joined in a corner. It will take a bit of practice, but when it works its great. Regards, Kevin.

-

Amelia, They are two separate roofs, so imho there will always be a junction between them - hence the line. I would think that the only way to hide the line is to draw a 3D polyline around the whole coplanar roof surface in the plane of the roof and either attach a roof finish to it (roof tiles?) or a simple shade. Also if you have Renderworks, you can attach a render to the face of the roof and Renderworks should merge the two together (I think). Regards, Kevin.

-

Limiting size of pdf export

Kevin C replied to Kevin C's question in Wishlist - Feature and Content Requests

Tim, Yes that's the whole process time. Kevin. -

I have recently started using the callouts and the database manager to generate standard office text and specification. The ability to have a central notes database which can be updated and used to update other drawings is brilliant, but I have found some (what I feel are) major shortcomings. 1. When trying to import notes from the database say for a Building Warrant submission, there are standard notes which must be included every time. Why is the only way that I can import the notes is in a form that is predetermined and completely inflexible Eg. A) The only way to import notes from the database is to import through callouts - Why??? A callout by default require a leader, and is usually a short text string. I want to have access to an office database which contains specification and notes and that can be used to generate a full project specification if required. B) Callouts are near impossible to format, other than the most basic of editing What would be great is if when selecting the callout from the basic tools and the dialogue box opens (either stand alone or importing from the database) - Could we have an Insert as callout or Insert as notes button and allow custom formatting to the notes (see below) 2. Often projects will have notes from different parts of the databases. Why can these not be inked so that when one note ends the next one begins directly afterwards (and copies the same formatting (Ie. width of text box / font and size etc.). Linking different 'callouts' would also allow for easier editing and mean that when the office database is updated, if a project requires to have its notes amended, the whole specification wouldn't have to be reformatted, which at the construction stage, could mean dozens or even hundreds of drawings 3. Start using columns so that notes can flow instead of having to create multiple viewports which have to be adjusted every time a note gets updated 4. Allow for importing from word processing programs (copy and paste - with formatting) or direct import from Word (Exporting to word would be nice to have as well)

-

'Types' or 'Saved Views' For Viewports

Kevin C replied to Tom Klaber's question in Wishlist - Feature and Content Requests

+1 for me. Could be used to standardise all drawings and make for a corporate style which would then be consistent. The option is there with the eyedropper tool to make various viewport properties match each other, but to have this as an office wide resource would be great. -

Is there any way that VW can be set to either produce a warning when exporting to pdf if the file size is going to be greater than a predefined level. For example (I think i've mentioned before in other posts) - Preparing submission packs for Planning Consent - no file can be greater than 5MB. Also when creating viewports in sheet layers, it would be great if the object info pallet could give an estimate of the proposed pdf file size of that sheet so that adjustments could be made to viewports (resolution up or down) before sometimes waiting an hour or two (or more) for the pdf file to be generated only to find that the file size is too large and you have to start all over again.

-

Jim, Following up from Tim's post (and your reply), BREEAM is not the UK Government approved tool for demonstrating compliance with the Building Regulations - The UK tool for domestic buildings is SAP and for non-domestic it is SBEM, neither of which are mentioned anywhere. BREEAM, although a very good tool will not tell you whether your design complies with the relevant regulations (neither does Passivhaus - for the UK anyway). Can you expand what you mean by the compliance presets? If ENERGOS is meant to give an idea how energy efficient a building is, it has to be against a benchmark that is recognised. For the UK that is SAP for domestic and SBEM for non-domestic. Interesting what you are saying about the xml files - Will the energy model be able to export the xml data in an approved format (my energy design program imports from an xml file). Kevin.

-

Results are in - didn't work. This was in the screenshot "Your file is already compressed incredibly well. Even our magic compression formula can't make it any smaller. Sorry."

-

Thanks Tim, Yes I have used preview - with varying levels of success (sometimes it doesn't seem to make any difference at all). I have uploaded a 9MB file for testing to smallpdf.com - still waiting for the result. Kevin.

-

Seve, I have a T520 printer which I have set up for wireless access and after an initial fallout with HP (and Mac) I found the solution to the page rotation problem. My printer is a 24" printer so it takes the 610mm wide roll (perfect for printing out A1's and A2's however the margins which you have to allow the printer to use for rotating the plot for and A2 are pretty useless so the solution is as follows: A1 sheet - prints as normal - Note the page size is 594 x 841 To set the computer up for A2 - Step 1 - In VW start a blank drawing (or an existing one - it doesn't matter) Step 2 - Go to Page setup then select printer setup and in the Page Attributes settings select the printer you're having the problem with and go to manage custom sizes. Step 3 - Create a custom page size at 594 x 420 (note the 594 goes first) and set the margins at 5mm all round the sheet and select OK. Step 4 - Store it as "A2 Sheet" or whatever takes your fancy - This will add it to the bottom of the sheet size options. The sheet is now stored permanently in your Mac preferences In VW Go to your page set up as normal For the A1 sheet - select Landscape For the custom A2 sheet - select portrait Obviously if your machine is an A0 plotter - you will be printing A0 sheets perfectly well, but struggling with A1 sheets - Using the same method as above but using 841 x 594 will create the rotated A1 sheet. I found that doing it this way allows me to import my title borders, set them as "fit to page" with 5mm margins all round. This is a Mac problem. The Windows printer driver has an autorotate functions which does t automatically. Hope this helps. Kevin

-

The pdf file size is a major problem. When creating a file set for Planning Consent or Building Warrants, the Local Authority has a 5MB maximum file size limit. This is across the board. It is not uncommon for me to have to drop pdf resolution down to the 36dpi mark to get files below 5MB, which as you can imagine completely reduces the quality of the output file. I should be able to produce an A1 pdf file at 300dpi that does not exceed 5MB. I have found out that tiles seem to be particularly poor when exporting to pdf. The fact that email providers now easily accept 10MB files is not the problem, I am dealing with government agencies who will not permit files larger than 5MB. Kevin.