Amorphous - Julian

-

Posts

409 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Marionette

Store

Posts posted by Amorphous - Julian

-

-

2 hours ago, jeff prince said:

It really sounds like you should move your operation to Revit if this is the case. No point in hoping for Vectorworks to be able to keep up with AutoDesk's continually changing proprietary file format. Plus, Revit users are a dime a dozen and you can probably hit at least 3 while swinging your mouse. With Vectorworks abandoning the perpetual license, there's just one more reason to join the dark side. That's just business 101.

Yes @jeff prince, the cost of training someone to operate Vectorworks (1 month salary minimum) just becomes too much for us to take on.

Particularly true when Revit users can come job-ready and start working from day one.That said, I can put up with all the above issues, if Vectorworks actually listens to their users' needs a lot more. Just like the issue of perpetual licence you pointed out, no one likes it, but complaints just fell on deaf ears.

As to whether to turn to the 'dark side' or not... I think it comes down to how much frustration can a paying customer take before they implode.

In the past- before Revit 'became a bit thing'- I felt the VW community was full of love and mutual support... we were all incubating this nifty little software that would one day be great.

At those times, we can forgive the bugs, the workarounds, and the flaws. We discuss how the software can be better. We were all ahead of the technology curve when AutoCad users were still using 2D, and we were already doing 3D BIM!

Now, there is a very developed viable alternative out there, but VW still feels like that incubating software- and we are quickly falling behind.

As we become the underdog/minority, when we ask for improvements/features to VW (because our real-world professional needs require it), we don't need to hear about 'why that can't be done'. We need to hear - 'sure, we will do everything to make sure your professional needs are met'.

Vectorworks needs to completely change its attitude with in 1-2 years in terms of responding to real-world user need cases. Otherwise, it's going to become the Kodak in the digital camera age (didn't take on challenges head-on, and disappeared into oblivion).

Vectorworks should have flooded the market with free versions of its software 3 years ago (just as Autodesk did with Revit)... it's not too late still. The only way it will survive IMHO.

Back to the point about frustration... as architects we have years of training to 'listen'. We listen to our customers' problems and think about how to solve it. Talking to VW engineers, you don't get the sense they had the same training. If they were trained at listening, it could have deflected a lot of the frustrations I see on this forum.

PS... just to share an anecdote, just last week I interviewed someone who liked our office, but was hesitant to join.... 'because we use Vectorworks'... he didn't want to use a software 'that will be no more' in 3 years.-

4

4

-

-

Allow me to join in this conversation, as Revit export capabilities is actually of incredible importance for my office as Vectorworks users. And I think our experience can equally apply to majority of VW users who need to collaborate with others.

The importance of this Revit interoperability is particularly true in our region (Hong Kong), where 98% of BIM is Revit. Revit submission is required for all government projects and most private projects here.

No one (clients or consultants) are interested to hear ‘why’ we can’t give them a proper Revit model.

For your information, from a user POV, Vectorworks export to Revit is very time-consuming and buggy at best.

We would, in our office, leave our models to ‘export to Revit’ overnight. And after hours of overnight churning, we might- the morning after- realise the settings were wrong or the exported Revit model was incomplete. By that time, ‘exporting again’ would be too late so we’d be forced to send a broken model.

When I last enquired about this issue, I was informed by Vectorworks that the Revit export plugin is ‘provided by third party’ and hence there is no way for Vectorworks to improve the performance or reliability of Revit export.

This is really not good enough.

It is up to vectorworks to give us a good and accurate export Revit plugin, so we don’t embarrass ourselves with taking a long time just to provide our clients/consultants with broken Revit models.

if the third party plugin is not good enough- and is not performing properly. Then would Vectorworks please develop one?

As a multiple-licence holder of Vectoworks Designer. I implore you to not ‘hand us to over to the dark side’ and join Revit monopoly. I am now in the process of exploring converting our office to a dual-platform office to run both VW and Revit. It pains me to do such as thing, as I’m a long time VW supporter and have spent so much time developing VW processes in my office.

We need your support (ie all of Vectorworks as a corporation) to carry out our work as a professionals…. And not your excuses (because those who pays for our services are not interested in our excuses, we must pass this responsibility back onto you, who we pay).

It is pointless to deny RVT format is becoming the standard in BIM, just like DWG drawings are in CAD. (All the BIM compatible platforms I work with now talk about ‘direct Revit upload’, not IFC). The game now is about how we can play better with Revit formats in a proactive way.

So @Eric Gilbey, PLA can we please have an answer that sounds less like an excuse why we ‘can’t’ work better with Revit, but give us a roadmap to how we ‘can’?

I reiterate that we are in this to fight the monopoly together. But you guys need to do a lot more on this front to help us, help you.

-

2

2

-

-

@KIT KOLLMEYER as I am now considering moving my office from VW (due to their new licensing model, which I believe spells the end of this software), I am wanting to find out what others were able to sell it for... if you don't mind sharing.

-

I’d like to reiterate a point I made in another post, too….

In the past, transferred perpetual licenses were upgradable.

That is why I subsequently invested in several perpetual licences- they had resell value.

In a single stroke, Vectorworks devalued all perpetual licences- by removing the VSS subscription rights of transferred perpetual licenses.

As someone who forked out money to support this software... of course, I am not happy to see my investment in devalued that way.... but what can I do. The decision was unilateral.I was of course quite upset that my investment was reduced to nothing overnight. I’m not talking about one or two licences….

Original thread as follows

-

1

1

-

-

On 12/1/2022 at 12:06 AM, shorter said:

I think their values remains to be detemined. The option of buying a secondhand perpetual license you can use for as long as you like without further payment (until it stops working) will be quite appealing to some. When I am asked if I know anyone selling it is usually because the buyer wants to reduce costs, not because they think it's a cheap upgrade path.

However, if you can buy now under the current 30% off promotion, and add VSS, it will give you a bit of cost certainty for a few years still, we hope, whether by renewing the VSS each year or by sticking and seeing how long your license will last for.

In the past, transferred perpetual licenses were upgradable.

That is why I subsequently invested in several perpetual licences- they had resell value.

In a single stroke, Vectorworks devalued all perpetual licences- by removing the VSS subscription rights of transferred perpetual licenses.

As someone who forked out money to support this software... of course, I am not happy to see my investment in devalued that way.... but what can I do. The decision was unilateral.

-

4

4

-

-

Any updates @Matt Panzer? Thanks

-

5 hours ago, line-weight said:

Thank you @line-weight

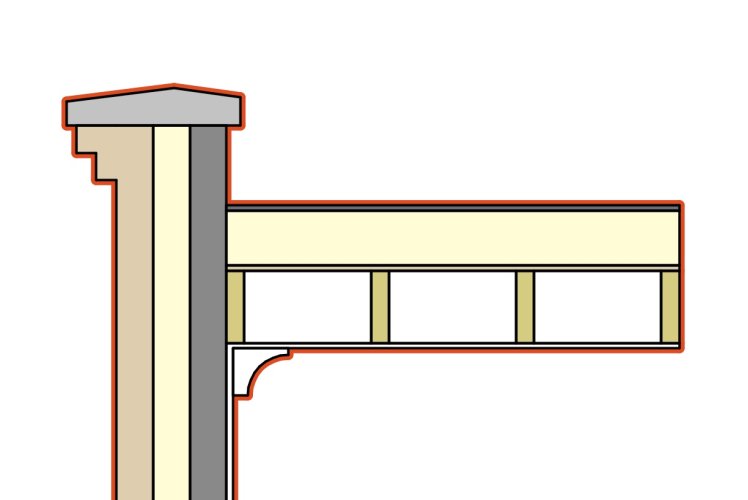

In my office, we manually trace over viewports to achieve this thick section cut line you showed in the above image. It is time-consuming and drives me nuts!

And everytime the model changes, we have to modify this manual think cut line. I hope something more intuitive and relevant to real-world use case can would soon be available.-

2

2

-

-

i think we should consider both scenarios of ‘drawing for Archiecture’ (ie 1:100 scale) and ‘drawing for interiors’ (ie 1:20 scale)

what you said is true for the former but not the latter. For the latter we just want the outermost sectioned object line thickened (be it wall, windows, joinery, fitment). So I think the option of what to thicken should be given to the user and not predetermined by default.

-

In both Enccape and Lumion, this is a simple feature called 'two-point-perspective'.

It is the basis to make renders look good.

Everyone who works at my office is bewildered why Vectorworks doesn't have this.-

3

3

-

-

In encape, and lumion, this function is called 'Two-Point perspective', and there is button for that. And it doesn't change the height you look from or to

-

Thank you @Matt Panzer for your detailed explanation on the difficulty of implementation.

Coming to rethink what I was asking in the original post - I guess there are three components to my suggestion:

(1) Firstly, it is to reduce the number of wall styles required, just to get the model/ drawings looking right, with real world construction sense

(2) Secondly, it is to easily change the finishes of a room / exterior finishes of a building (as a design tool)

(3) Thirdly, it is to easily use Data Tag to tag the finishes of each vertical surface in elevation view

So, after considering your points, I can see how it would be technically different to implement the first point so I no longer insist on it. On the other hand, I would like to make a suggestion that should be highly implementable (for engineers) related to my the second point: To allow component 'classes' to be changed within 'Object Info Palette' for un-styled walls.

So, if we need to quickly test different finishes options for a space, we just 'unstyle' a few walls within a room, and within the OIP change the finishes of the outermost component other material classes, and can instantly see what it looks like. Do you think this can be done?

Following this logic, it would also be great if certain wall style would only carry the 'construction' of a wall, instead of specific materials. In this case the 'finishes class' selected in the OIP can override any finishes of the wall style itself. That way, even if we switch the 'construction' of a wall to dry wall style (or whatever else), the finishes already selected won't change along with it.

The third point (finishes tag for outermost layer), I don't know whether its possible @Matt Panzer, but since we define our material by class in our office, I would love a data tag to only call out the 'class name' of the outermost component of a wall.

And I second @Matt Overton point on demarcation. Core / shell and fitout are usually different contractors. If we were to only be involved with 'interior fitout' for a certain project, and we are given an IFC model. What would be the best practice to put our finishes thicknesses over the core walls provided to use in the IFC? If finihses are to be modelled as a 'wall' over the IFC core wall, how do we make these finishes automatically pick up the openings of the core walls?-

1

1

-

-

I'm bumping this suggestion up as we in our office still build composite walls as separate layers of walls over each other... it is quite ridiculous a workaround.

-

1

1

-

-

Does this include Vectorworks Service Select subscription?

-

What we do as a workaround is to have multiple sheets set up and move the worksheet up on each page to show a different part of the worksheet

Another ridiculous workaround haha-

3

3

-

-

No news on this I guess

-

Seeking 3years+ drafter/modellers to support on various projects.

We are working on a number of projects including high-end residential, school, and F&B.

You will work into our teamwork environment, and the work is to be done remotely.

Interested candidates please send your folio and expected hourly rate to hr@amorphous.com-

1

1

-

-

Oh I missed that... I thought Catalina was sufficient.

So if we press 'update' while in the redshift mode, does it just give us a renderworks render @zoomer? -

While we are on the issue of drawing referencing, @Matt Panzer- is there a way we can do a lined 'reverse reference' drawing title for a detail?

-

@jason schneider refer to above post (also vote it up).

By the way, we really need a dedicated moderator for this forum. This moderator should group together topics asked by people on the forum.

Otherwise the feature request list will keep growing (and duplicating), and Vectorworks will never get through the list of requests.-

3

3

-

-

On 12/12/2020 at 2:55 AM, CollaborativeMT said:

VW should recognize that you are:

- typing a number list hitting return and indenting,

- by starting another number, etc. just like the above visor.

If we can get 'tables' and 'sections' with the text tool, that would even be better.

We would love to do all our specification within one program, and if Vectorworks can either 'link to' a word document and 'place' the contents, or simply have good text editing functions, it would make our workflow so much better.-

2

2

-

I need to bump this post again because we sorely need COMMAND+PERIOD to terminate processes, particularly generating viewport renderings during a publish.

We've now gone through 3 revisions of Vectorworks since this first post. Can some attention be given to this already?-

4

4

-

-

We run into this problem a lot. Very frustrating

-

-

This would be very helpful for the following:

- Export partial model for rendering (whole models are always- Export partial model for contractors to study one detail

- Export partial model for engineer

Please vote this up if this can help your workflow

-

1

1

-

List of forum improvement requests

in Forum Feedback

Posted · Edited by Amorphous - Julian

Sometimes as we post a feature request, we are not aware the same feature (or similar features) was already submitted in previous posts.

Hence, it would be good if:

(1) moderator or AI combines these same or similar posts

(2) if a poster later realises there is a similar post in the past, be given the ability to request the posts to be combined

(3) all combined posts should combine the upvotes too

Also, in terms of old unprocessed posts:

(a) all unprocessed posts with 5 upvotes or more should be revisited by the moderators on a yearly basis.

(b) reason for the unprocessed posts should be given: eg ‘already addressed in version 2024’, ‘under review’, ‘engineering infeasible’, ‘in future roadmap’, ‘awaiting more upvotes’…. Etc.

It’s can be very discouraging to see posts that have up to say 10 upvotes, sitting here in the forum for 5-10 years, still not acknowledged or addressed.