-

Posts

2,048 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Everything posted by digitalcarbon

-

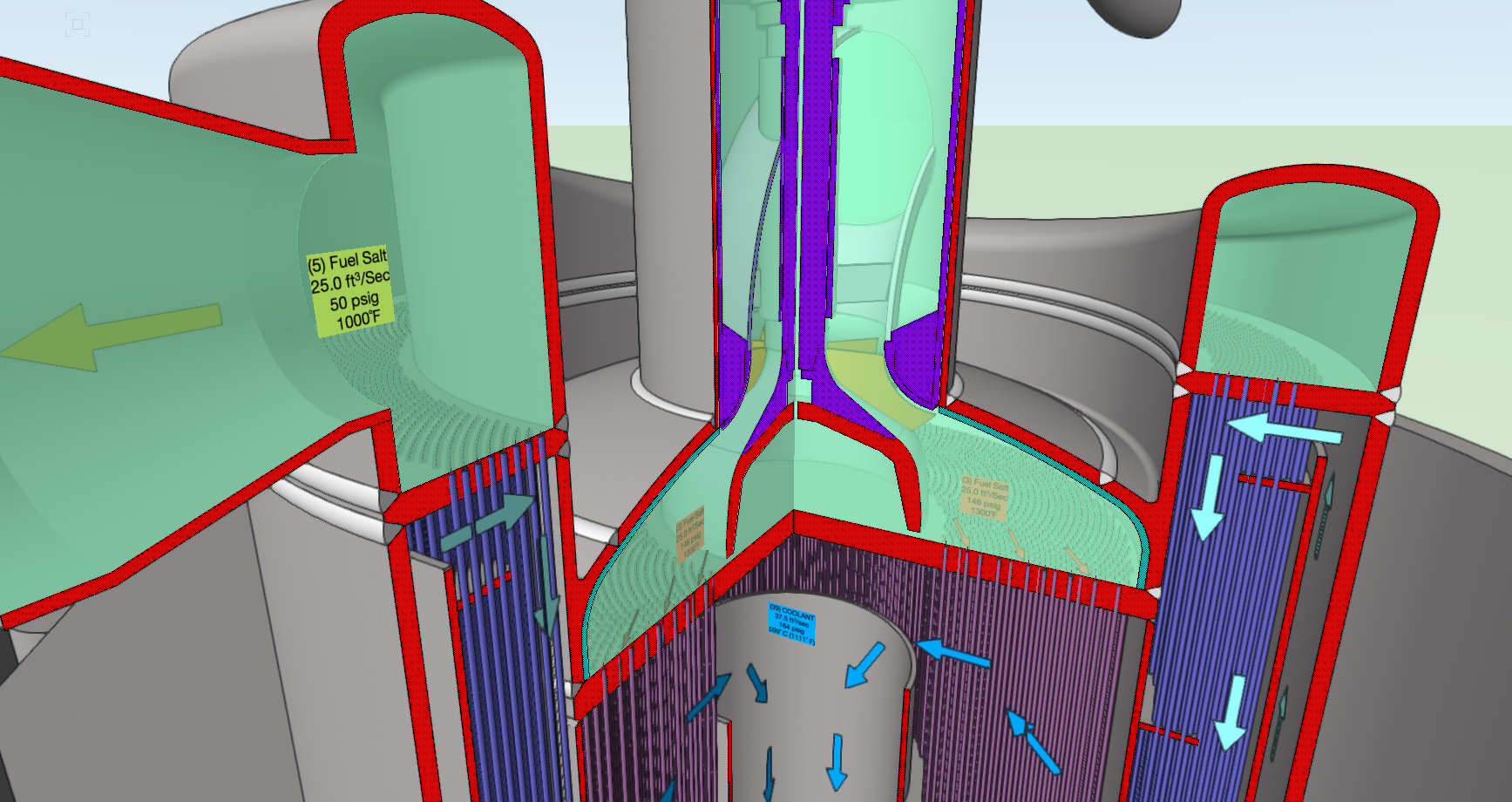

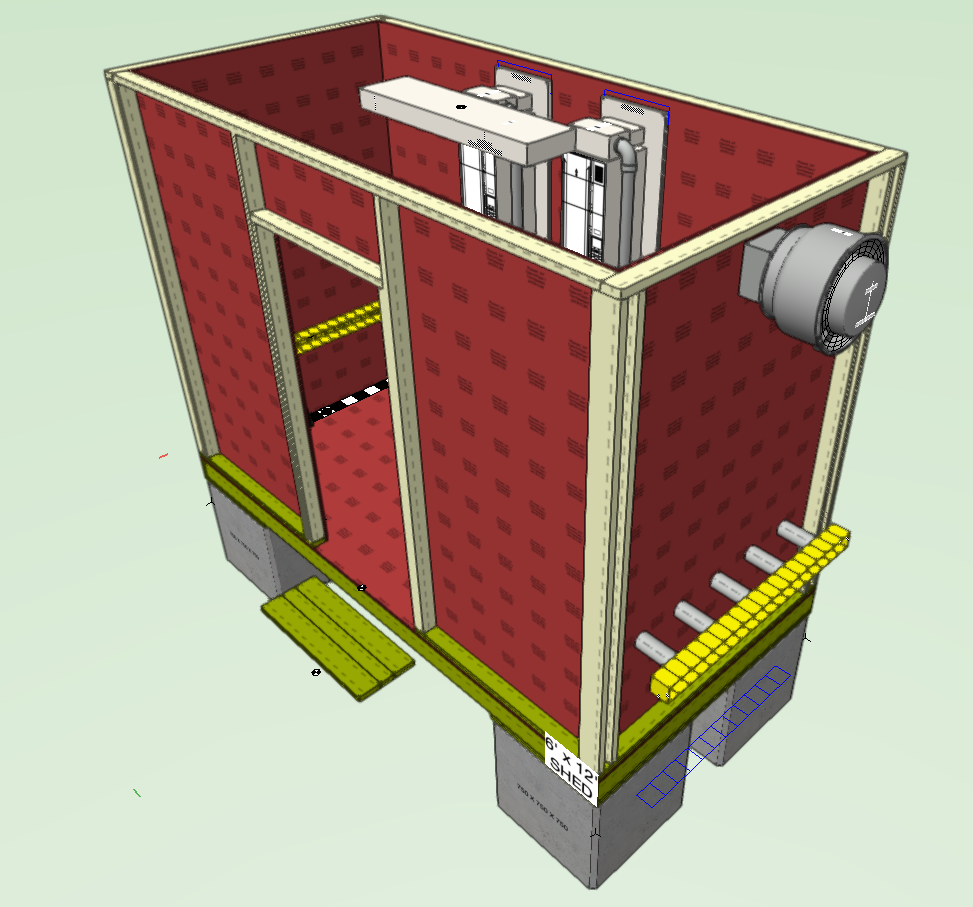

A sample of a sub-system...something like this will now be done in mechanical cad. Using VW for collecting and placing these systems on a site & working with civil for Northings & Eastings. The shortcomings of mechanical cad are they don't work with the ground plane concept nor should they. If someone developed a way to import mechanical cad models into a good 3d civil cad. Auto CAD civil 3d doesn't count its terrible VW VGM is the gold standard of what 3d should look like. (Onshape models import well) Then you could say good by to Revit, BIM360, Archicad, etc At this point I think I could do a bridge, sky scraper & definitely a house foundation, in mechanical cad.

-

So "sub-systems" are being compiled in Onshape along with the BOMs and then those assemblies are exported into VW for placement on the site or building.

-

23-39 29 11 Waste Water Drains.vwx

-

23-39 23 00 Electrical MH.vwx

-

23-37 00 00 Equipment Racks.vwx

-

23-37 00 00 110 Blocks.vwx

-

Moving all this type of stuff over to the mechanical dept (Onshape)... 23-27 69 00 Antivibration Mountings.vwx

-

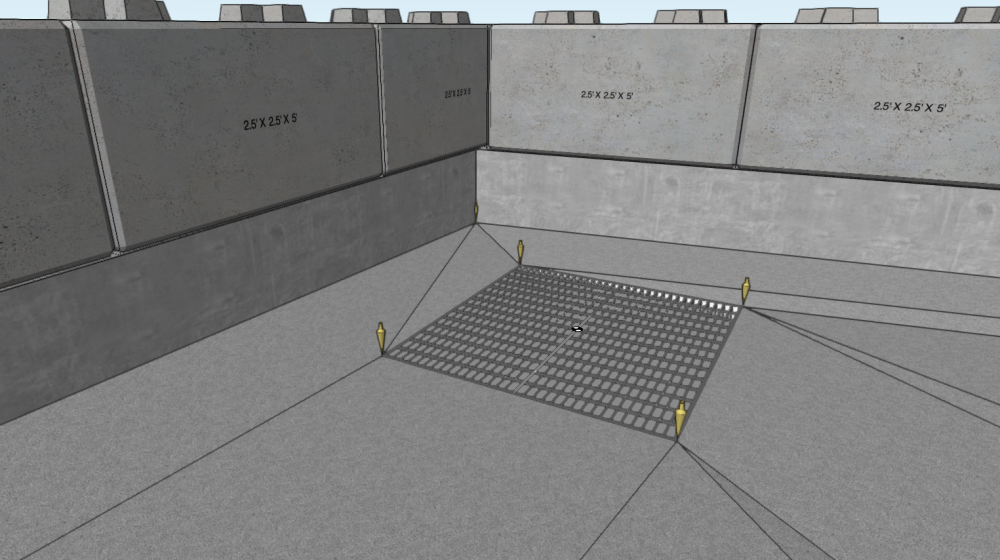

Let's say that we are all working on separate buildings for a large campus. There comes a point where we need to load all our models into something for the grand layout. If this grand layout place was a cloud based cad system then you all could still work in your specific cad but then just reference in your models. Foundations and first floors for starters. Like Referenced View Ports. These RefVPs would be then be moved into position according to the State Plane or UTM. Then the Civil people can then go around an work out all the surface items that are between the buildings (see image) So I guess the first AEC cloud cad system would be Civil first. DTM, Concrete, Foundations, Drainage etc.

-

-

Just sharing something with you.

digitalcarbon replied to RuiSantos___'s topic in General Discussion

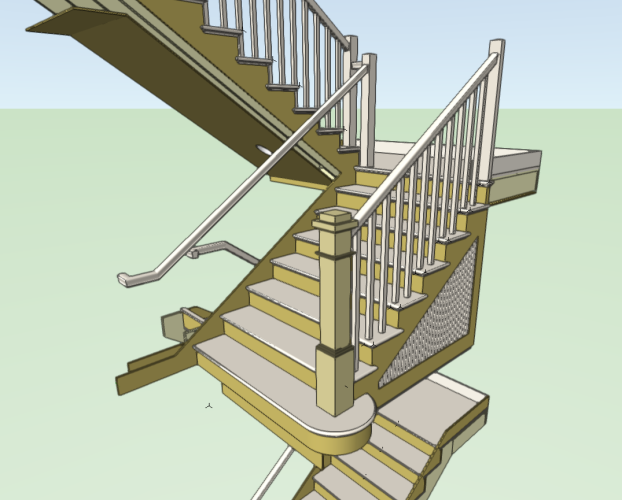

coming from a window washing/maintenance background...I aways ask myself "how am I going to wash those windows or fix that?" Sorry... -

there is no "upgrade anxiety" with Onshape. No hardware upgrade issues...any computer that can run a browser is ok. Still have not upgraded to vw 2022 yet. I just don't want to deal with it.

-

-

New Mac Studio M1 Max or M1 Ultra Thoughts

digitalcarbon replied to HEengineering's topic in General Discussion

-

New Mac Studio M1 Max or M1 Ultra Thoughts

digitalcarbon replied to HEengineering's topic in General Discussion

i think there is another thread on this topic by @Christiaan. I have similar questions. what i want to do is get back to my Mac mini way of working...which was to plan on upgrading ever 2 years to a new mac mini but not have to keep replacing my monitors (that is why i never did the iMac route) so with that 2 year approach i just needed to keep myself happy for 2 years...then get new.. this way i'm not stressing about upgradeability. it seems like this new computer will allow me to get back to my 2 year program. -

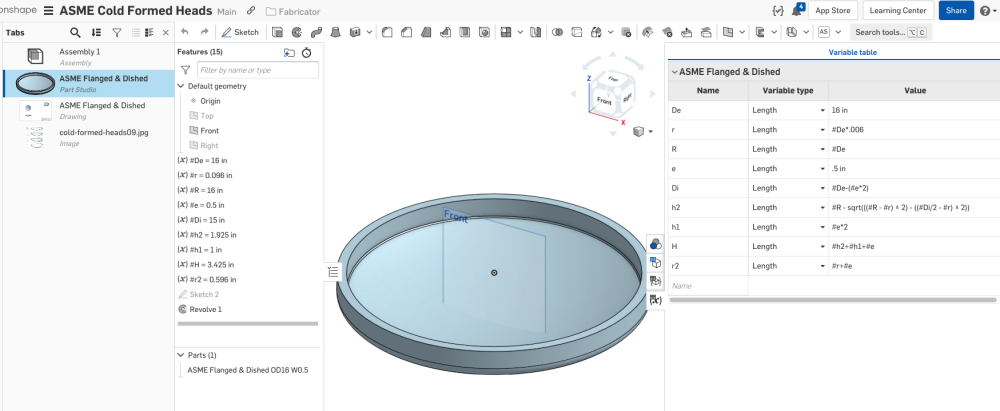

another example...all I have to do is change the OD and wall thickness and the rest of the dims update by formula. Mechanical CAD is another world...but I would not want to do any architecture with it.

-

Onshape has a free version so you could just use that...the only problem is that all your work is public. no one can mess with it but everyone can see it.

-

then i take all this piping and place in VW with the proper Northing and Easting then sync with the Civil people...who (currently) can not really deal with 3d product. but now I have site model w/ drawings (VW) and fabrication model w/ drawings (OnShape) its the best of both worlds.

-

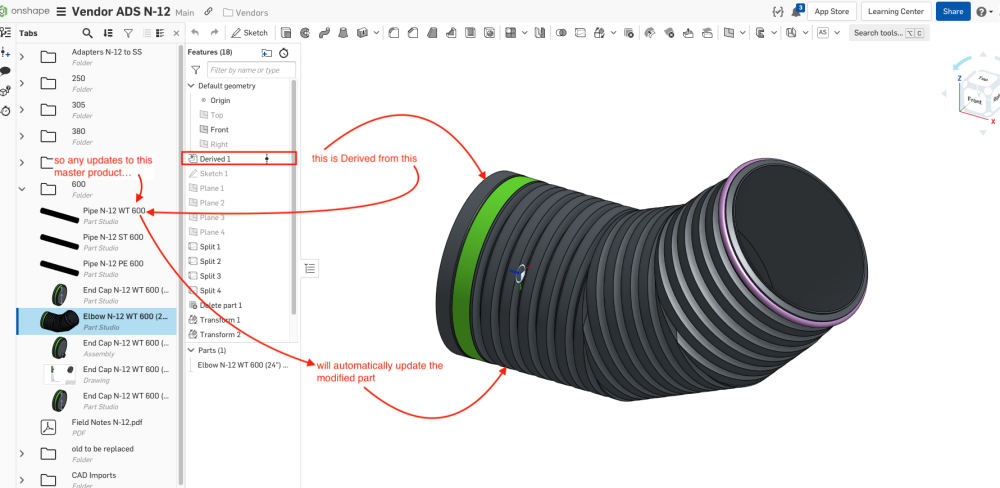

also you can make "product" object...then take the product and modify it for a particular project... this modified product is still "derived" from the master product so if the master product gets fine tuned, then this fine tuning gets pushed out into all the modified product in all your projects... In VW you have to copy a symbol and then modify....and if later you find out that you want to improve your master product then ok...but that will not update all the mods you made for all your project... Ex: you will note on the example below that the ribs have a "square" profile. this is actually round in real life (i do it to keep poly count down)...but lets say one day i wanted to make it round to be more like real life...all i have to do is change the one master product (Pipe N-12 WT 600) and then all the hundreds of parts that are derived get updated in every project... that is the other reason i do all my piping in mechanical cad

-

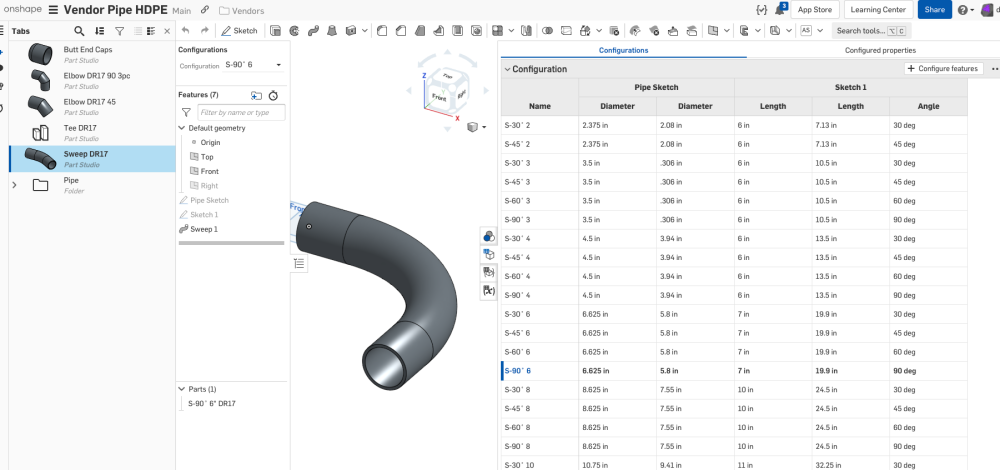

a mechanical cad system has a way of making one sketch geometry then attaching config dims so you can make the whole family of pipe from one model. In VW i would have to make a model for each variation...so lets say I did...but then the next day i found out that one of my dims was wrong...in VW I would need to open each symbol and fix but in mechanical cad you just retype the correct dim in the spread sheet shown. This is one of the reasons why I moved all my piping over to mechanical cad.

-

currently i model all my pipe & pipe runs in Onshape then i export parasolid to VW...in VW i have a 3d symbol for each pipe run....so when the piping gets updated then i just update the "guts" of the symbol and the symbols that are placed in the architectural model gets updated...this way I don't have to worry about repositioning the piping in the big model...

-

-

I think old paradigms would be discarded rather quickly.

-

the broken links problems exists in: Vectorworks Bluebeam Revu Solidworks Does it exist in: Revit? Archicad? others? can anyone comment?

-

creativity and organization...these are two sides of the same coin. when you get into a creative zone you do not want to be worrying about how things should be named or organized...so you spend 8hrs on a creative spree...at the end of the day you realize that organizationally things are a mess...so you spend a few hours doing clean up... Paper and pencil seems to be the best tools to do creative ideas but when you are done...what do you do with it? organizationally, collaboratively you cannot do much...hence the value of computers. Great for organization but bad with creativity... that is why you had Ivan Sutherland Sketchpad in 1963 3d was clunky until Sketch-Up came out in 2000 to understand the name of an object you have to understand its purpose...that may not reveal its self until the creative session is done...then when you are doing organizational clean up you start to understand relationships better and the name will change (provided you attempted to name at the start vs part 1 part 2 etc) Hence the need to have your links not break when weeks or months later when you continue to do clean up... here again we have a "critical mass" or "tyranny of numbers" thing developing. we are going to get to a point where we have so much things referenced that you will be spending all your time reestablishing links that get broken...because the people managing the cad library are always doing cleaning and renaming as their library grows.. Image the phone company needing to reestablish all the phone connections because they happen to add another digit because 1-999-999-9999 has been maxed out. What we have is old paradigms being stretched to the maximum.

-

Electrical Switches, Outlets, and Cover Plate symbols?

digitalcarbon replied to Bruce Kieffer's topic in General Discussion

Bruce, that is stellar work!